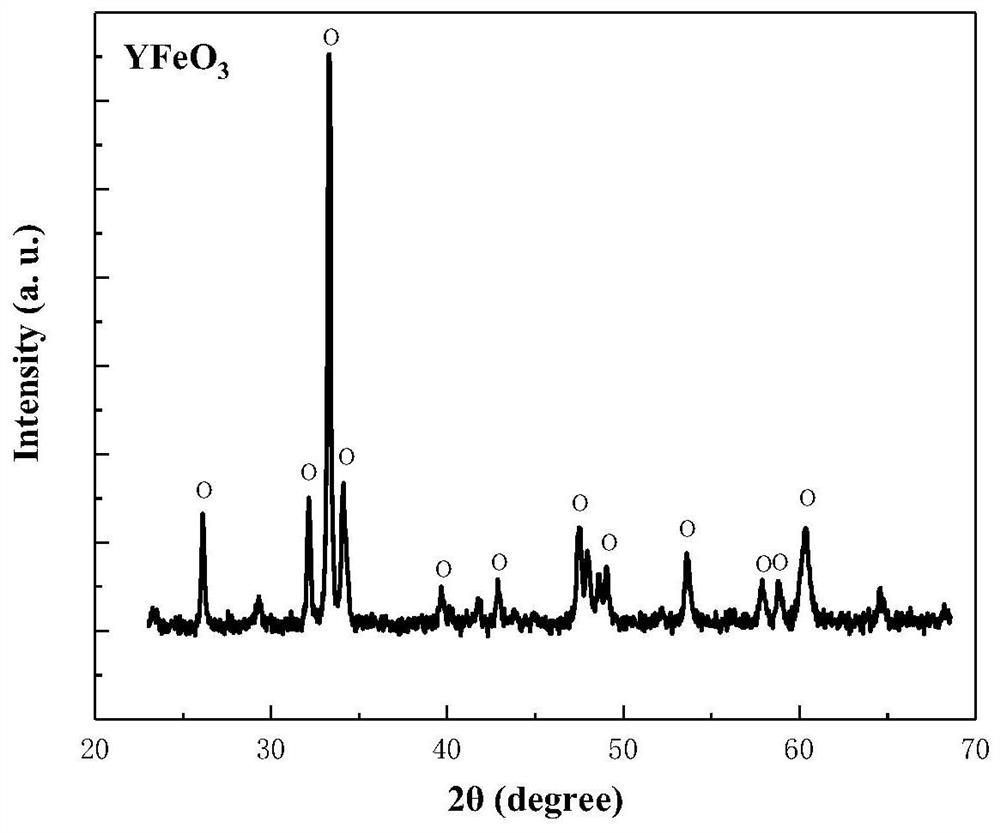

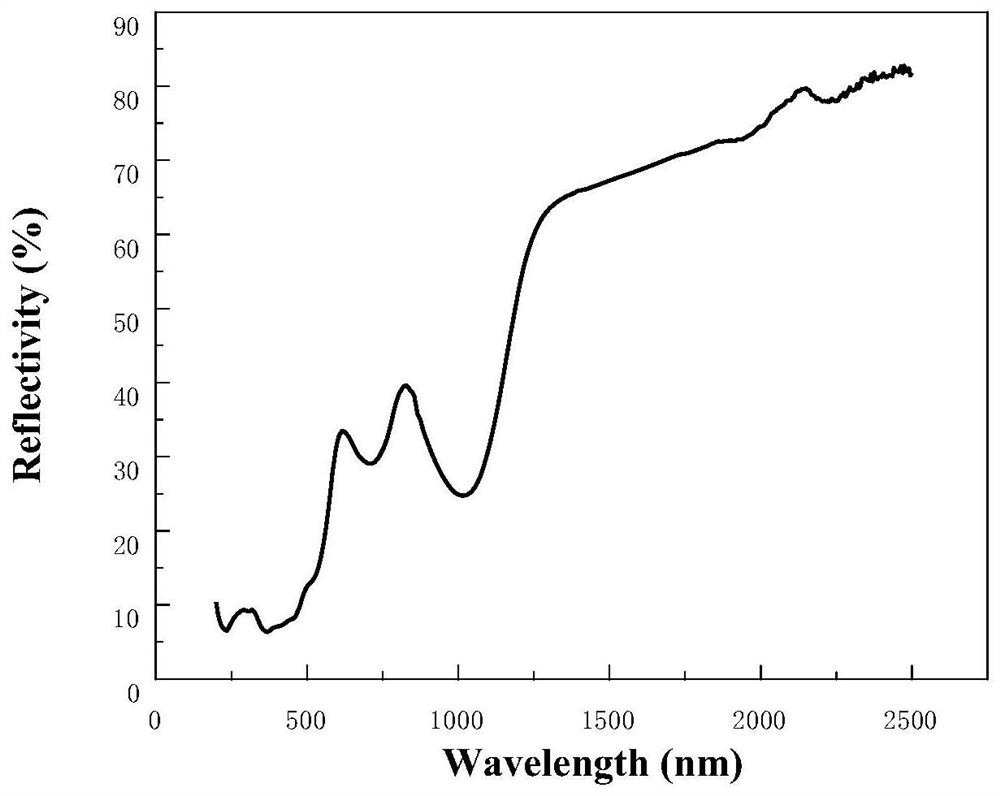

Yttrium ferrite powder with high near-infrared reflectivity and preparation method thereof

An infrared reflection, yttrium ferrite technology, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of long production cycle, complex process, and high equipment requirements, and achieve short production cycle, simple process, and equipment requirements. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A high near-infrared reflectance yttrium ferrite powder and a preparation method thereof. The specific steps of the preparation method described in this embodiment are:

[0029] The first step, by yttrium nitrate hexahydrate: ferric nitrate nonahydrate: citric acid monohydrate: the ratio of the amount of ethylene glycol is 1:1:2:2, the yttrium nitrate hexahydrate, the nonahydrate Ferric nitrate, the citric acid monohydrate and ethylene glycol are mixed to obtain a mixture.

[0030] In the second step, the mixture is ground for 30 minutes at room temperature, and then dried at 100° C. for 12 hours to obtain a precursor of yttrium ferrite.

[0031] The third step is to grind the yttrium ferrite precursor for 11 minutes to obtain a grinding material, put the grinding material into a corundum crucible, and then place the corundum crucible in a muffle furnace at a rate of 4°C / min Raise the temperature to 900°C, keep it warm for 4 hours, cool down with the furnace, and take...

Embodiment 2

[0033] A high near-infrared reflectance yttrium ferrite powder and a preparation method thereof. The specific steps of the preparation method described in this embodiment are:

[0034] The first step, by yttrium nitrate hexahydrate: ferric nitrate nonahydrate: citric acid monohydrate: the ratio of the amount of ethylene glycol is 1:1:4:3, the yttrium nitrate hexahydrate, the nonahydrate Ferric nitrate, the citric acid monohydrate and ethylene glycol are mixed to obtain a mixture.

[0035] In the second step, the mixture was ground for 60 minutes at room temperature, and then dried at 110° C. for 2 hours to obtain a precursor of yttrium ferrite.

[0036] The third step is to grind the yttrium ferrite precursor for 13 minutes to obtain a grinding material, put the grinding material into a corundum crucible, and then place the corundum crucible in a muffle furnace, at a rate of 3°C / min Raise the temperature to 850°C, keep it warm for 3 hours, cool with the furnace, and take it ...

Embodiment 3

[0038] A high near-infrared reflectance yttrium ferrite powder and a preparation method thereof. The specific steps of the preparation method described in this embodiment are:

[0039] The first step, by yttrium nitrate hexahydrate: ferric nitrate nonahydrate: citric acid monohydrate: the ratio of the amount of ethylene glycol is 1:1:6:5, the yttrium nitrate hexahydrate, the nonahydrate Ferric nitrate, the citric acid monohydrate and ethylene glycol are mixed to obtain a mixture.

[0040] In the second step, the mixture was ground for 90 minutes at room temperature, and then dried at 100° C. for 8 hours to obtain a precursor of yttrium ferrite.

[0041] The third step is to grind the yttrium ferrite precursor for 10 minutes to obtain a grinding material, put the grinding material into a corundum crucible, and then place the corundum crucible in a muffle furnace at a rate of 5°C / min Raise the temperature to 1000°C, keep it warm for 5 hours, cool down with the furnace, and tak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com