Potassium sodium niobate-based transparent ceramic material and preparation method thereof

A potassium-sodium niobate-based, transparent ceramic technology, which is applied in the field of transparent ceramic materials, can solve the problems of low crystal symmetry, poor mechanical strength, and low dielectric constant, and achieve high density, good crystallinity, and grain size uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

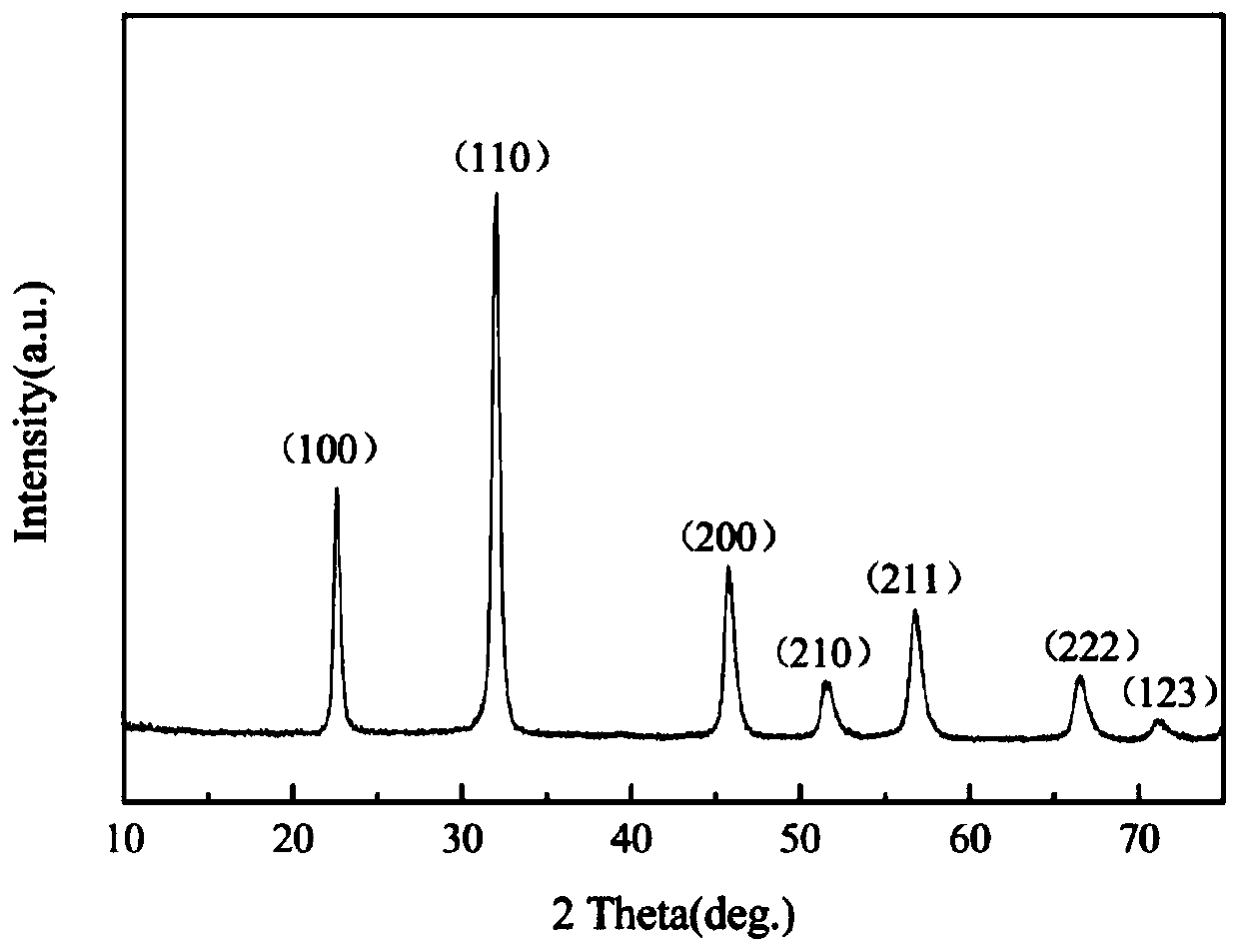

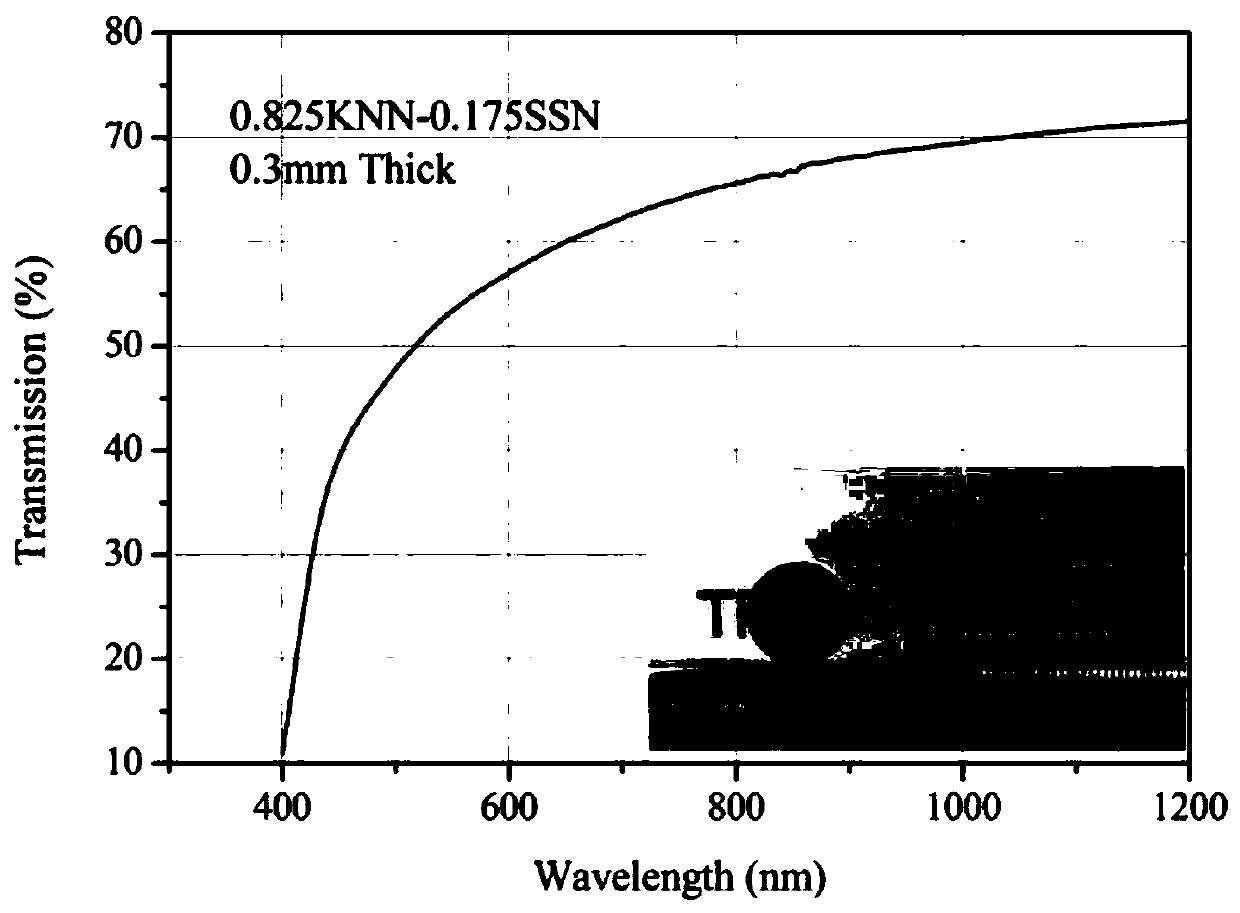

[0032] combine Figure 1~3 , the present embodiment provides a kind of component raw material and its molar percentage content is (1-x) (K 0.5 Na 0.5 )NbO 3 -xSr(Sc 0.5 Nb 0.5 )O 3 The preparation method of potassium sodium niobate base transparent ceramic material comprises the following steps:

[0033] The first step: ingredients, first calculate the K of each component in the powder raw material according to the composition of the above chemical formula 2 CO 3 、Na 2 CO 3 , Nb 2 O, SrCO 3 、Sc 2 o 3 The quality of the mixture is prepared according to the composition ratio, and ball milling is carried out after mixing to obtain a mixed powder; then the first ball milling is carried out, the mixture is added to the ball milling medium, put into a ball milling tank and ball milled for 10 hours, the ball milling speed is 350r / min, and the ball milling is over Finally, the mixture is dried in an oven at a temperature of 80° C., and sieved through a 60-80 mesh screen t...

Embodiment 2

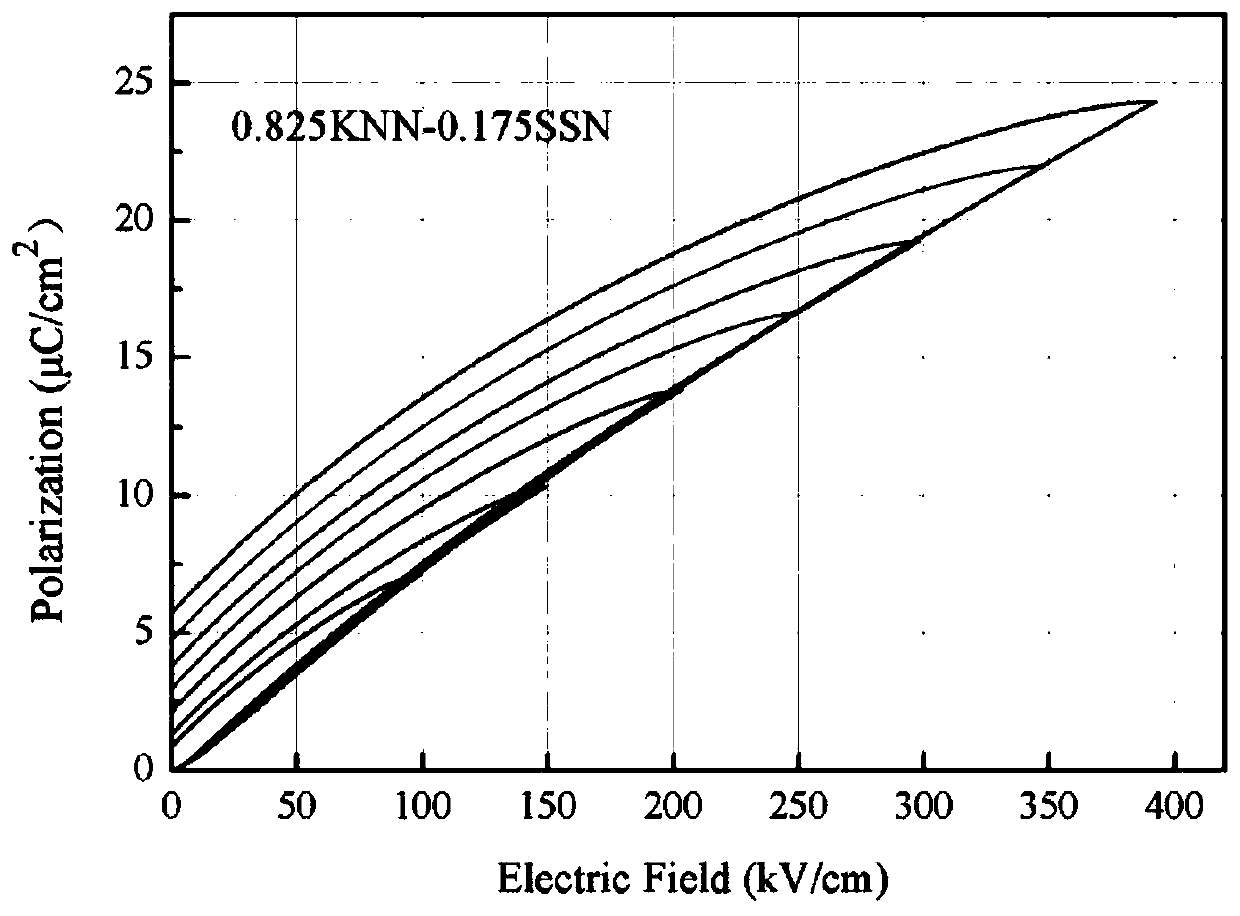

[0044] Prepare a kind of potassium sodium niobate base transparent ceramic material according to the preparation method described in embodiment 1, and component is 0.85 (K 0.5 Na 0.5 )NbO 3 -0.15Sr(Sc 0.5 Nb 0.5 )O 3 , the ferroelectric properties of different electric fields at room temperature were tested, and the hysteresis loop is as follows Figure 4 . The maximum polarization intensity is 18.14μC / cm 2 , the remnant polarization is 2.47μC / cm 2 , the maximum breakdown field strength is 265kV / cm energy storage density W = 2.0657J / cm 3 , the reversible energy storage density W rec =1.593J / cm 3 , the efficiency η is 77.12%.

Embodiment 3

[0046] Other conditions are the same as in Example 1, except that the sintering temperature is 1266°C. There are micropores in the potassium sodium niobate-based transparent ceramics prepared at this sintering temperature, and the breakdown electric field is 250kV / cm. Its hysteresis loop is relatively fat, although P max The value is larger, but at the same time P r value is too large, causing its W rec Only 1.2J / cm 3 , η is only 46%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com