Method for preparing composite wave-absorbing material and the prepared composite wave-absorbing material

A composite absorbing material and sub-micron technology, applied in the field of nanomaterials, can solve the problems of poor weather resistance, narrow absorbing frequency band, easy agglomeration, etc., and achieve the effects of optimizing absorbing performance, increasing absorbing capacity and stabilizing reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] Preparation of nickel submicron spheres

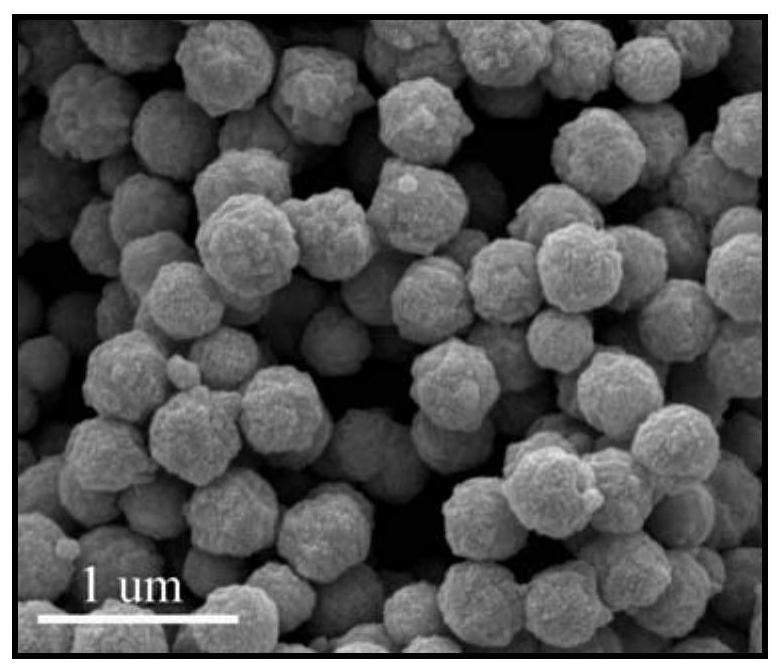

[0044] NiCl 2 ·6H 2 O (1.2g), sodium acetate (3.0g) and trisodium citrate dihydrate (0.2g) were dispersed in a mixed solution of glycerol (30mL) and distilled water (10mL); after stirring for 1.5h, the homogeneous suspension Transfer to a Teflon-lined stainless steel autoclave; dissolve sodium hydroxide NaOH (1.6 g) and sodium hypophosphite monohydrate NaH in 20 mL of distilled water 2 PO 2 ·H 2 O (3.2 g) was slowly poured into the autoclave, and after reacting at 140° C. for 15 h, the solution was cooled to room temperature. Wash the resulting gray precipitate several times with distilled water and absolute ethanol, collect it with a magnet, and finally dry it under vacuum at 60°C for 12 hours to obtain the product nickel submicron spheres. The SEM image of the resulting nickel submicron spheres can be found in figure 1 , it can be seen that the nickel submicron spheres are uniformly dispersed.

[0045] Preparation of ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com