Sulfuric acid slag composite explosion suppression material capable of inhibiting coal dust explosion and preparation method and application thereof

A sulfuric acid slag and coal dust technology, applied in dust prevention, mining equipment, earthwork drilling, etc., can solve problems affecting sintering productivity, high water absorption, poor ball formation, etc., achieve excellent explosion suppression effect, expand utilization channels, Realize the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

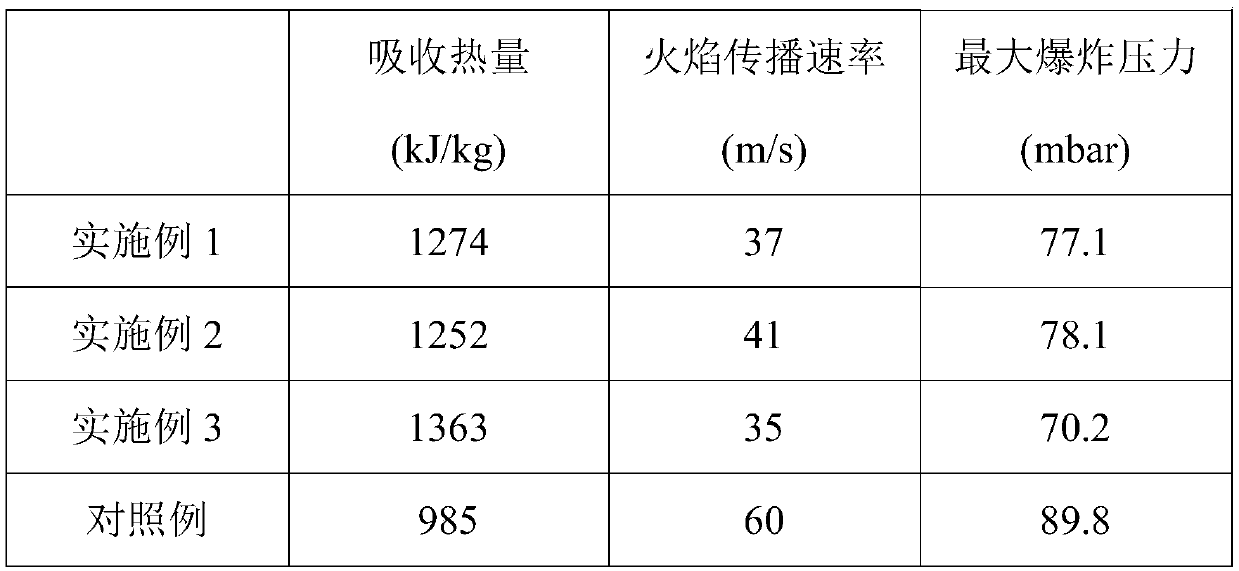

Examples

Embodiment 1

[0042] A kind of preparation of the sulfuric acid slag composite anti-explosion material of suppressing coal dust explosion, comprises the following steps:

[0043] (1) After stirring 40 parts by weight of sulfuric acid slag powder, 5 parts by weight of coal powder, 3 parts by weight of gypsum, 10 parts by weight of calcium oxide and 2 parts by weight of water, the briquetting is dried, calcined at 1000 ° C for 3 hours, cooled After grinding to 100 mesh, active powder is obtained.

[0044] (2) 40 parts by weight of active powder soaked in 180 parts by weight of calcium hydroxide solution, 1 part by weight of aluminate coupling agent, 28 parts by weight of sodium hexametaphosphate and 1 part by weight of ammonium persulfate as 180 parts by weight of calcium hydroxide solution with a mass concentration of 5%. In the oxidizing agent, after stirring at 50°C for 6 hours, separate the obtained upper layer flocculent turbid liquid and the lower layer residue after completion, and set...

Embodiment 2

[0049] A kind of preparation of the sulfuric acid slag composite anti-explosion material of suppressing coal dust explosion, comprises the following steps:

[0050] (1) After stirring 60 parts by weight of sulfuric acid slag powder, 8 parts by weight of coal powder, 6 parts by weight of gypsum, 14 parts by weight of calcium oxide and 4 parts by weight of water, the briquetting is dried, calcined at 1080 ° C for 2 hours, cooled After grinding to 300 mesh, active powder is obtained.

[0051] (2) Soak 60 parts by weight of active powder in 230 parts by weight of calcium hydroxide solution, 3 parts by weight of aluminate coupling agent, 15 parts by weight of sodium hexametaphosphate and 3 parts by weight of ammonium persulfate as 230 parts by weight of calcium hydroxide solution with a mass concentration of 6%. In the oxidizing agent, after stirring at 50°C for 5 hours, after completion, separate the obtained upper layer flocculent liquid and the lower layer residue, and set aside...

Embodiment 3

[0056] A kind of preparation of the sulfuric acid slag composite anti-explosion material of suppressing coal dust explosion, comprises the following steps:

[0057] (1) After stirring 70 parts by weight of sulfuric acid slag powder, 10 parts by weight of coal powder, 10 parts by weight of gypsum, 20 parts by weight of calcium oxide and 5 parts by weight of water, the briquetting is dried, calcined at 1100 ° C for 2 hours, and cooled After grinding to 80 mesh, active powder is obtained.

[0058] (2) 50 parts by weight of active powder soaked in 200 parts by weight of calcium hydroxide solution, 2 parts by weight of aluminate coupling agent, 20 parts by weight of sodium hexametaphosphate and 2.1 parts by weight of sodium persulfate as 200 parts by weight of calcium hydroxide solution with a mass concentration of 9%. In the oxidizing agent, after stirring at 60°C for 4 hours, separate the obtained upper flocculent turbid liquid from the lower residue and set aside for later use; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com