A sulfur dioxide recycling system and method

A sulfur dioxide and resource recovery technology, applied in chemical instruments and methods, thiosulfate/dithionite/polythionate, inorganic chemistry, etc., can solve high cost, low production cost of by-products, and product capacity To reduce the overall investment of the system, ensure ultra-low emissions, and improve operational flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

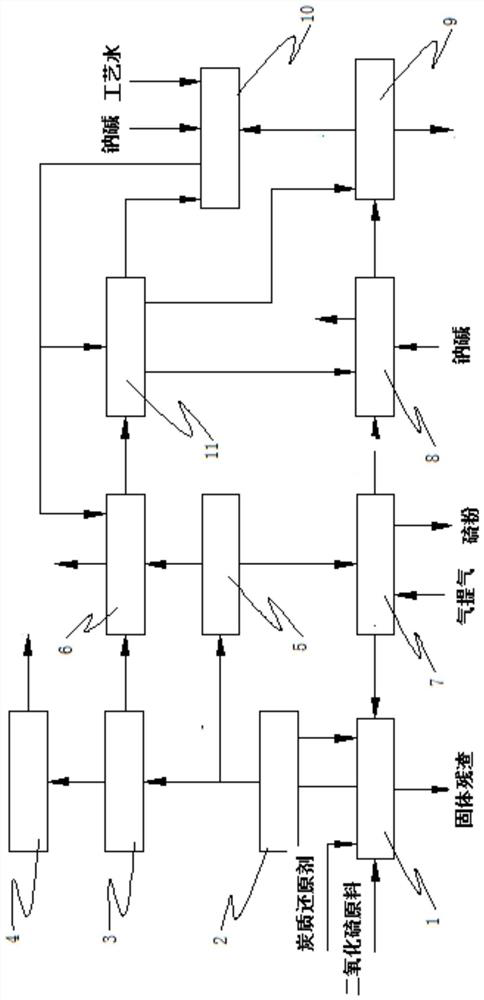

[0042] Embodiment 1 synthetic sodium thiosulfate and sulfur powder

[0043] ①. Preparation of elemental sulfur: In the carbonaceous reduction furnace, white coal, carbon fines, coke, high-sulfur coal or petroleum coke are used as conventional carbonaceous reductants and SO-containing 2 The original flue gas undergoes redox reaction to generate process gas containing gaseous sulfur, and the volume content of oxygen in the process gas is controlled below 1.5%. In the carbon reduction furnace, it can be divided into ash cooling section, SO 2 The reduction section, the reductant preheating section, and the lower part of the ash cooling section are controlled at 250~380°C, SO 2 The temperature of the reducing section is controlled at 860~1100°C, and the temperature of the upper part of the reductant preheating section is controlled at 380~650°C; the carbonaceous reducing agent and sulfur-containing flue gas SO 2 The mass metering ratio is M1:M2=1:(3~8), where M 1 is the mass flo...

Embodiment 2

[0058] Embodiment 2 sodium thiosulfate and liquid sulfur

[0059] ①. Preparation of elemental sulfur: In the carbonaceous reduction furnace, white coal, carbon fines, coke, high-sulfur coal or petroleum coke are used as conventional carbonaceous reductants and SO-containing 2 The original flue gas undergoes redox reaction to generate process gas containing gaseous sulfur, and the volume content of oxygen in the process gas is controlled below 1.5%. In the carbon reduction furnace, it can be divided into ash cooling section, SO 2 The reduction section, the reductant preheating section, and the lower part of the ash cooling section are controlled at 250~380°C, SO 2 The temperature of the reducing section is controlled at 860~1100°C, and the temperature of the upper part of the reductant preheating section is controlled at 380~650°C; the carbonaceous reducing agent and sulfur-containing flue gas SO 2 The mass metering ratio is M1:M2=1:(2~8), where M1 is the mass flow rate of fi...

Embodiment 3

[0076] Embodiment 3 Preparation of liquid sulfur and sodium sulfite

[0077] ①. Preparation of elemental sulfur: In the carbonaceous reduction furnace, conventional carbonaceous reducing agents such as white coal, carbon fines, coke, high-sulfur coal, petroleum coke and SO containing 2 The original flue gas undergoes redox reaction to generate process gas containing gaseous sulfur, and the volume content of oxygen in the process gas is controlled below 1.5%. In the carbon reduction furnace, it can be divided into ash cooling section, SO 2 The reduction section, the reductant preheating section, and the lower part of the ash cooling section are controlled at 250~380°C, SO 2 The temperature of the reducing section is controlled at 860~1100°C, and the temperature of the upper part of the reductant preheating section is controlled at 380~650°C; the carbonaceous reducing agent and sulfur-containing flue gas SO 2 The mass metering ratio is M1:M2=1:(2~8), where M1 is the mass flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com