Drilling waste sulfonated mud treatment method

A treatment method and slurry technology, which can be applied in the fields of sludge treatment, oxidation treatment of sludge, chemical instruments and methods, etc., and can solve problems such as inability to eliminate, pollution, and surrounding soil pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

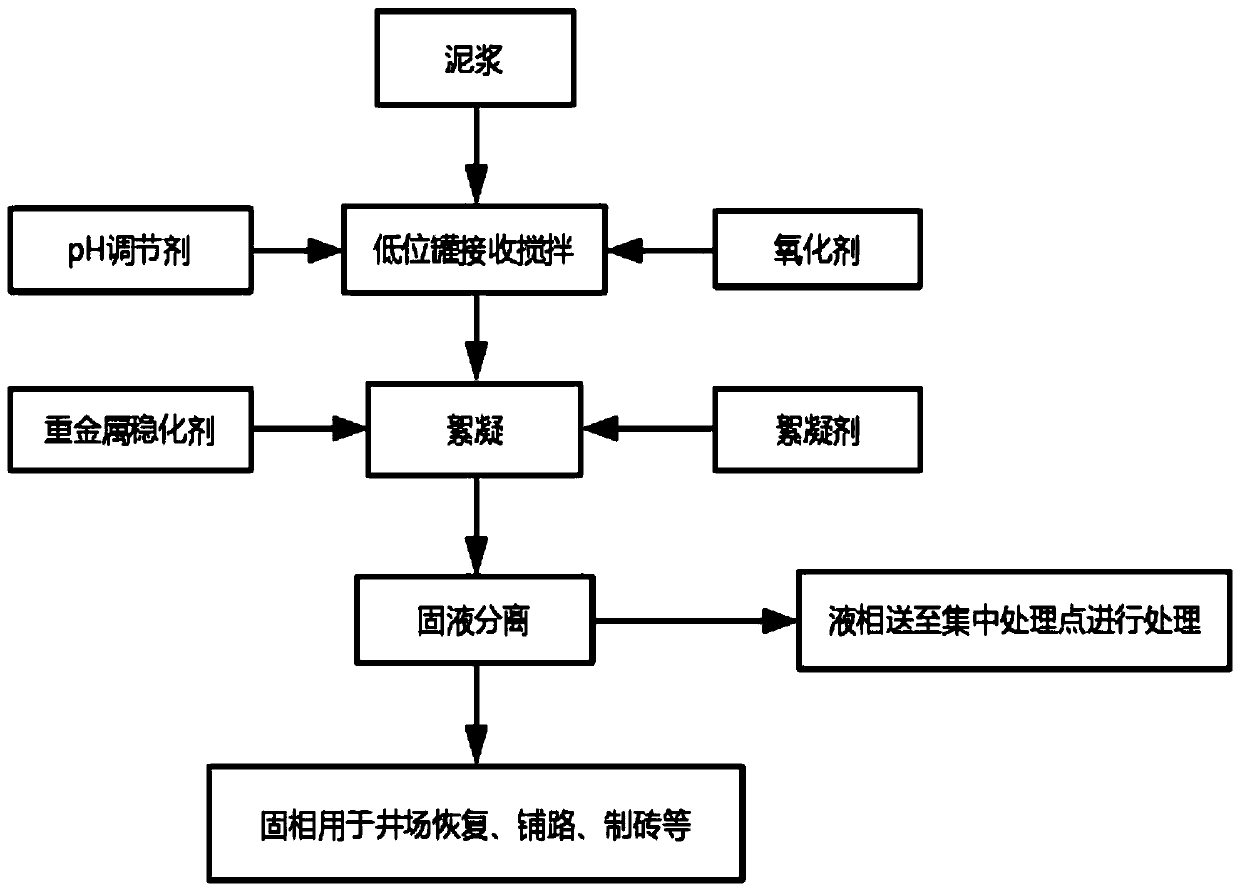

Method used

Image

Examples

Embodiment 1

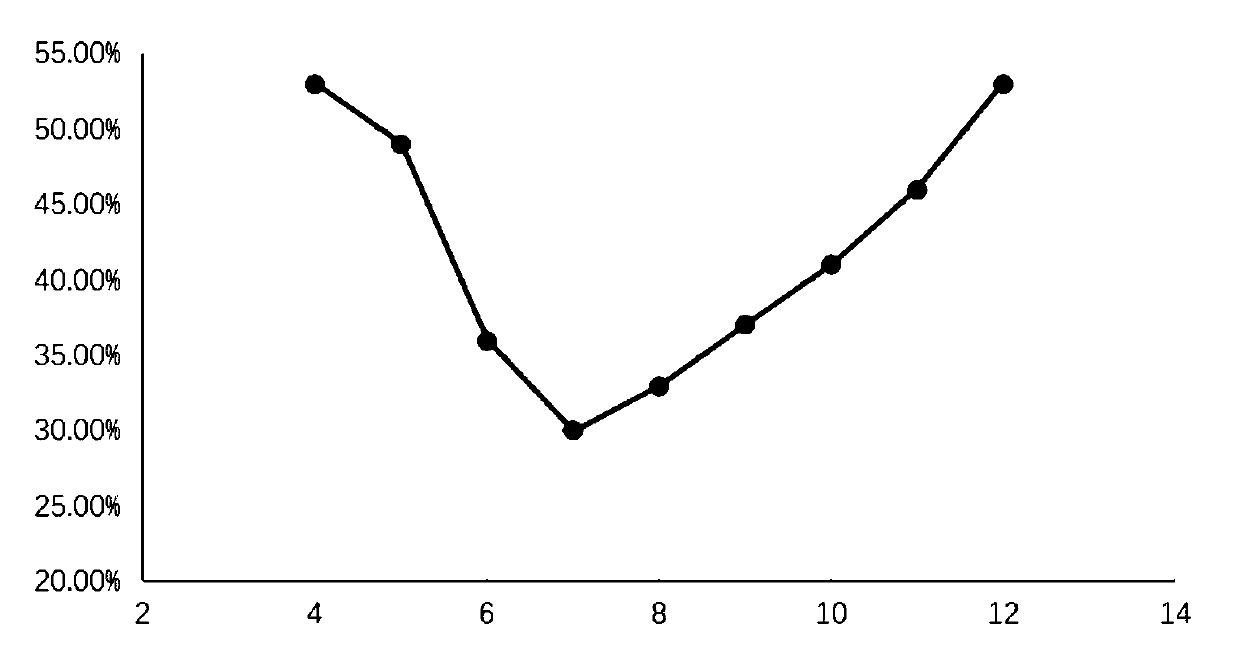

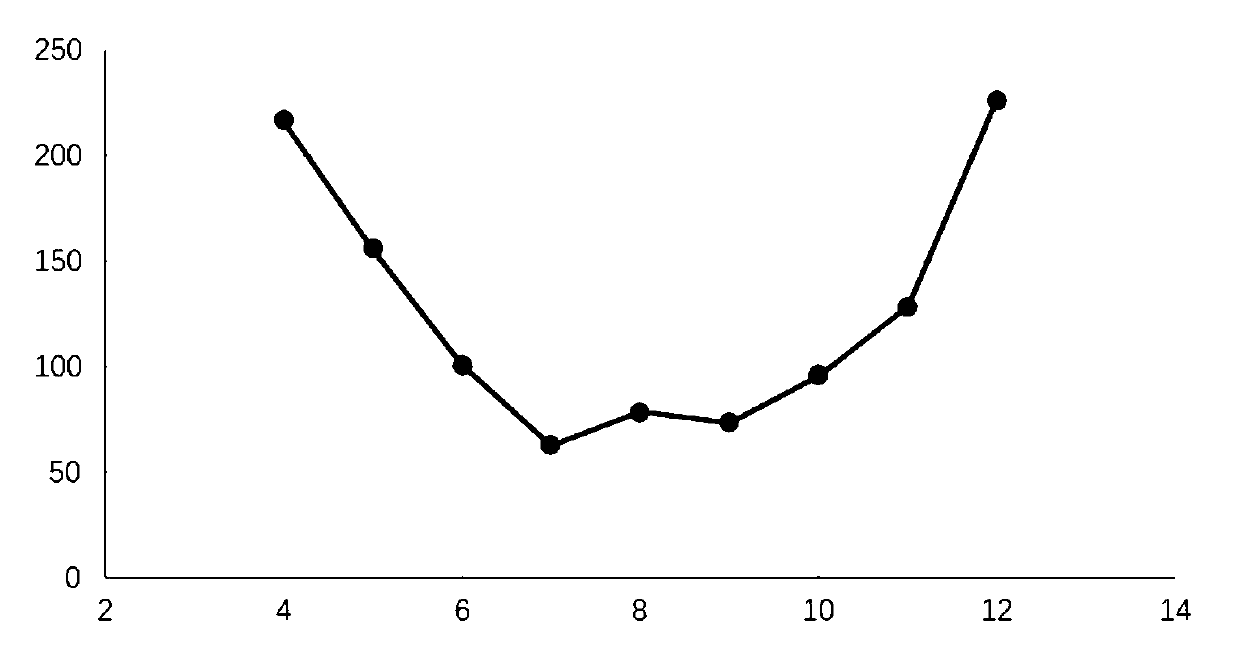

[0034] 1) Collect the waste sulfonated mud from drilling, and adjust the pH value of the mud to 7 with dilute sulfuric acid;

[0035] 2) Add 30wt% concentration of hydrogen peroxide to the pH-adjusted mud, and the addition is 0.8% of the mud volume to oxidize the mud;

[0036] 3) Add EDTA of 0.6wt% concentration in the oxidized mud, and the addition is 4% of the mud volume, so that heavy metal ions in the mud form stable complexes;

[0037] 4) Add the ferrous chloride of 15wt% concentration in the mud that forms stable complex, add-on is 20% of mud volume, mud is carried out gel breaking flocculation;

[0038] 5) Use a vacuum belt filter for solid-liquid separation.

Embodiment 2

[0040] 1) Collect the waste sulfonated mud from drilling, and adjust the pH value of the mud to 6 with citric acid;

[0041] 2) adding permanganate of 40wt% concentration to the mud after pH adjustment, the addition is 1% of the mud volume, and the mud is oxidized;

[0042] 3) Add TMT of 0.8wt% concentration in the oxidized mud, and the addition is 5% of the mud volume, so that the heavy metal ions in the mud form a stable complex;

[0043] 4) adding 0.4wt% polyethylene oxide to the mud forming a stable complex, the addition is 15% of the mud volume, and the mud is broken and flocculated;

[0044] 5) A centrifuge is used for solid-liquid separation.

Embodiment 3

[0046] 1) Collect the waste sulfonated mud from drilling, and adjust the pH value of the mud to 9 with organic phosphoric acid;

[0047] 2) Add 50wt% concentration of H in the pH-adjusted mud 2 o 2 , the addition amount is 0.5% of the mud volume, and the mud is oxidized;

[0048] 3) Adding 0.2wt% concentration of maleic acid acrylic acid copolymer to the oxidized mud, the addition is 2% of the mud volume, so that the heavy metal ions in the mud form a stable complex;

[0049] 4) adding aluminum sulfate at a concentration of 20wt% to the mud forming a stable complex, the addition is 10% of the mud volume, and the mud is broken and flocculated;

[0050] 5) A plate and frame filter press is used for solid-liquid separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com