Paint for pier and bridge decoration and protection and preparation method thereof

A technology for bridge decoration and piers, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problem of not meeting the use of bridge piers and bridges, and achieve the effect of anti-fouling and rain marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

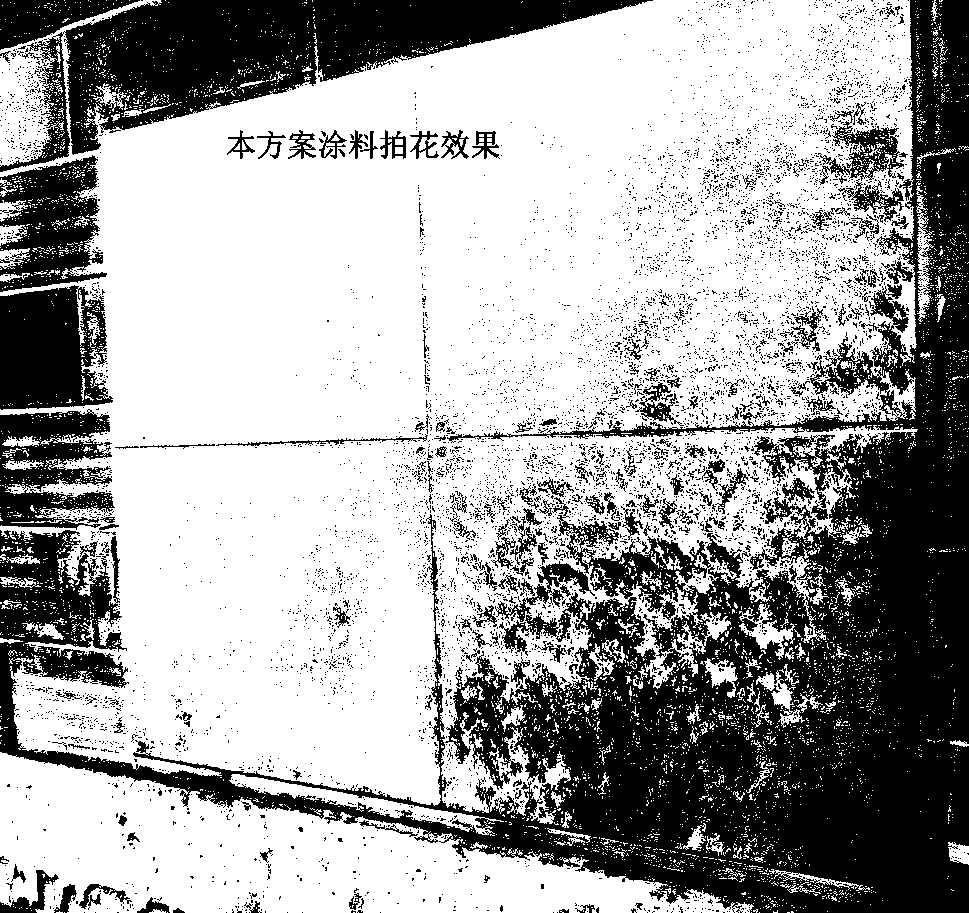

Image

Examples

Embodiment 1

[0038] A kind of coating for pier bridge decoration and protection, comprising by weight: 15 parts of water-based fluorine-containing acrylic resin, 26 parts of K2 silicone resin emulsion, 5 parts of NSR 801 paint film enhancer, 1 part of MK888 methyl Potassium silicate aqueous solution, 0.10 parts of polyphosphate, 10 parts of powder, 0.20 parts of HEC cellulose, 1.7 parts of auxiliary materials; also includes supplementary water.

[0039] The auxiliary materials include 0.1 part of dispersant, 0.8 part of BS 1306 hydrophobic agent, 0.5 part of thickener, 0.10 part of film-forming aid, 0.10 part of preservative, and 0.10 part of defoamer.

Embodiment 2

[0041] A kind of coating for pier bridge decoration and protection, comprising by weight: 17 parts of water-based fluorine-containing acrylic resin, 27 parts of K2 silicone resin emulsion, 5.5 parts of NSR 801 paint film enhancer, 1.2 parts of MK888 methyl Potassium silicate aqueous solution, 0.10 parts of polyphosphate, 10 parts of material powder, 0.20 parts of HEC cellulose, 1.8-3.1 parts of auxiliary materials; also includes supplementary water.

[0042] The auxiliary materials include 0.1 part of dispersant, 0.8 part of BS 1306 hydrophobic agent, 0.5 part of thickener, 0.10 part of film-forming aid, 0.10 part of preservative, and 0.10 part of defoamer.

Embodiment 3

[0044]A kind of coating for pier bridge decoration and protection, comprising by weight: 20 parts of water-based fluorine-containing acrylic resin, 28 parts of K2 silicone resin emulsion, 6 parts of NSR 801 paint film enhancer, 1.4 parts of MK888 methyl Potassium silicate aqueous solution, 0.10 parts of polyphosphate, 12 parts of powder, 0.25 parts of HEC cellulose, 2.0 parts of auxiliary materials; also includes supplementary water.

[0045] The auxiliary materials include 0.15 parts of dispersant, 1.0 part of BS 1306 hydrophobic agent, 0.6 part of thickener, 0.15 part of film-forming aid, 0.15 part of preservative, and 0.15 part of defoamer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com