Method for preparing ecologically improved substrate based on coal gangue and sludge

A coal gangue and sludge technology, applied in the field of solid waste resource utilization, can solve environmental risks and other problems, achieve the effects of improving physical and chemical properties, improving soil fertility, and improving soil physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation of embodiment 1 sludge compost

[0025] The pruned branches of garden trees are crushed into particles below 2cm. The newly generated sludge from the sewage treatment plant is dehydrated. If the rice husk is replaced with mushroom dregs, it is necessary to remove the mushroom sticks from the bag while they are still fresh and crush the corn stalks to a particle size below 3cm), and the sludge composting backmixing material is the previous sludge composting left over decomposed material. Each raw material is calculated by weight, 15 parts of garden tree pruning branches crushed matter, 70 parts of fresh dewatered sludge, 8 parts of rice husk, 7 parts of sludge composting backmixing material, microbial composting decomposing agent (produced by Henan Nongfukang Biotechnology Co., Ltd.) Add 0.1kg per ton of material. Microbial compost decomposing agent is pre-cultivated by adding 3 kg of rice bran and 10 liters of water per kg of bacterial agent for 4-6 ho...

Embodiment 2

[0031] Embodiment 2 is resistant to heavy metal growth-promoting bacterium preparation and the tolerance to heavy metal

[0032] The heavy metal-resistant growth-promoting bacteria agent of the present invention includes the following microorganisms: Acinetobacter sp. NXH1, Klebsiella sp. NXH2, Stenotrophomonas sp. NXH3 and Pseudomonas sp. Bacteria (Pseudomonas sp.) XKS were all preserved on August 23, 2016 in the General Microbiology Center of the China Committee for the Collection of Microbial Cultures (CGMCC for short) (unit address: Courtyard 3, No. 1 Beichen West Road, Chaoyang District, Beijing No., zip code: 100101), its preservation numbers are respectively CGMCC.12895, CGMCC.12896, CGMCC.12897, CGMCC.12894, 5 strains of bacteria are respectively inoculated with beef extract peptone medium at an inoculum size of 10%, and 30 Cultivate on a shaking table at ℃, cultivate Acinetobacter and Stenotrophomonas for 72 hours, and cultivate Klebsiella and Pseudomonas for 48 hours...

Embodiment 3

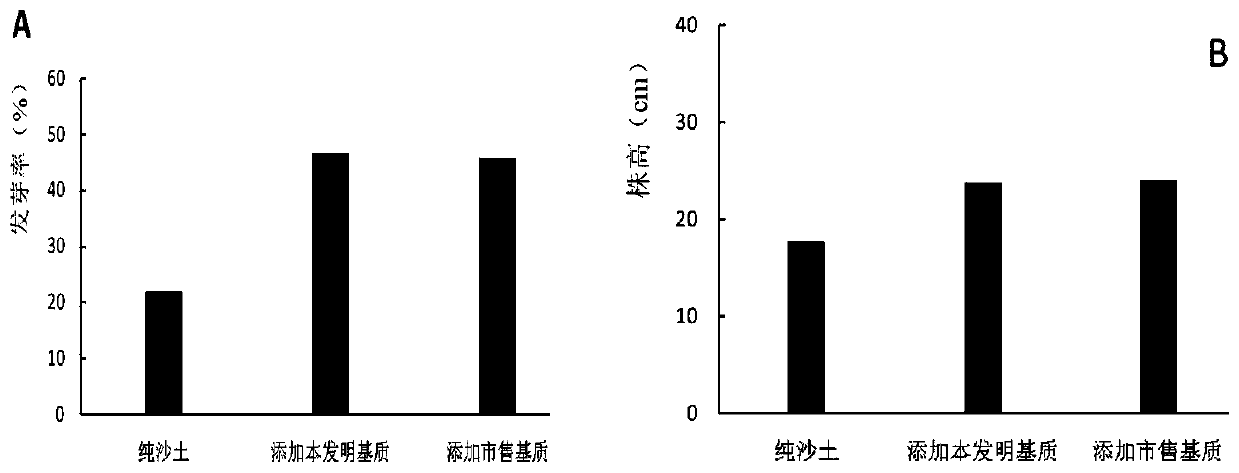

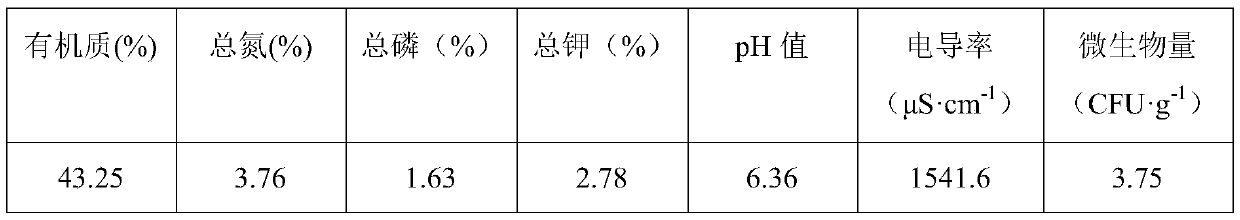

[0036] The preparation of embodiment 3 ecological improvement matrix

[0037] According to the mass ratio, take 60 parts of coal gangue particles crushed below 4 meshes, 30 parts of sludge compost, and 10 parts of fly ash and mix them fully with a forklift or shaker truck. While mixing, spray water on the top of the materials to prevent and control dust. Spray 0.2 parts of the heavy metal-tolerant growth-promoting agent fermentation liquid evenly on the mixed material with a sprayer, then stir and mix, then cover the surface of the substrate with a black plastic film, and leave it for 2 weeks to mature without stirring during the period, that is, To obtain the ecological improvement substrate, in order to compare the effect of the bacterial agent, the treatment without adding the mixed bacterial agent was done at the same time, and the other preparation materials and processes were exactly the same. Two kinds of matrices were taken to measure heavy metal content and microbial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com