Antirust and high-slump-retaining polycarboxylic acid high-performance water reducing agent and preparation method thereof

A slump-preserving type, polycarboxylic acid technology, applied in the field of water reducing agent processing, can solve the problems of high alkali content, retardation, poor slump retention, etc., to achieve the effect of improving dispersion and accelerating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

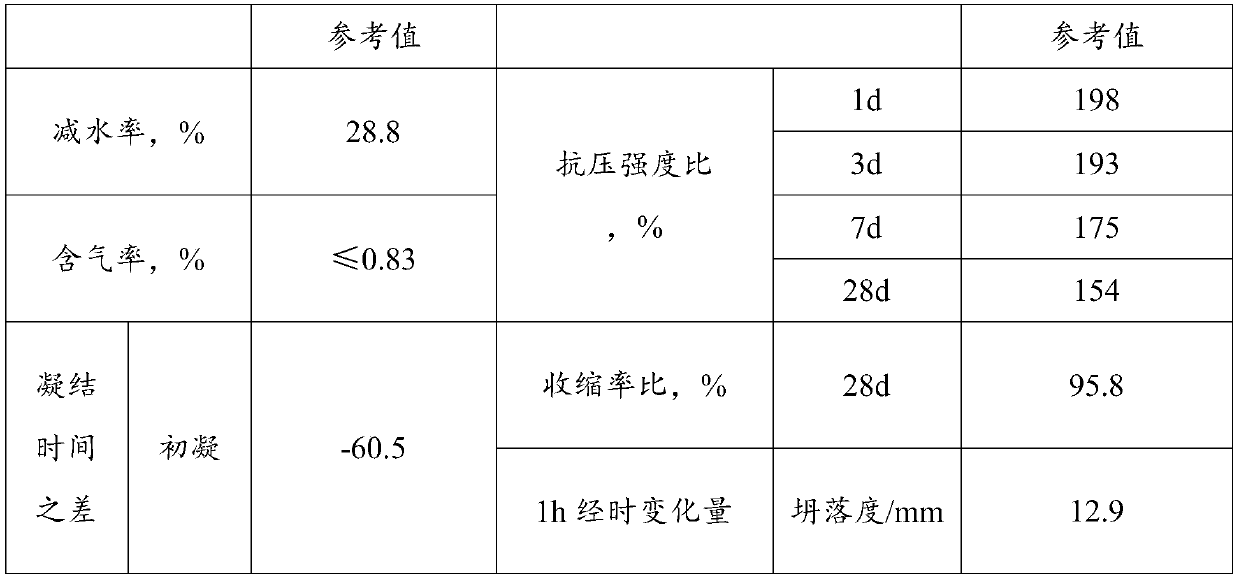

Embodiment 1

[0023] An anti-rust and high-slump polycarboxylate high-performance water reducer is processed from the following raw materials in parts by weight:

[0024] 380 parts of methallyl alcohol polyoxyethylene ether, 3.5 parts of hydrogen peroxide, 2 parts of mercaptopropionic acid, 0.5 parts of vitamin C, 35 parts of acrylic acid, 15 parts of caustic soda, 1-ethyl-(3-dimethylaminopropyl 10 parts of carbodiimide hydrochloride, 5 parts of dimethylacetamide, 8 parts of β-glucan, 5 parts of water-based rust inhibitor, 300 parts of water

[0025] The preparation method of embodiment 1, described method step is as follows:

[0026] Step S1: Put methallyl alcohol polyoxyethylene ether and part of the formula amount of water into the reactor, and heat up to 40±2°C for later use;

[0027] Step S2: adding hydrogen peroxide to the material in step S1, and reacting for a period of time;

[0028] Step S3: Using the remaining amount of water, configure mercaptopropionic acid and vitamin C into...

Embodiment 2

[0031] An anti-rust and high-slump polycarboxylate high-performance water reducer is processed from the following raw materials in parts by weight:

[0032] 400 parts of methallyl alcohol polyoxyethylene ether, 4.5 parts of hydrogen peroxide, 2.5 parts of mercaptopropionic acid, 1.0 parts of vitamin C, 40 parts of acrylic acid, 18 parts of caustic soda, 1-ethyl-(3-dimethylaminopropyl base) 20 parts of carbodiimide hydrochloride, 8 parts of dimethylacetamide, 15 parts of β-glucan, 10 parts of water-based rust inhibitor, and 340 parts of water.

[0033] The preparation method of embodiment 2, described method step is as follows:

[0034] Step S1: Put methallyl alcohol polyoxyethylene ether and part of the formula amount of water into the reactor, and heat up to 40±2°C for later use;

[0035] Step S2: adding hydrogen peroxide to the material in step S1, and reacting for a period of time;

[0036] Step S3: Using the remaining amount of water, configure mercaptopropionic acid and...

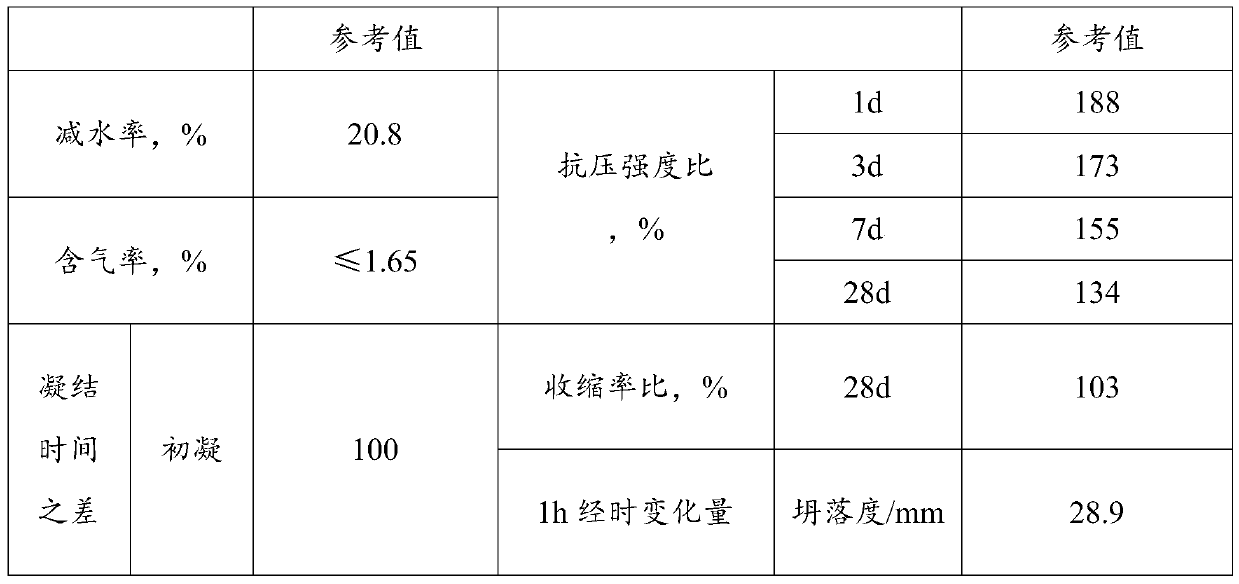

Embodiment 3

[0039] An anti-rust and high-slump polycarboxylate high-performance water reducer is processed from the following raw materials in parts by weight:

[0040] 390 parts of methallyl alcohol polyoxyethylene ether, 3.75 parts of hydrogen peroxide, 2.125 parts of mercaptopropionic acid, 0.875 parts of vitamin C, 38.5 parts of acrylic acid, 16.5 parts of caustic soda, 1-ethyl-(3-dimethylaminopropyl ) 15 parts of carbodiimide hydrochloride, 6 parts of dimethylacetamide, 10 parts of β-glucan, 8 parts of water-based rust inhibitor, and 325 parts of water.

[0041] The preparation method of embodiment 3, described method step is as follows:

[0042] Step S1: Put methallyl alcohol polyoxyethylene ether and part of the formula amount of water into the reactor, and heat up to 40±2°C for later use;

[0043] Step S2: adding hydrogen peroxide to the material in step S1, and reacting for a period of time;

[0044] Step S3: Using the remaining amount of water, configure mercaptopropionic acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com