Monodisperse polymer microsphere for dry spraying machine

A polymer, monodisperse technology, applied in the field of materials, can solve the problems of uneven box thickness, uneven background color, black spots, etc., and achieve the effect of preventing storage agglomeration, low water content, and low water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

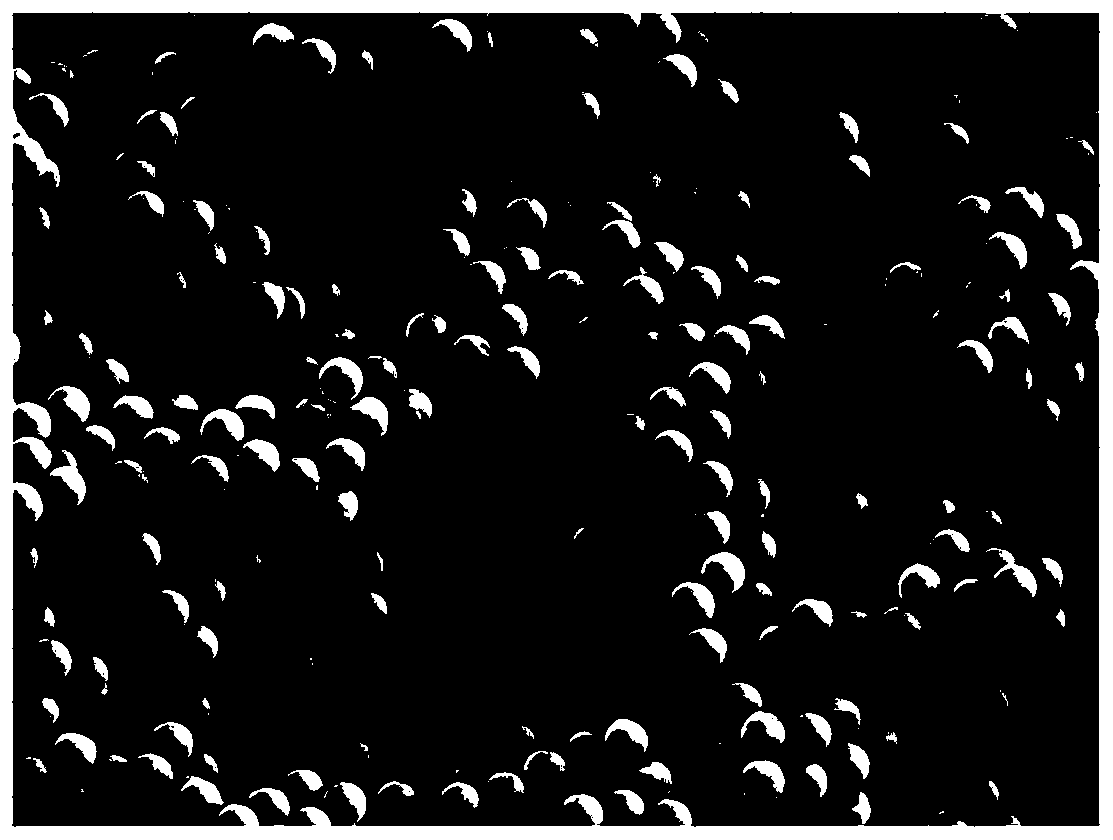

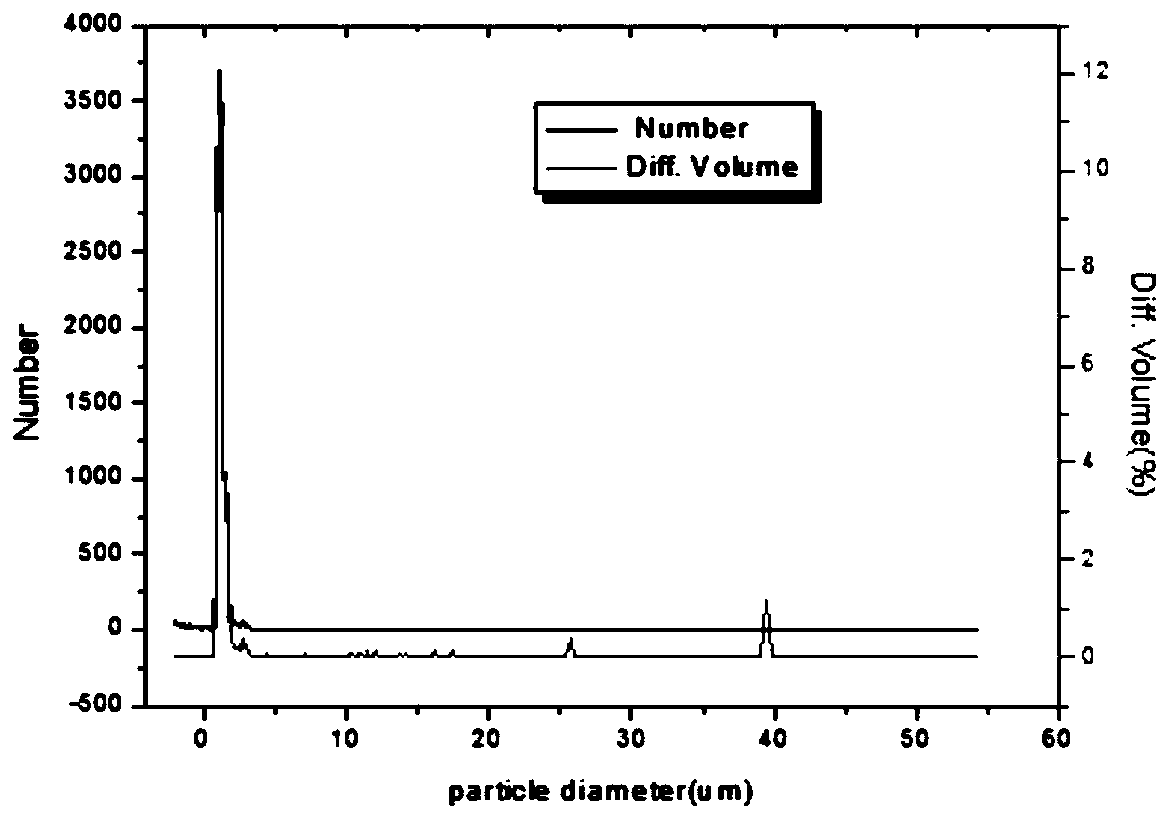

[0041] (1) Preparation of seed microsphere emulsion: 0.12g of sodium chloride (chemically pure, China Pharmaceutical Group Shanghai Chemical Reagent Company), 15g of deblocked styrene (chemically pure, American Sigma-Aldrich Company), 100mL of deionized water (self-made) and 75mL of 0.002g / mL of refined potassium persulfate (chemically pure, Sigma-Aldrich, USA) solution were ultrasonically dispersed in a closed reaction kettle, ultrasonically and stirred for 30min under nitrogen protection, and then heated to 70°C for constant temperature polymerization for 18h , and then repeatedly centrifuged and washed the obtained particles with deionized water several times to obtain the seed polymer microspheres, and finally redispersed the above seed microspheres into deionized water, and blown nitrogen gas for 30 minutes to remove the residual styrene monomer, A bulb emulsion of 1.22 μm can be obtained.

[0042] The surface of the seed microspheres prepared by this method is smooth, wi...

Embodiment 2

[0051] (1) Preparation of seed microsphere emulsion: Ultrasonic dispersion of the refined potassium persulfate solution of 0.14g of sodium chloride, 20g of dehindered styrene, 150mL of deionized water and 100mL of 0.002g / mL in a closed reaction kettle, Ultrasound and stirring for 30 minutes under the protection of nitrogen, then the temperature was raised to 70°C for constant temperature polymerization for 18 hours, and then the obtained particles were repeatedly centrifuged and washed with deionized water for several times to obtain seed polymer microspheres, and finally the above seed microspheres were redispersed in the deionized In deionized water, nitrogen gas was blown in for 30 minutes to remove residual styrene monomer, and a bulb emulsion of 1.90 μm was obtained.

[0052] (2) Preparation of monodisperse polymer microspheres: Weigh 30 g of 0.25% sodium dodecylbenzenesulfonate aqueous solution and 0.6 times of seed liquid dibutyl phthalate to ultrasonically disperse them...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| coefficient of variation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com