Aqueous dispersion of polyurethane or polyurethane urea as well as preparation method and application of aqueous dispersion

A technology of polyurethane urea and dispersion, which is applied in the direction of textiles and papermaking, and can solve problems such as the decline in water resistance of the coating and the inability to meet the use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

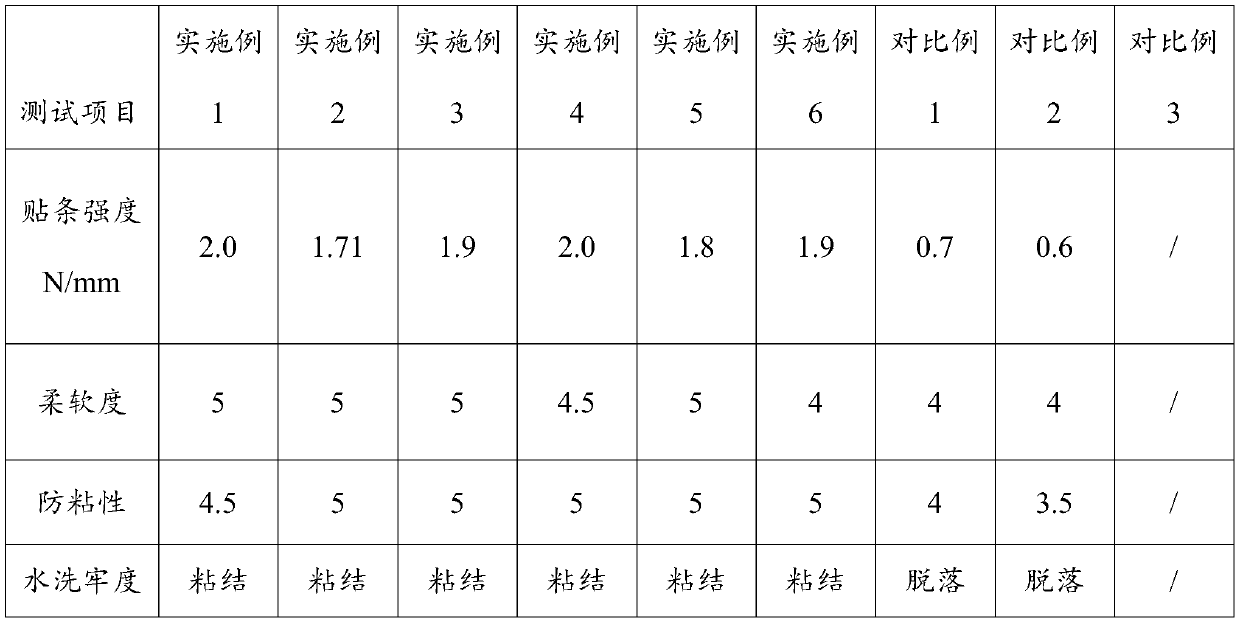

Embodiment 1

[0132] 1) Add 210g of dehydrated PNA2000, 84g of CMB54, 5.88g of MPEG-1200, 10g of 12-hydroxystearic acid, 0.1g of bismuth neodecanoate, 47.6g of hexamethylene diisocyanate and 35.7g of acetone into a In a 1L four-necked round-bottomed flask with nitrogen inlet and outlet, the reaction was carried out with stirring at 70-80°C until the NCO content in the reaction system reached 2.50wt%, and the reaction was terminated to obtain the isocyanate-terminated prepolymer I;

[0133] 2) Add 528g of acetone to the system for dilution, lower the temperature and keep the temperature of the system at 43-50°C, add 4.9g of A95, 13.5g of isophoronediamine and 1.4g of AMP-95 for chain extension reaction for 15min to obtain terminal Isocyanate prepolymer II; then add 625g of water under high-speed stirring to disperse the obtained reaction product, and add 0.8g of ethylenediamine after the dispersion and continue stirring for 5min. After separation of acetone by distillation, an aqueous disper...

Embodiment 2

[0135] 1) 210g of dehydrated PNA2000, 84g of CMB54, 5.88g of MPEG-1200, 1.9g of 2-hydroxystearic acid, 0.1g of bismuth neodecanoate, 47.6g of hexamethylene diisocyanate and 137.4g of acetone were added to In a 1L four-neck round-bottomed flask equipped with a nitrogen inlet and outlet, the reaction was carried out with stirring at 70-80°C until the NCO content in the reaction system reached 2.33wt%, and the reaction was terminated to obtain the isocyanate-terminated prepolymer I;

[0136] 2) Add 1122g of acetone to the system for dilution, lower the temperature and keep the system temperature at 43-50°C, add 19g of A95 and 11.5g of AMP-95 for chain extension reaction for 15min to obtain isocyanate-terminated prepolymer II; then The resulting reaction product was dispersed by adding 625 g of water with stirring. After separation of acetone by distillation, the aqueous dispersion of solvent-free polyurethane or polyurethane urea is obtained, its theoretical design molecular weig...

Embodiment 3

[0138] 1) 210g of dehydrated PNA2000, 84g of CMB54, 20g of MPEG-1200, 20g of 12-hydroxystearic acid, 0.1g of bismuth neodecanoate, 47.6g of hexamethylene diisocyanate and 7.6g of acetone were added to the In a 1L four-neck round-bottomed flask at the import and export, the reaction was carried out with stirring at 70-80°C until the NCO content in the reaction system reached 2.04wt%, and the reaction was terminated to obtain the isocyanate-terminated prepolymer I;

[0139] 2) Add 236.4g of acetone to the system for dilution, lower the temperature and keep the system temperature at 43-50°C, add 2g of A95, 10g of isophoronediamine and 0.4g of AMP-95 for chain extension reaction for 15min to obtain terminal isocyanate the prepolymer II; the resulting reaction product was then dispersed by adding 625 g of water under high-speed stirring. After acetone is separated by distillation, the aqueous dispersion of solvent-free polyurethane or polyurethane urea is obtained, its theoretical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com