A current collector provided with a micro-insurance and a lithium-ion battery pole piece containing the current collector

A current collector and microstructure technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve problems such as low electrical and thermal conductivity, low internal resistance, reduced electrical conductivity of current collectors, and discounts on electrical conductivity, and achieve good The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] First, the aluminum foil with a thickness of 10 μm is roughened, and the roughening treatment steps are:

[0045] (1) Surface cleaning: Clean the aluminum foil with ultrasonic vibration in ethanol, then soak it in 0.05mol / L lye for 3 hours; finally clean it with water;

[0046] (2) Electrochemical oxidation: The cleaned aluminum foil is electrochemically oxidized in 0.5mol / L oxalic acid solution for 5min, and its current density is 10mA / cm 2 ;

[0047] (3) Drying treatment: the treated aluminum foil is washed with deionized water and then dried.

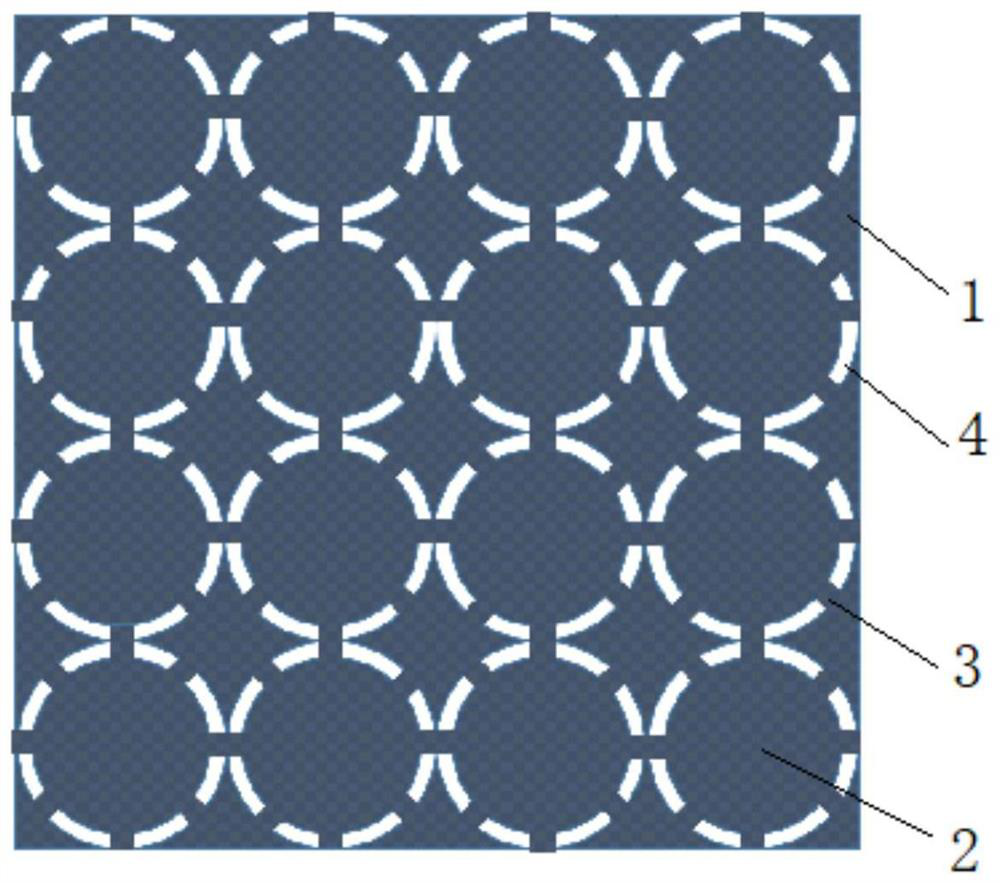

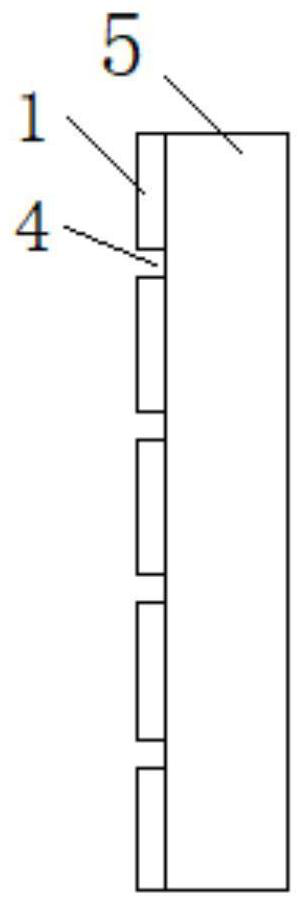

[0048]Then, a conductive aluminum coating 1 is coated on the surface of the roughened aluminum foil by vacuum evaporation, and the thickness of the conductive aluminum coating is 100 nm. The conductive aluminum coating 1 includes microstructure units 2 and contact points 3 evenly arranged on the aluminum foil; an isolation region 4 is formed between adjacent microstructure units 2, and the contact point 3 is arranged on the ...

Embodiment 2

[0051] Copper foil with a thickness of 6 μm is roughened first, and the roughening treatment steps are:

[0052] (1) Surface cleaning: ultrasonically clean the copper foil in ethanol, then soak it in 0.08mol / L lye for 2 hours; finally clean it with water;

[0053] (2) Electrochemical oxidation: electrochemically oxidize the cleaned copper foil in 0.5mol / L citric acid solution for 5min, and the current density is 15mA / cm2;

[0054] (3) Drying treatment: the treated copper foil is washed with deionized water and then dried.

[0055] The structure of the current collector is the same as in Example 1, the only difference is that a conductive copper coating is vacuum-evaporated on the copper foil substrate after roughening treatment, the thickness is 200nm, and the total area of the eight contact points is the area of the circular microstructure unit 10% of that; 15,000 microstructure units are provided per square meter of the surface of the copper foil substrate.

[0056] Th...

Embodiment 3

[0058] First, the aluminum foil with a thickness of 10 μm is roughened, and the roughening treatment steps are:

[0059] (1) Surface cleaning: Clean the aluminum foil with ultrasonic vibration in acetone, then soak it in 0.5mol / L lye for 0.5h; finally clean it with water;

[0060] (2) Electrochemical oxidation: The cleaned aluminum foil is electrochemically oxidized in 0.05mol / L oxalic acid solution for 20min, and the current density is 50mA / cm2;

[0061] (3) Drying treatment: the treated aluminum foil is washed with deionized water and then dried.

[0062] Then, on the surface of the aluminum foil 5, a conductive aluminum coating 1 (such as figure 2 , 3 Shown), the thickness of the conductive aluminum coating 1 is 300nm. The conductive aluminum coating 1 includes microstructure units 2 and contact points 3 uniformly arranged on the aluminum foil 5; isolation regions 4 are formed between adjacent microstructure units 2, and the contact points 3 are arranged on the isolatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com