All-weather solar evaporative water purifier and preparation method and application thereof

A solar energy, all-weather technology, applied in chemical instruments and methods, seawater treatment, water/sewage treatment, etc., can solve the problems of complex production of distillers, inability to expand scale, low work efficiency, etc., and achieve good water capture capacity, good Evaporation performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

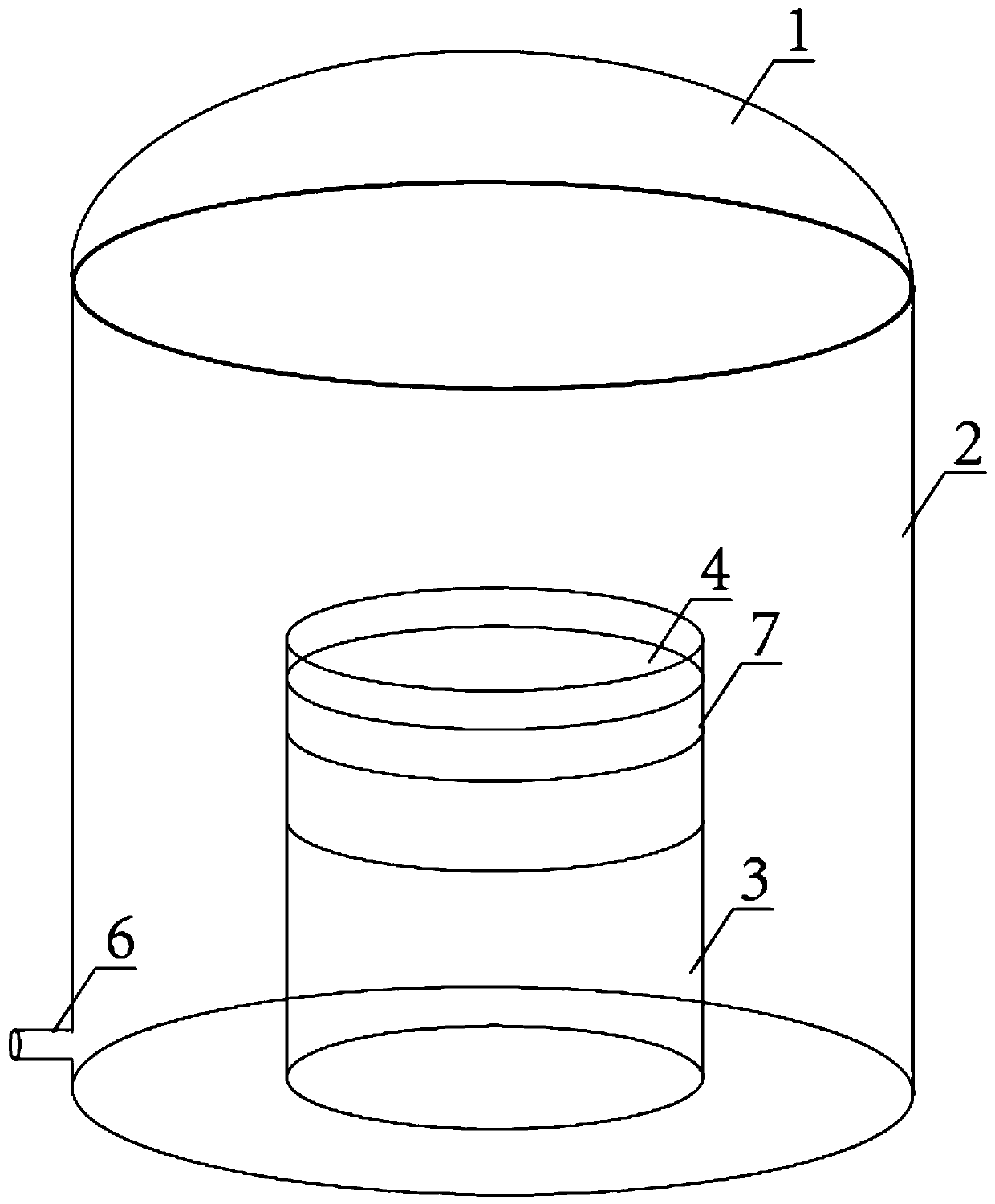

[0025] Add 1.25g of ferric chloride into 50mL of absolute ethanol to obtain a brown ferric chloride solution (25mg / mL); dissolve 2g of pyrrole monomer in 78mL of absolute ethanol to obtain a pyrrole solution; product, see figure 2 , cut into a cylindrical structure when used, with an outer diameter of 80mm and a height of 30mm), soaked in ferric chloride solution (the thickness of the soaked part is 20% of the total thickness of the sponge), soaked for 5 minutes, took out the sponge and put it in a vacuum drying oven for 80 After drying at ℃ for 90 minutes, take it out, drop all the pyrrole solution on the part of the sponge soaked in ferric chloride, and put it in a vacuum drying oven again to dry at 105 ℃ for one hour; then take out the sponge, and soak the part of ferric chloride 7 ( figure 1 Middle) has turned black, and the other parts have not changed color, which is a porous water-absorbing material.

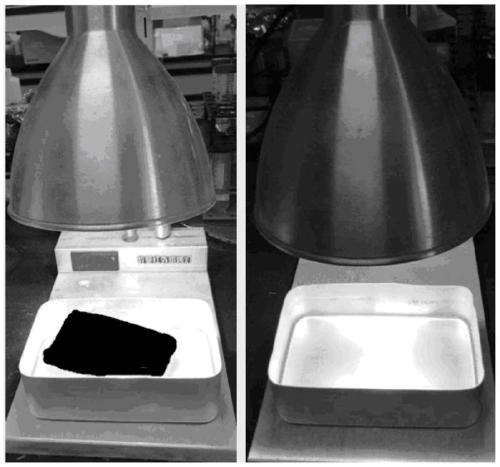

[0026] Two containers of the same size, A and B, were prepared. On...

Embodiment 2

[0029] Add 1.25g of ferric chloride to 50mL of absolute ethanol to obtain a brown ferric chloride solution (25mg / mL), and cut the sponge (melamine sponge, a commercially available product) into a cylindrical structure (outer diameter 80mm, height 30mm) ,See figure 2 , the same as the sponge in Example 1) soaked in ferric chloride solution (the thickness of the soaked part is 20% of the total thickness of the sponge), soaked for five minutes, took out the sponge and put it in a vacuum drying oven at 80°C for 90 minutes and then took it out , at this time the ethanol is completely volatilized; then put 5ml of pyrrole into the vacuum drying oven and keep the temperature at 80°C. The high temperature of the drying oven makes the pyrrole evaporate, and the pyrrole vapor will treat the whole sponge. Take out the sponge after 1 hour, and the sponge is treated with ferric chloride The treated part becomes black (MPF part), while the untreated part remains white in color (MF part, whi...

Embodiment 3

[0034] Prepare a transparent cover, a treatment chamber, and a sewage chamber according to conventional methods. The opening of the sewage chamber is the sewage inlet, and the conventional method of the treatment chamber is equipped with a clean water outlet pipe (4mm inner diameter, which can be covered with a hose); put porous water-absorbing materials into the sewage chamber. , the part containing polypyrrole faces upward, the sewage chamber is placed in the treatment chamber, and the transparent cover is placed on the treatment chamber to form a seal, so that an all-weather solar evaporation water purifier is obtained.

[0035] Prepare four identical all-weather solar evaporative water purifiers, two of which do not contain porous water-absorbing materials and only have solutions, defined as water purifier A and water purifier B, and two of which contain porous water-absorbing materials, defined as water purifier C , Water purifier D, the simulation demonstration of sewage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com