Asymmetric hydrophilic/hydrophobic composite fiber membrane and preparation method thereof

A technology of composite fiber membrane and hydrophobic polymer, which is applied in the fields of fiber processing, fiber chemical characteristics, chemical instruments and methods, etc., can solve the problem that the amphoteric properties cannot be maintained for a long time, it is difficult to form a large-area membrane, and the mechanical strength of the amphoteric membrane is low. and other problems, to achieve the effect of good water collection performance, strong tolerance, fast and effective water collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] In a preferred embodiment of the present invention, the preparation method specifically includes the following steps:

[0054] Step 1. Pretreat the metal mesh.

[0055] The metal mesh is selected from the metal mesh described in the first aspect of the present invention.

[0056] The pretreatment includes cutting, washing and drying.

[0057] After cutting the metal mesh to the desired size, put it in the cleaning solution for cleaning. In a preferred embodiment of the present invention, the metal mesh is sequentially put into acetone, absolute ethanol and deionized water for ultrasonic cleaning.

[0058] After washing, the metal mesh is dried. In the present invention, the drying method and drying equipment are not specifically limited, as long as the drying purpose can be achieved. For example, in an oven, dry at 50-80°C for 2-3h.

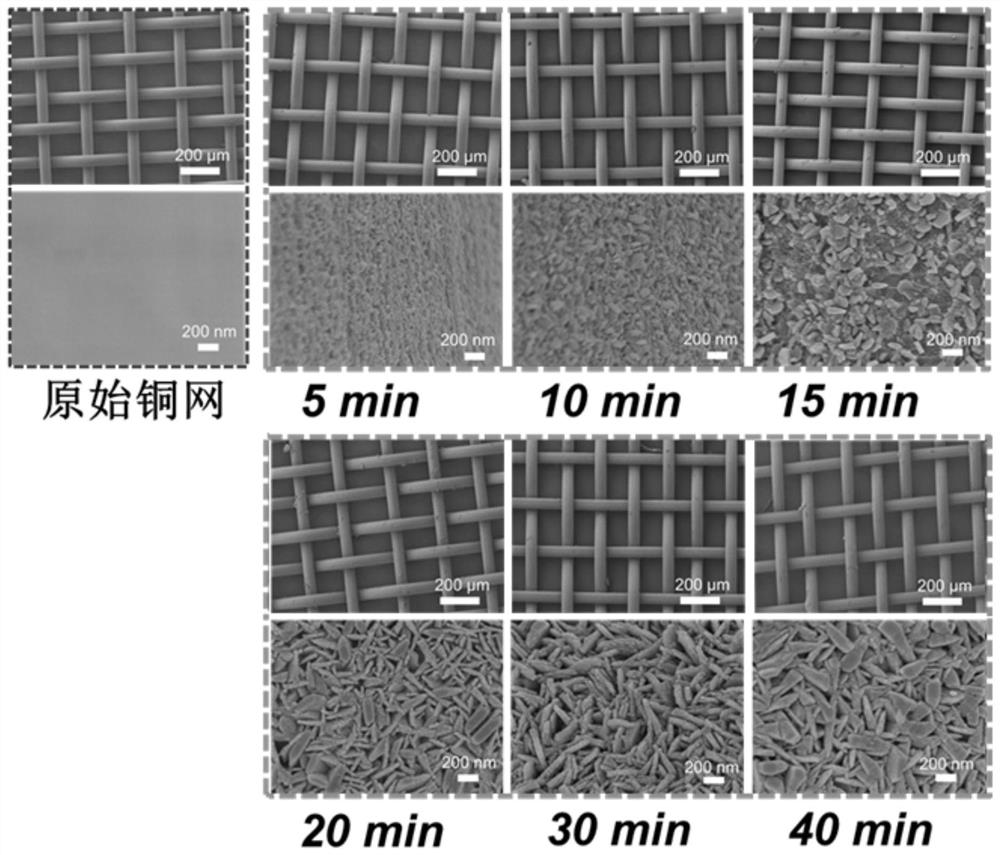

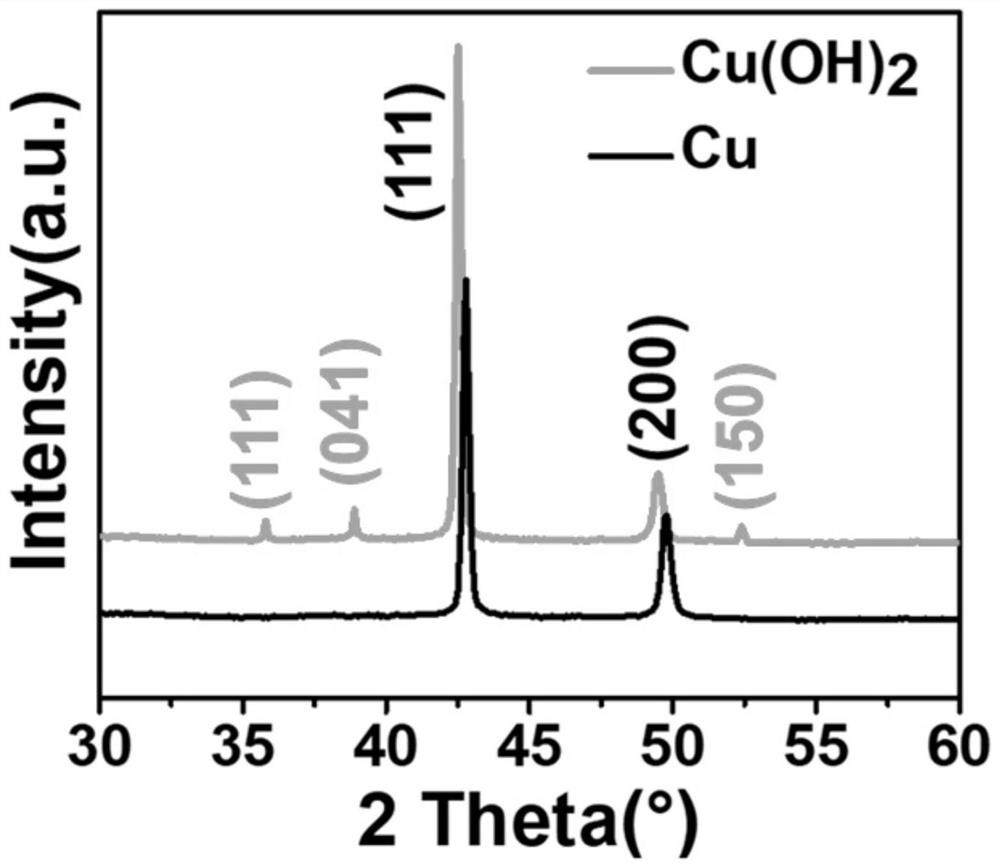

[0059] Step 2, oxidizing the pretreated metal mesh to obtain a metal mesh with a metal hydroxide layer.

[0060] The oxidation trea...

Embodiment 1

[0083] Weigh K 2 S 2 o 8 and NaOH dry powder, put them in two beakers respectively, add 100ml deionized water respectively, and obtain the NaOH solution with the concentration of 2.5mol / L and the K with the concentration of 0.1mol / L respectively 2 S 2 o 8 Solution, seal the beaker containing the solution with parafilm for later use.

[0084] Cut a number of copper meshes with a size of 4cm×4cm, clean the cut copper meshes with acetone, absolute ethanol and deionized water for several minutes in order to remove oil and other pollutants on the surface of the copper meshes, take them out and place them in Dry in an oven at 60°C for 2 hours and take it out for later use.

[0085] Place the pretreated copper mesh in a mixed solution of 2.5mol / L sodium hydroxide solution and 0.1mol / L potassium persulfate solution (the volume ratio of the two solutions is 1:1, stir until evenly mixed ), after the seal is intact, place it on a magnetic stirrer, and soak for a certain period of t...

Embodiment 2

[0090] Add poly(vinylidene fluoride-hexafluoropropylene) (PVDF-HFP) and 1H,1H,2H,2H-perfluorodecyltrimethoxysilane (fluorosilane, F) to DMF (N,N-dimethyl A mixed solvent of formamide) and acetone (wherein the mass ratio of DMF to acetone is 7:3, and the mass ratio of PVDF-HFP to fluorosilane is 10:1), and the container containing the mixed solution is sealed with a parafilm. Stir vigorously at 40°C for 6 hours to completely dissolve the PVDF-HFP particles and form a transparent and uniform PVDF-HFP / F spinning solution.

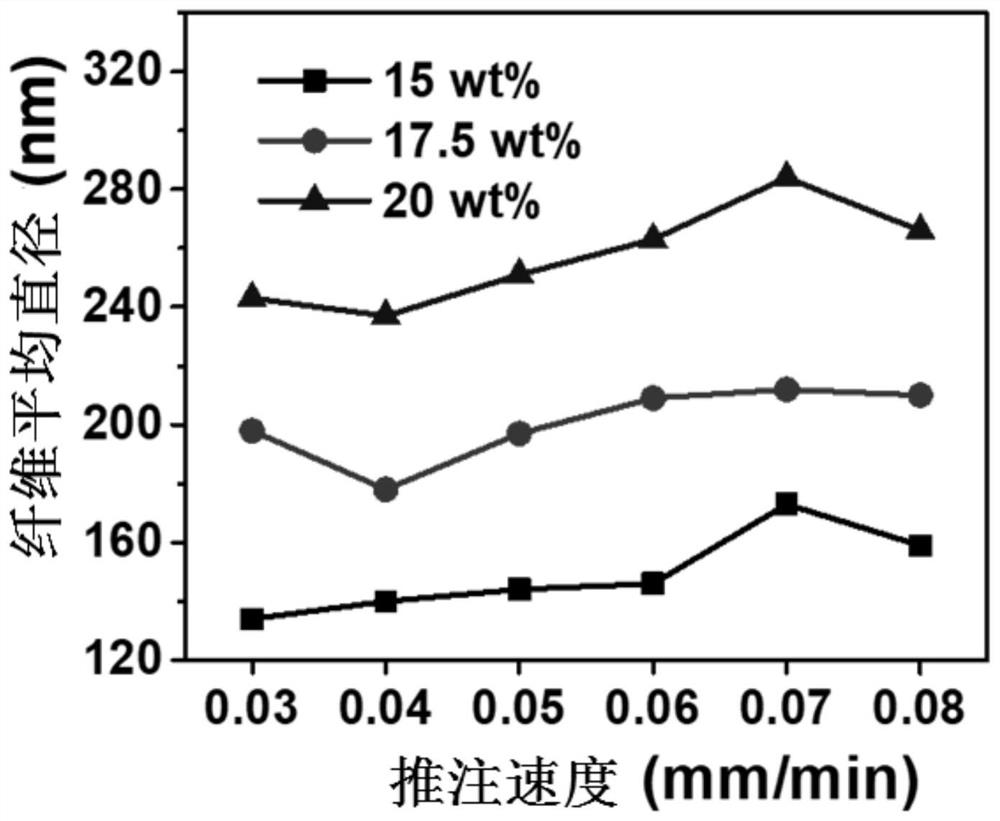

[0091] Spinning solutions with mass fractions of PVDF-HFP of 15wt%, 17.5wt% and 20wt% were respectively prepared by the above method for use in subsequent experiments.

[0092] Draw 3mL of PVDF-HFP / F homogeneous solution with a plastic dropper, place it in a 5mL syringe, then select a spinneret with an inner diameter of 0.6mm, connect it to the high-voltage power supply of the spinning equipment, and perform electrospinning . During the spinning process, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com