Corrosion-resistant self-adhesive low-smoke halogen-free fireproof wrapping tape material and preparation method thereof

A self-adhesive and corrosion-resistant technology, which is applied in the field of corrosion-resistant self-adhesive low-smoke and halogen-free fireproof wrapping tape materials and its preparation, can solve the problems of stringent environmental protection requirements, failure to meet, and pollute the environment, and achieve improved fire and flame retardancy High performance, barrier heat transfer, low calorific value of combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

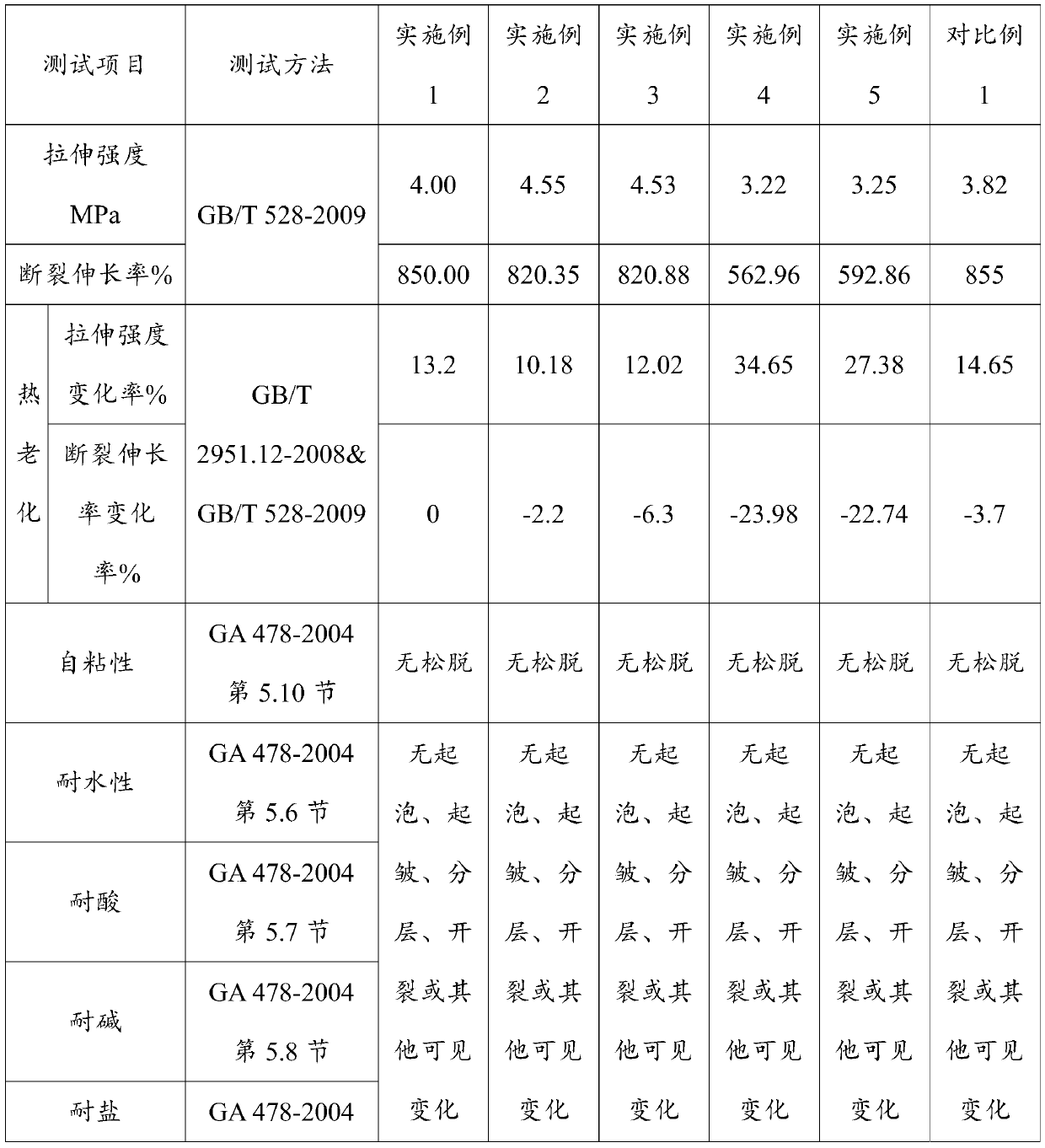

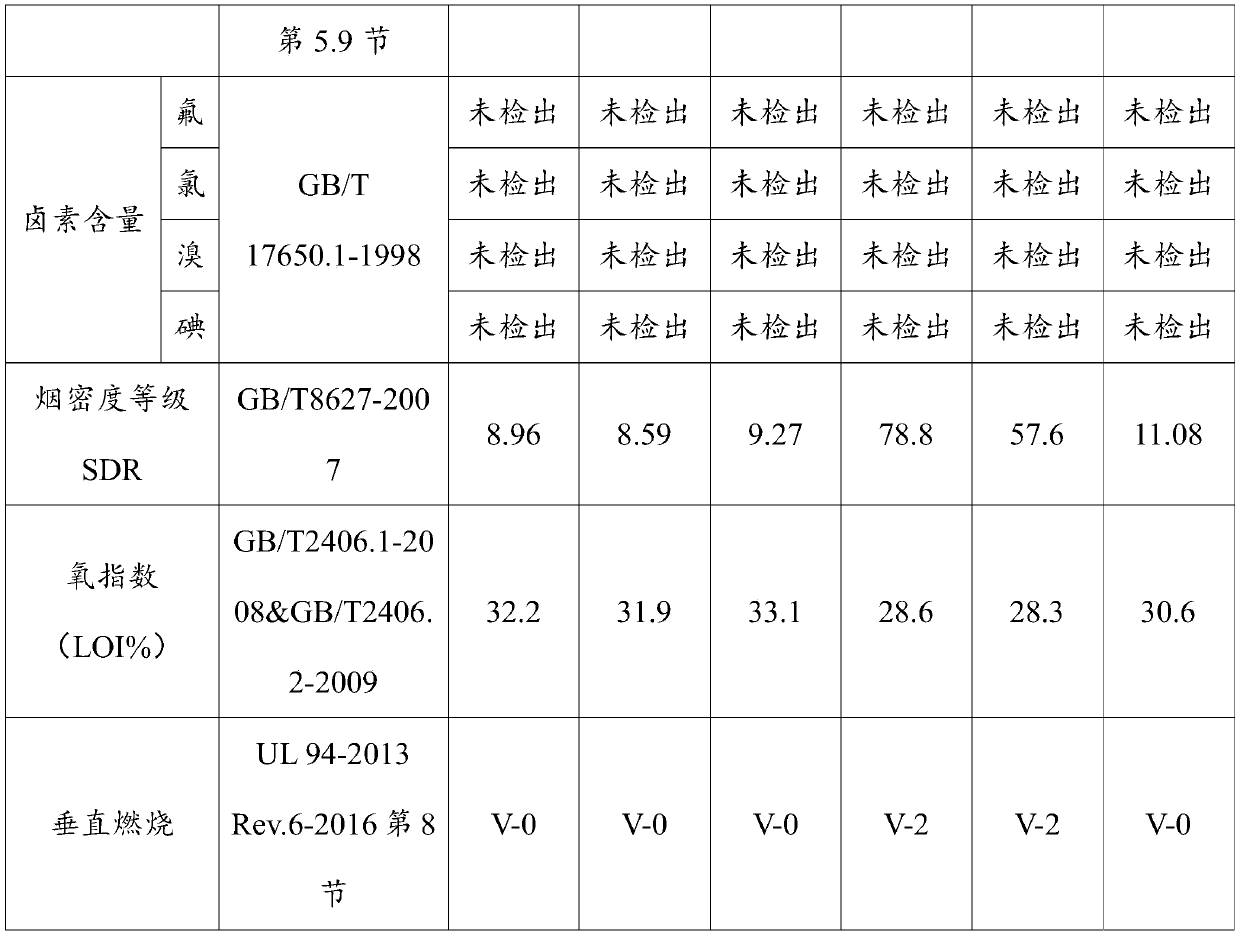

Examples

Embodiment 1

[0023] (1) 100 parts of methyl vinyl silicone rubber raw rubber (molecular weight 650,000, vinyl content 1.5%), 25 parts of fumed white carbon black (particle size 12nm, purity 95% or more, BET specific surface area is 200m 2 / g), 3 parts of organically modified montmorillonite (1250 mesh), 3 parts of hydroxy silicone oil, pre-mixed with an internal mixer, and discharged below 70℃;

[0024] (2) Put the rubber mixture of step (1) into the kneader, add 40 parts of ammonium polyphosphate and 10 parts of pentaerythritol that have been pre-baked, close the top of the kneader, turn on the kneader and mix for 15 minutes. After the main machine completely stops rotating, turn on the kneader for reverse mixing for 2 minutes, then forward for 15 minutes, and then reverse for 2 minutes, stop the main machine; open the top cover and let it cool for 10 minutes;

[0025] (3) Add 3 parts of n-butyl borate and continue mixing for 15-20 minutes, transfer the evenly mixed materials to the turnover bo...

Embodiment 2

[0029] (1) 100 parts of methyl vinyl silicone rubber raw rubber (molecular weight 650,000, vinyl content 1.5%), 40 parts of fumed white carbon black (particle size 12nm, purity 95% or more, BET specific surface area is 200m 2 / g), 4.5 parts of organically modified montmorillonite (1250 mesh), 4 parts of hydroxy silicone oil, mixed evenly with an internal mixer in advance, and discharged under 70℃;

[0030] (2) Put the rubber mixture of step (1) into the kneader, add 45 parts of ammonium polyphosphate and 11 parts of pentaerythritol that have been pre-baked, close the top of the kneader, turn on the kneader and mix for 15 minutes. After the main machine completely stops rotating, turn on the kneader for reverse mixing for 2 minutes, then forward for 15 minutes, and then reverse for 2 minutes, stop the main machine; open the top cover and let it cool for 10 minutes;

[0031] (3) Add 5 parts of n-butyl borate and continue mixing for 15-20 minutes, transfer the evenly mixed materials to...

Embodiment 3

[0035] Compared with Example 1, the difference is that the nitrogen-phosphorus flame retardant is the same part by weight of melamine polyphosphate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com