Additive composition and method of preparing same

A manufacturing method and composition technology, applied in the field of additive composition and its manufacturing, can solve problems such as poor compatibility, low OH value of composition ratio content, and limited use range, so as to improve reproducibility, reliability, compatibility and plasticity Excellent, durability-improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

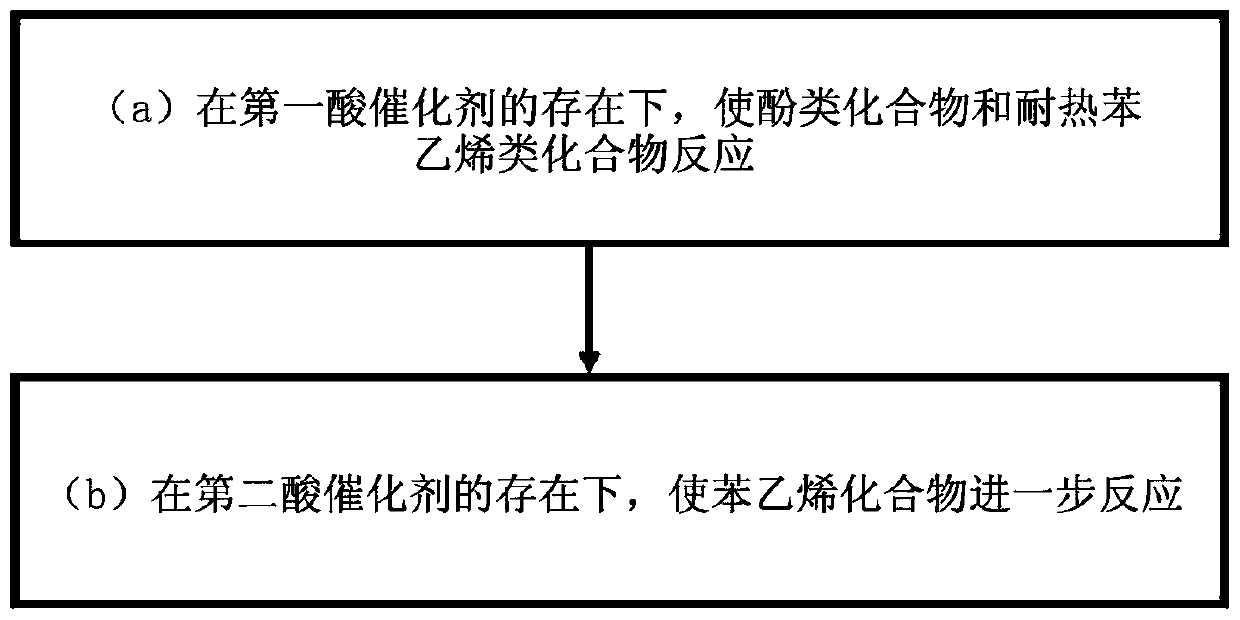

Method used

Image

Examples

Embodiment

[0095] Sulfuric acid catalyst (0.135g, 0.0013eq) was added to phenol (100g, 1eq) and α-methylstyrene (138g, 1.1eq) was added dropwise for 120 minutes until its temperature rose from 70°C to 90°C. After the dropwise addition of α-methylstyrene was completed, the reaction was further performed at the same temperature for 1 hour. Through gas chromatography (Gas chromatography, GC) analysis results, it was confirmed that the mixture of 5.06% tricresyl indane (TMPI) and diphenylmethylpentene (DMP), 63.28% cumylphenol and 25.4% diphenylmethane The ratio of cumylphenol is generated.

[0096] Thereafter, at the same temperature, styrene (66.4 g, 0.6 eq) was further added dropwise for 60 minutes. After the dropwise addition of styrene was completed, the reaction was further performed at the same temperature for 1 hour, thereby obtaining an α-methylstyrenated phenol mixed solution. Sodium bicarbonate (0.116 g, 0.0013 eq) was dissolved in distilled water and added to the resulting solu...

experiment example 1

[0104] The analysis results of the compositions produced according to the above-mentioned Examples and Comparative Examples 1 to 3 are shown in Table 1 below.

[0105] [Table 1]

[0106]

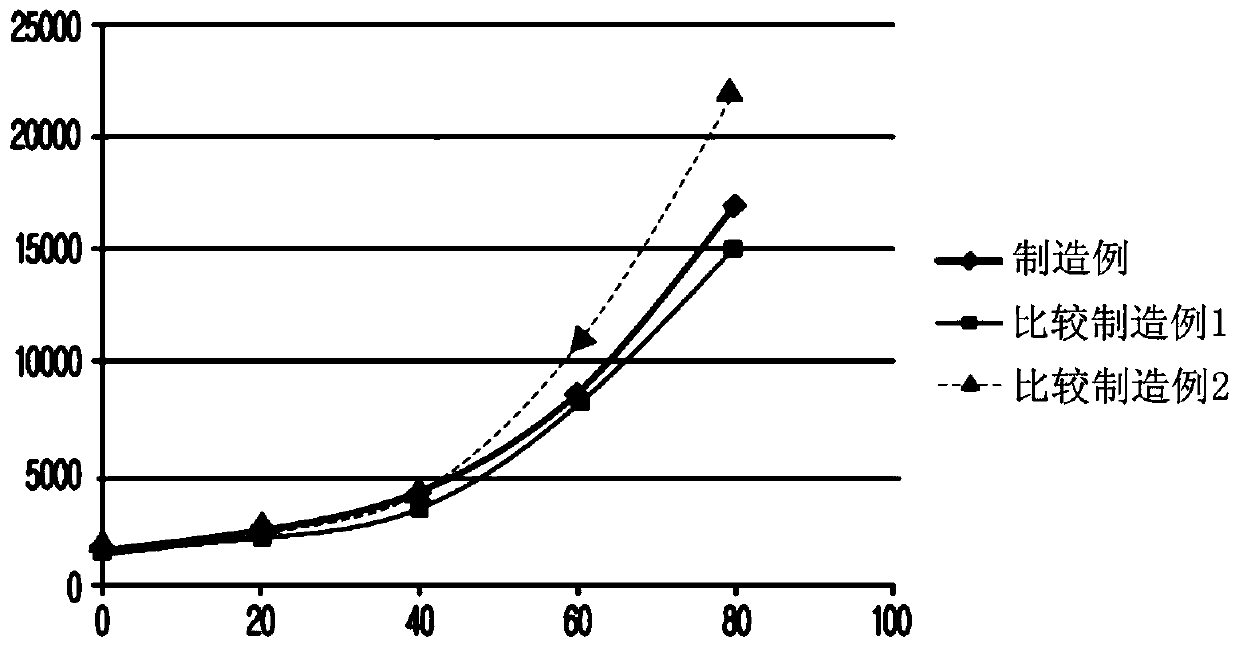

[0107] Production example and comparative production example

[0108] Diluents for epoxy resins require prevention of discoloration and durability, and dodecylphenol has been used as a diluent or modifier for epoxy resins in the past. The epoxy coating composition is a two-component coating divided into a main agent part and a curing agent part, and in this production example, additives are applied to the main agent part.

[0109]In order to compare the α-methyl styrenated phenol composition produced in the above examples with nonylphenol and dodecylphenol which have been conventionally used as diluents for epoxy resins, a main component part was produced. KER-828 of Kumho P&B Chemical Co., Ltd. was used as the epoxy resin, and the specific compounding ratio is shown in Table 2 below....

experiment example 2

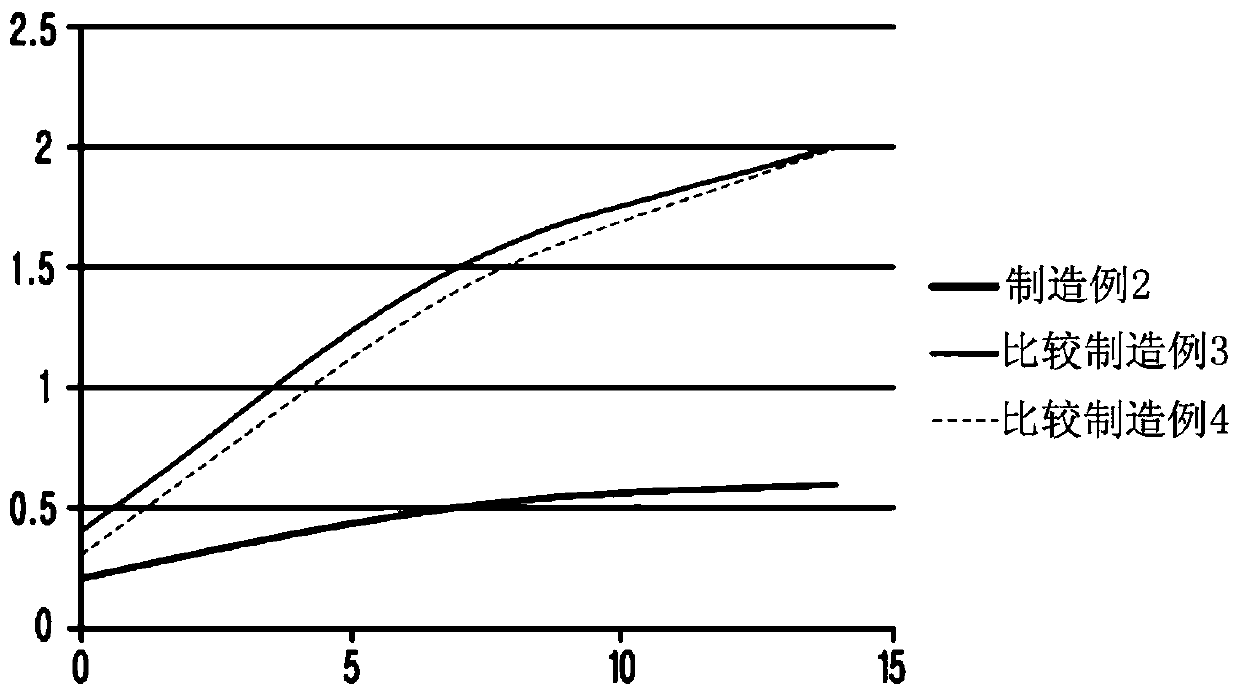

[0123] Experimental example 2: measure the drying time (Drying time) of epoxy coating composition

[0124] In the epoxy coating compositions of the above-mentioned production examples and comparative production examples, the epoxy resin contained in the main agent part and the amine in the curing agent part react when the main agent part and the curing agent part are mixed, thereby passing through the crosslinking reaction ( Crosslinkingreaction) was dried.

[0125] The drying time of the above-mentioned epoxy coating composition was evaluated using the BK-drying time recorder of Elcometer Company, and the results are shown in Table 5 below. The above evaluation was performed by measuring the time taken until the coating film having a thickness of 400 μm at 25° C. was dried.

[0126] [table 5]

[0127]

[0128]

[0129] Referring to Table 5 above, it was confirmed that the curing and drying of Comparative Production Example 1 using conventional dodecylphenol as a dil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com