Bean-based protein adhesive for artificial board and preparation method of bean-based protein adhesive

A protein glue and adhesive technology, used in the preparation of protein adhesives, animal glue or gelatin, adhesives, etc., can solve the problems of high toxicity of cross-linking agents and environmental pollution, and achieve excellent water resistance and bonding strength. High, the effect of solving the problem of formaldehyde release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

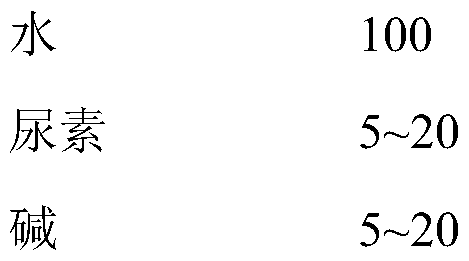

[0046] 1. Prepare materials according to the following weight ratio (Kg):

[0047]

[0048] 1. Put 10Kg of polycarbodiimide, 12Kg of tannic acid and 2Kg of ferric chloride in a reaction kettle, and stir evenly at 800 rpm to obtain a crosslinking agent for soy-based protein adhesives.

[0049] 2. Disperse 5Kg of sodium hydroxide and 10Kg of urea in water, and stir evenly at a rotating speed of 900 rpm to obtain a mixed solution of sodium hydroxide and urea.

[0050] 3. Disperse the cross-linking agent prepared in step 1 into the above-mentioned mixed solution of sodium hydroxide and urea, and stir evenly at 1000 rpm to obtain a mixed solution of sodium hydroxide and urea dispersed with cross-linking agent .

[0051] 4. Add the above-mentioned mixed solution of alkali and urea containing a cross-linking agent to 25 kg of soy-based protein raw material at a rotational speed of 1000 rpm, and copolymerize at 60° C. to obtain a soy-based protein adhesive.

[0052] The performan...

Embodiment 2

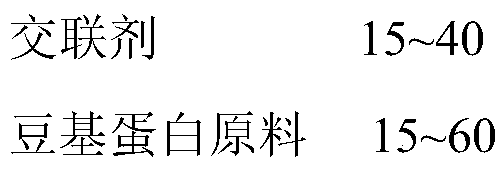

[0056] 1. Prepare materials according to the following weight ratio (Kg):

[0057]

[0058]

[0059] 1. Put 12Kg of polycarbodiimide, 12Kg of caffeic acid and 2Kg of sodium periodate in a reaction kettle, and stir evenly at 1000 rpm to obtain a crosslinking agent for soy-based protein adhesives.

[0060] 2. Disperse 10Kg of potassium hydroxide and 15Kg of urea in water, and stir evenly at a rotating speed of 1100 rpm to obtain a mixed solution of potassium hydroxide and urea.

[0061] 3. Disperse the cross-linking agent prepared in step 1 into the above-mentioned mixed solution of potassium hydroxide and urea, and stir evenly at 1000 rpm to obtain a mixed solution of potassium hydroxide and urea dispersed with the cross-linking agent .

[0062]4. Add the above-mentioned mixed solution of alkali and urea containing a crosslinking agent to 20 kg of soy-based protein raw material at a rotational speed of 1200 rpm, and copolymerize at 70° C. to obtain a soy-based protein ad...

Embodiment 3

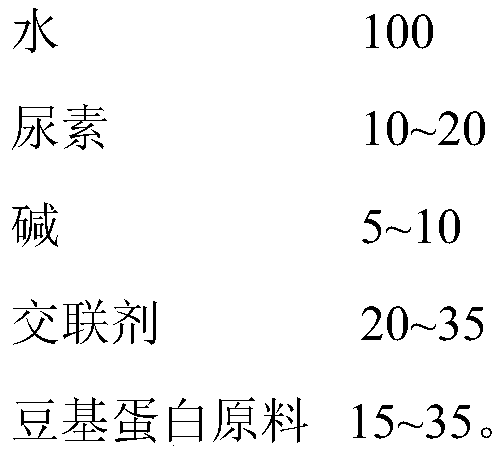

[0067] 1. Prepare materials according to the following weight ratio (Kg):

[0068]

[0069] 1. Put 10Kg of polycarbodiimide, 10Kg of protocatechuic acid and 3Kg of hydrogen peroxide in a reaction kettle, and stir evenly at 1100 rpm to obtain a crosslinking agent for soy-based protein adhesives.

[0070] 2. Disperse 8Kg of calcium hydroxide and 15Kg of urea in water, and stir evenly at a rotating speed of 1000 rpm to obtain a mixed solution of calcium hydroxide and urea.

[0071] 3. Disperse the cross-linking agent prepared in step 1 into the above-mentioned mixed solution of calcium hydroxide and urea, stir evenly at 900 rpm to obtain a mixed solution of calcium hydroxide and urea dispersed with cross-linking agent .

[0072] 4. Add the mixed solution of alkali and urea containing the cross-linking agent to 20 kg of soy-based protein raw material at a rotational speed of 1000 rpm, and copolymerize at 90° C. to obtain a soy-based protein adhesive.

[0073] The performance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com