Archaized door made of aluminum alloy sectional material and preparation method thereof

A technology of aluminum alloy profile and aluminum alloy layer, which is applied in the direction of door leaf, window/door, window/door frame, etc., can solve the problems of poor weather resistance, easy-aging plastics, poor durability, etc., to improve corrosion resistance and fatigue performance, Effects of improving weather resistance and plasticity and reducing quenching sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

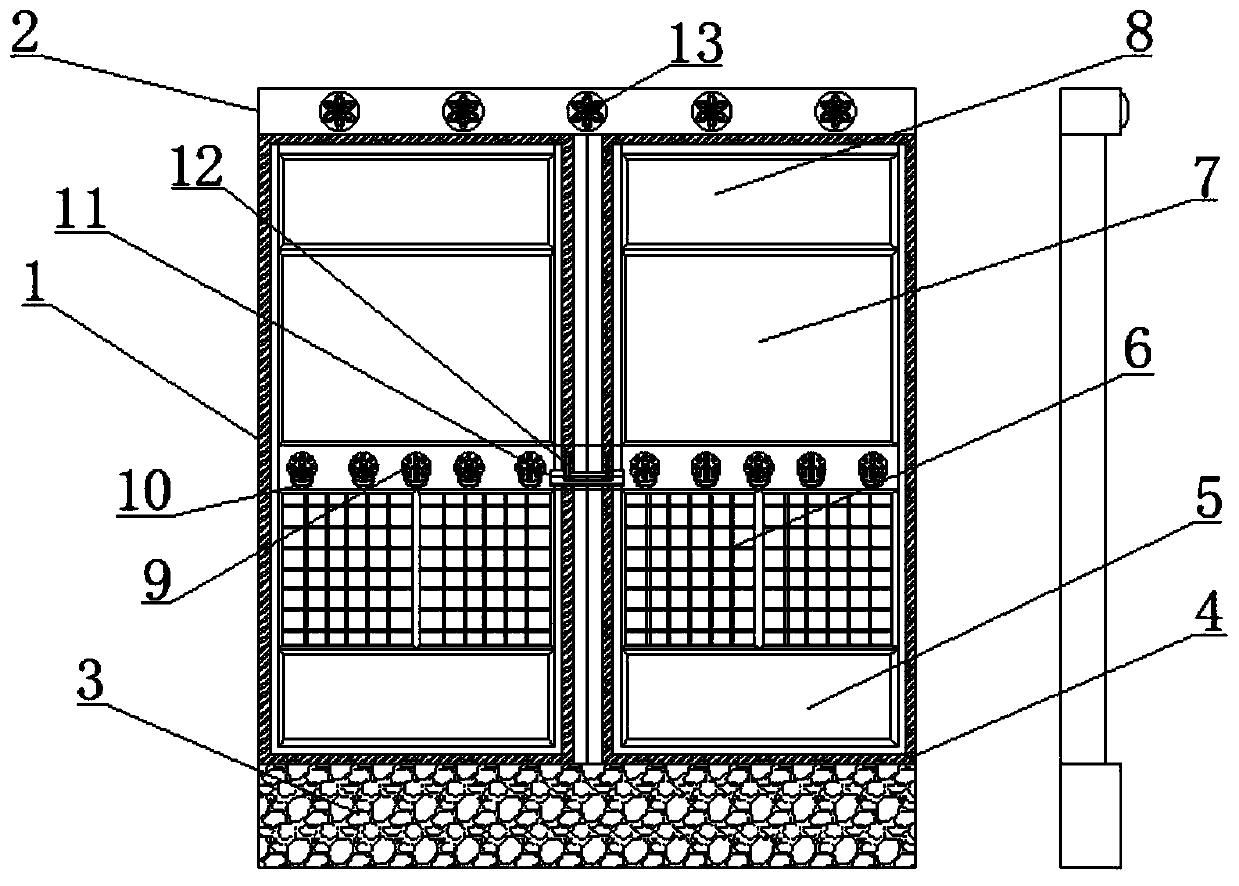

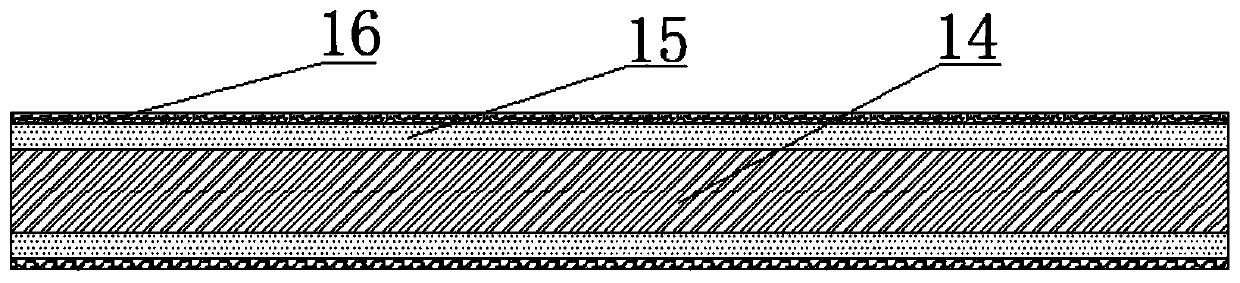

[0034] like Figure 1-2 As shown, an antique door of an aluminum alloy profile, the antique door of the aluminum alloy profile includes an antique door 1, the lower part of the antique door 1 is provided with an antique threshold 3, and the upper part of the antique door 1 is provided with an antique lintel 2; The antique door 1 includes an antique door frame 4, and the inside of the antique door frame 4 is respectively provided with a bottom decorative frame 5, a fence decorative frame 6, an upper decorative frame 7 and a top decorative frame 8, and the bottom decorative frame 5, the upper decorative frame 7 and the top decorative frame There are carved patterns installed in the decorative frame 8; the aluminum alloy profile of the antique door is divided into three layers: the aluminum alloy layer 14 in the middle, the woven carbon fiber layer 15 on both sides of the aluminum alloy layer 14, and the acrylic film on both sides of the woven carbon fiber layer Layer 16.

[003...

Embodiment 2

[0052] The difference between this embodiment and embodiment 2 is:

[0053] The mass percentages of elements in the aluminum alloy layer 14 are: chromium 1%, copper 1%, manganese 2%, zirconium 0.05%, neodymium 0.03%, vanadium 0.04%, germanium 0.5%, silicon 0.5%, nickel 0.1% , titanium 0.05%, iron 1.2%, palladium 0.03%, lanthanum 0.01%, cobalt 0.1%, carbon fiber 1.5%, graphite whisker 0.02%, and the balance is aluminum.

Embodiment 3

[0055] The difference between this embodiment and embodiment 1, 2 is:

[0056] The mass percentages of elements in the aluminum alloy layer 14 are: chromium 1.5%, copper 2%, manganese 2.5%, zirconium 0.1%, neodymium 0.06%, vanadium 0.06%, germanium 0.7%, silicon 0.6%, nickel 0.2% , titanium 0.07%, iron 2.1%, palladium 0.04%, lanthanum 0.02%, cobalt 0.3%, carbon fiber 2.5%, graphite whisker 0.03%, and the balance is aluminum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com