Method for separating 5-methyltetrahydrofolate and improving stability, and used wall material

A methyltetrahydrofolate and stability technology, which is applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas. It can solve the problems of slow separation speed and light influence, and achieve good results. Excellent effects of protection, bioavailability improvement, and embedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1, a kind of method for isolating 5-methyltetrahydrofolate from Lactobacillus sake fermented liquid, carries out following steps successively:

[0053] 1), the preparation of bacteria slime:

[0054] Get a ring of activated Lactobacillus sake (L-sakei) in MRS liquid medium, 37 ℃ culture 24h; Get the culture solution obtained and inoculate in MRS liquid medium according to the inoculum size of 3% (volume %) at 37 ℃ Cultivate for 24 hours; then centrifuge (rotate at 10,000 rpm for 10 minutes), remove the supernatant, and obtain the sludge;

[0055] MRS liquid medium: peptone 10g, yeast powder 5g, glucose 20g, beef extract 10g, sodium acetate 5g, dipotassium hydrogen phosphate 2g, diamine hydrogen citrate 2g, Tween-80 1mL, magnesium sulfate 0.58g, manganese sulfate 0.25g , pH7.0, dilute to 1L with deionized water. Autoclave, 121°C, 15min.

[0056] Preparation of MRS solid medium: add 2% agar on the basis of MRS liquid medium; namely:

[0057] Peptone 10g, ye...

Embodiment 2

[0075] Embodiment 2, the preparation of glycosylation reaction product (wall material), carries out following steps successively:

[0076] 1), casein and chitosan oligosaccharide (1:1w / w), dissolved in phosphate buffer solution (0.2mol / L, pH8.0), so that the concentration of casein is 2mg / mL;

[0077] About 50ml of the mixed solution was placed on a magnetic stirrer and stirred evenly, and synthesized by a dual-frequency ultrasonic microwave ultraviolet combined catalytic synthesizer; ultrasonic power 300w, microwave power 450w, time 20min, temperature 100°C.

[0078] The degree of grafting of casein is 26.21%. The detection method of the degree of grafting is in accordance with the conventional OPA detection method.

[0079] 2), the obtained product is put into a dialysis bag (Mr=8,000~14,000D), and dialyzed in deionized water for (24±2)h to remove unbound product, and the dialysate (deionized water) is changed every 12h, and the Freeze-dry the retentate in the dialysis bag...

Embodiment 3

[0110] Embodiment 3, the method for improving the stability of 5-methyltetrahydrofolate, comprises the following steps:

[0111] The glycosylation reaction product (obtained in Example 2) was dissolved in 0.2 mol / L phosphate buffer solution (pH=7), the concentration of the glycosylation product was 1 mg / mL, and it was placed on a magnetic stirrer for stirring Evenly, then filter, take 4mL from the filtrate and place it in a 5mL sample bottle, then add 100μg of 5-methyltetrahydrofolate, 2 Under the protection of 25°C, seal and avoid light and mix well; get 5-methyltetrahydrofolate microcapsules.

[0112] The embedding rate of casein glycosylation complex on 5-methyltetrahydrofolate reached 75.29%.

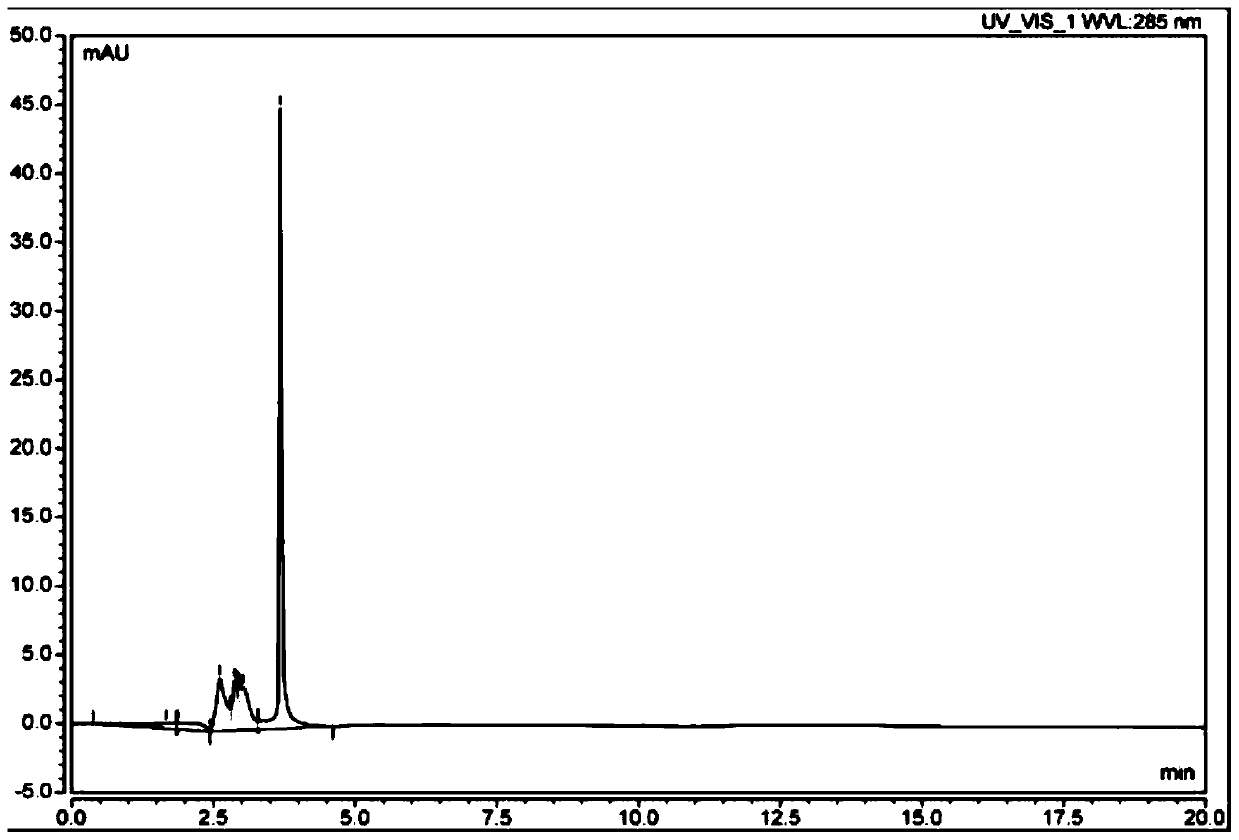

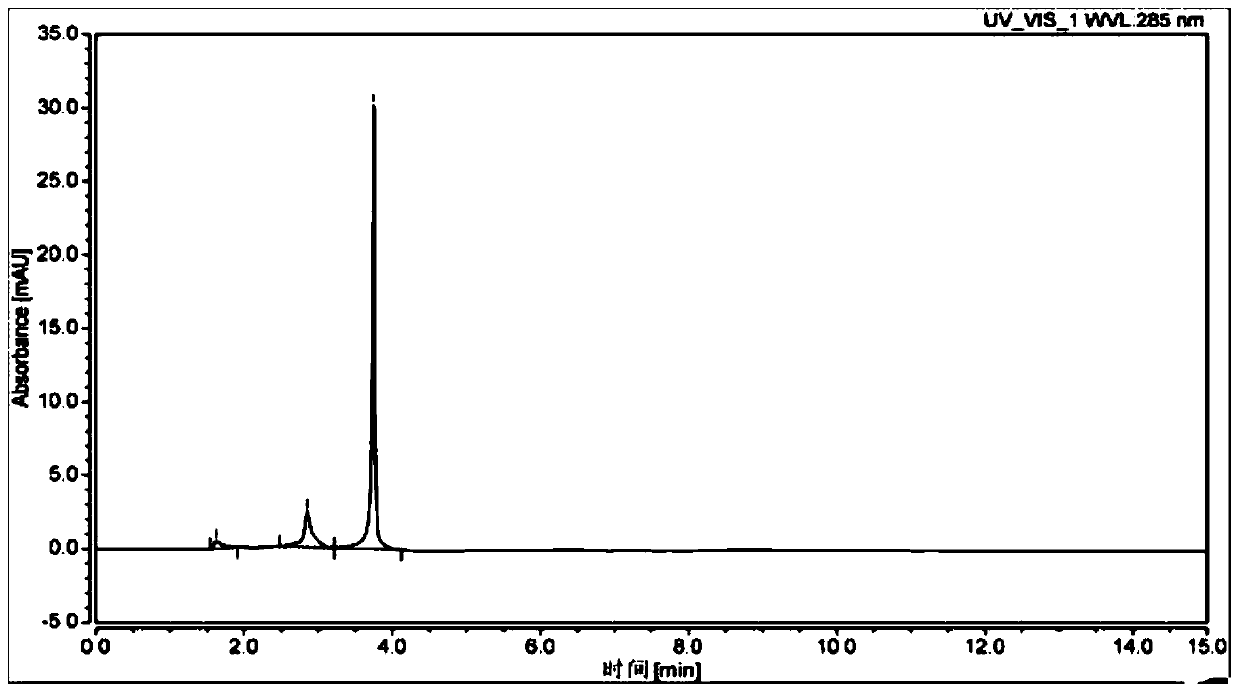

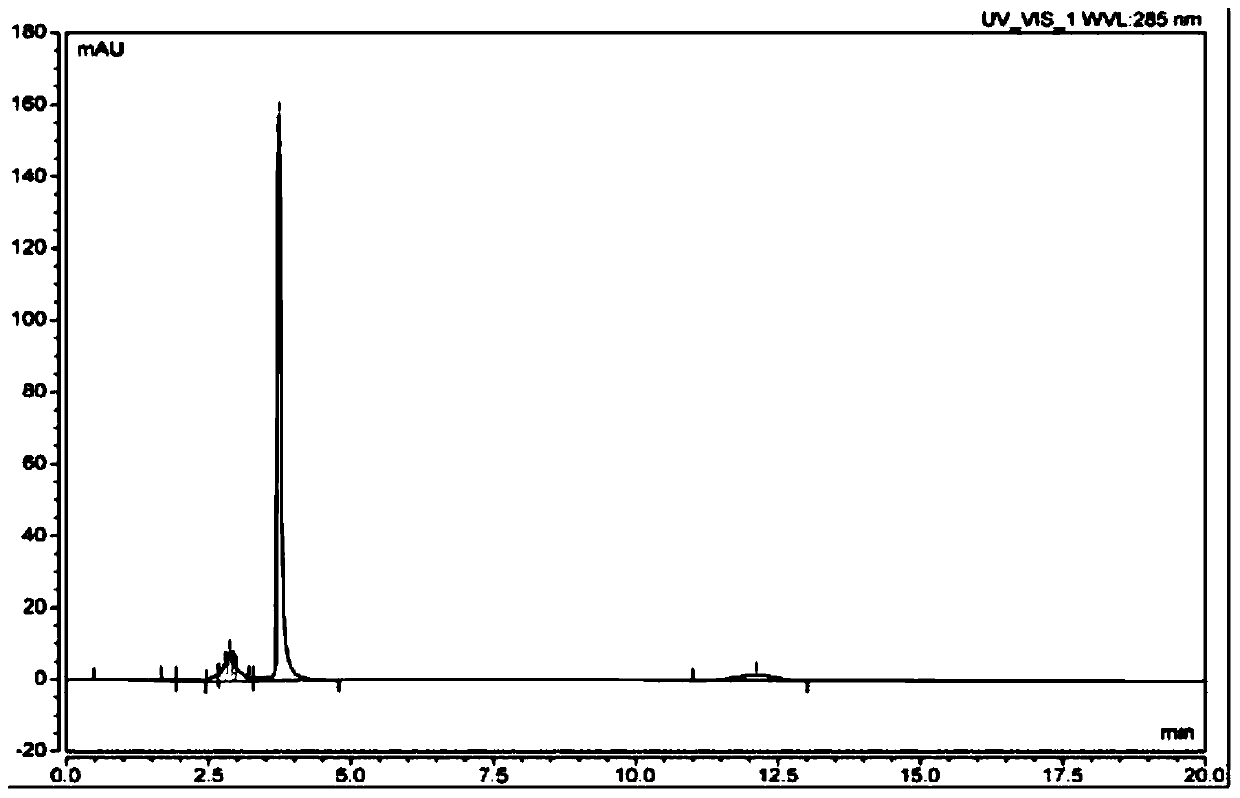

[0113]

[0114] Comparative Example 3-1. The amount of 5-methyltetrahydrofolate added in Example 3 was changed from 100 μg to 50 μg, 150 μg, 200 μg, and 250 μg respectively, and the rest were the same as in Example 3.

[0115] Carry out the following experiments respectively: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com