A palladium-containing single-atom monolithic catalyst and its preparation method and application

A monolithic catalyst and catalyst technology, applied in chemical instruments and methods, preparation of organic compounds, physical/chemical process catalysts, etc., can solve the problems of low hydrogenation efficiency and poor selectivity, and achieve the dispersion of metal active sites , good selectivity and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0058] Soak a 2cm×2cm×2.5cm melamine-formaldehyde sponge in 30mL of 67mg / L palladium acetylacetonate-methanol solution. Shake on a shaker at low speed for 6 hours. The resulting adsorbed palladium ion sponge was rinsed three times with methanol, and vacuum-dried at 70°C for 24 hours. The obtained dried palladium salt loaded sponge was heat-treated at 800° C. for 0.5 h under nitrogen atmosphere. Through inductively coupled plasma emission spectrometry test, the palladium loading amount in the obtained catalyst is 0.023wt%.

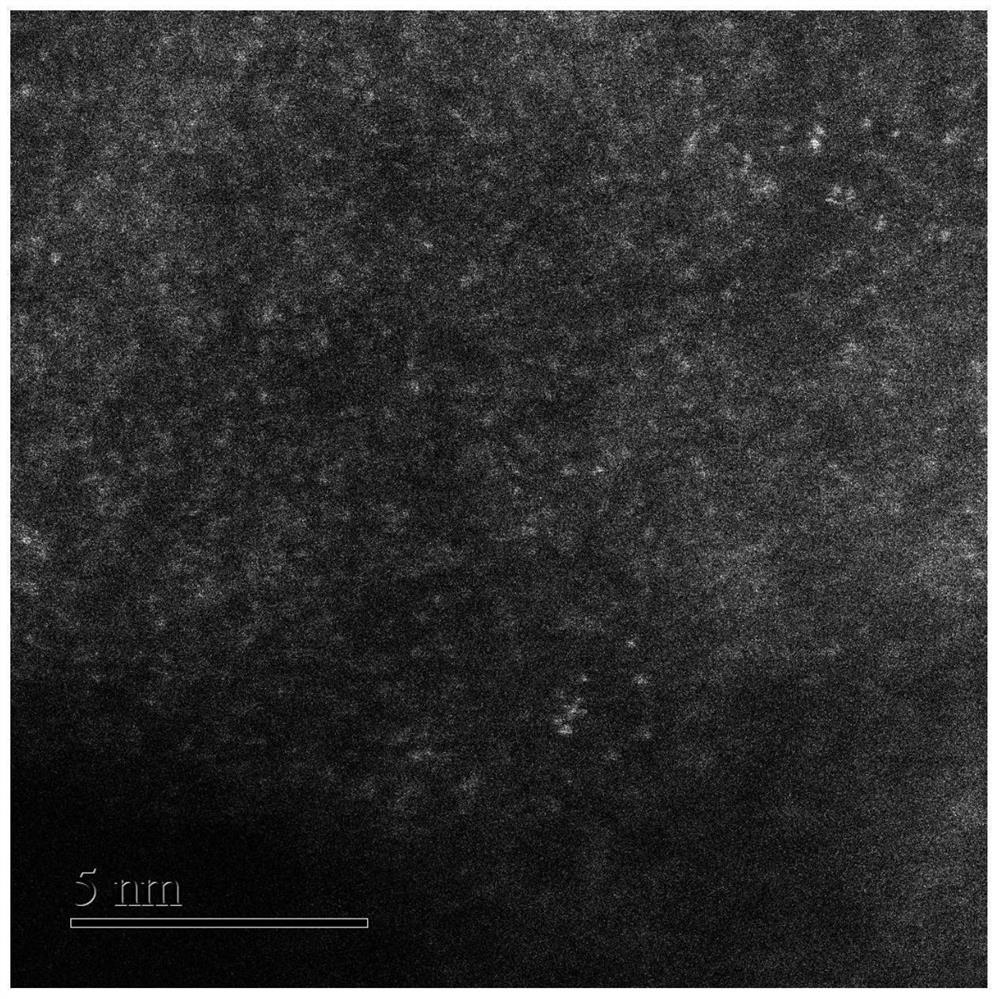

[0059] Gained solid is taken out, and the black solid that obtains is exactly final monatomic palladium-containing catalyst, figure 1 This is the high-angle annular dark-field scanning transmission electron microscope image of the obtained catalyst. The bright spot in the figure is the synthesized single-atom Pd, indicating that the Pd metal atoms are in a monodisperse state on the carbon-nitrogen support, without the formation of clusters or nanoparticle...

preparation example 2

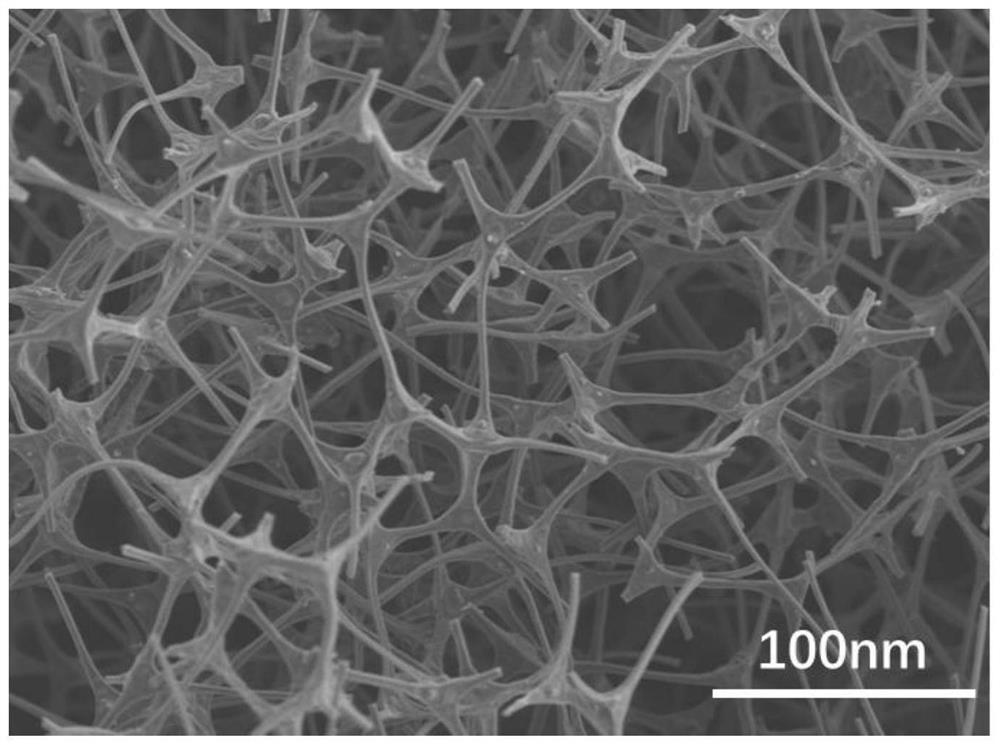

[0063] Other steps and conditions are the same as those in the preparation example, except that the obtained dried palladium salt-loaded sponge is heat-treated at 650° C. for 0.5 h under a nitrogen atmosphere to prepare a palladium-loaded single-atom catalyst. Figure 7 It is an image of the catalyst under a high-resolution scanning electron microscope. It can be seen that the shape of the melamine-formaldehyde sponge is maintained after heat treatment, and a good supporting structure and strength are maintained. The supported amount of palladium in the obtained catalyst was 0.021wt%.

preparation example 3

[0065] The other steps and conditions are the same as those in the preparation example, except that the obtained dried palladium salt-loaded sponge is heat-treated at 900° C. for 0.5 h in a nitrogen atmosphere to prepare a palladium-loaded single-atom catalyst. Figure 8 It is an image of the catalyst under a high-resolution scanning electron microscope. It can be seen that there are some fractures in its structure. Compared with the carbon sponge in the optimal temperature region, the diameter of the carbon-nitrogen frame becomes smaller, and the frame nodes are also damaged, and the structural strength is slightly weaker. . The loading amount of palladium in the obtained catalyst was 0.025wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com