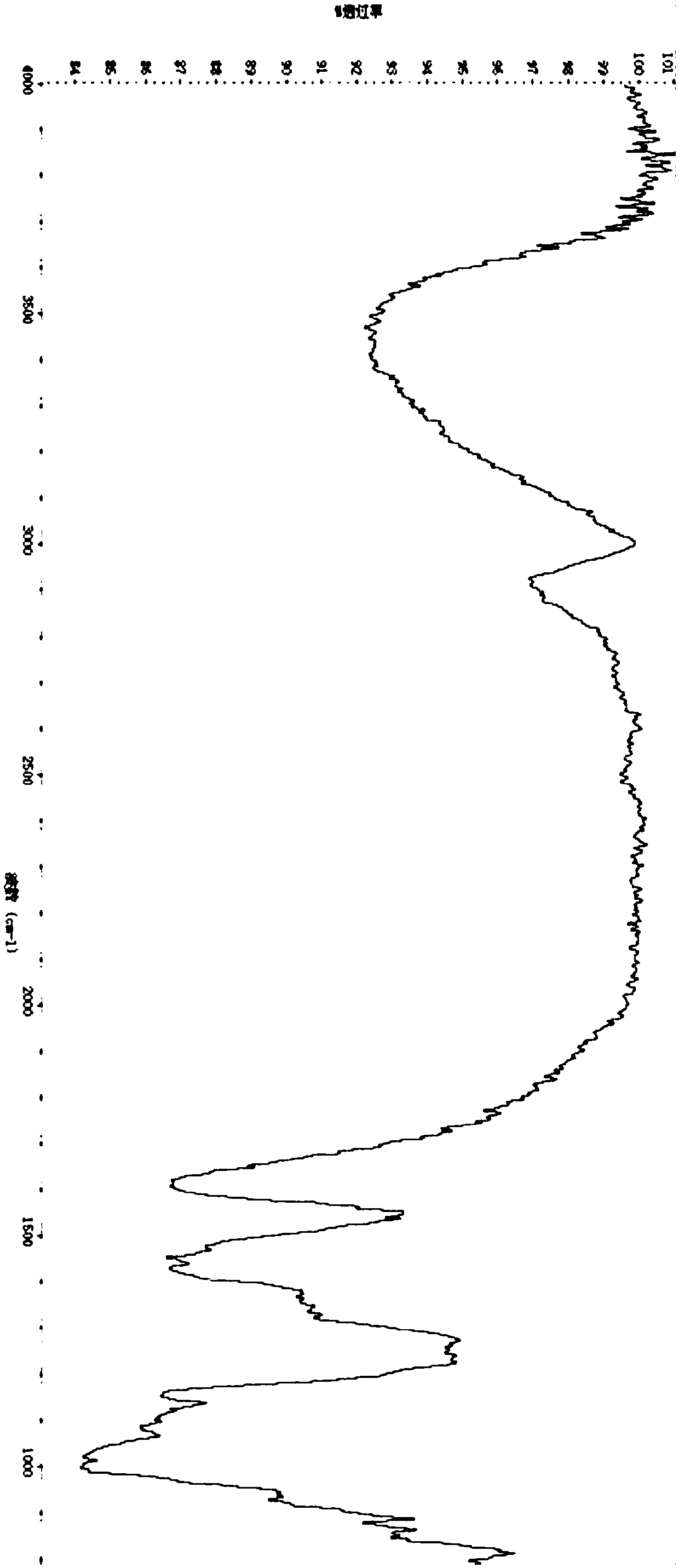

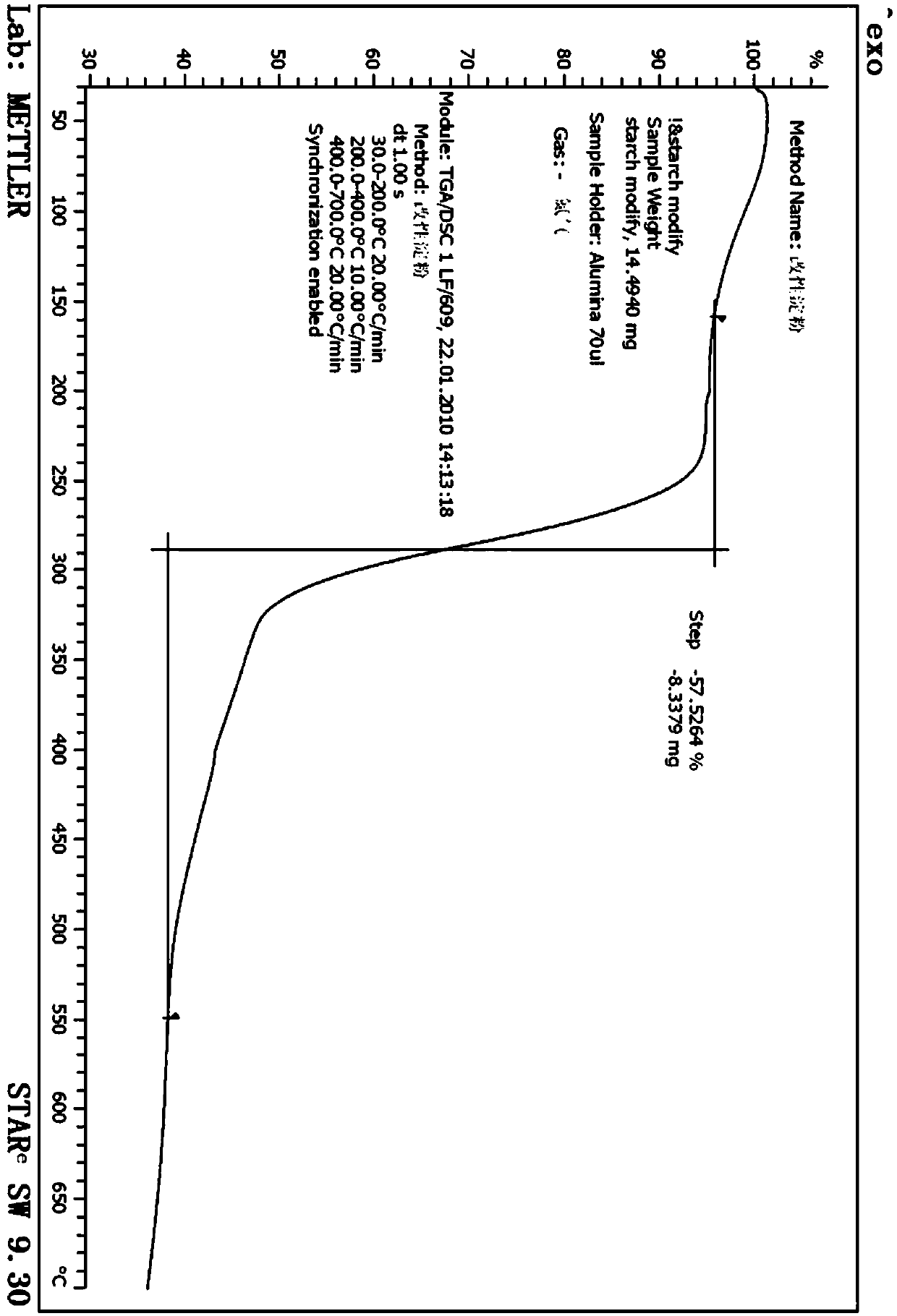

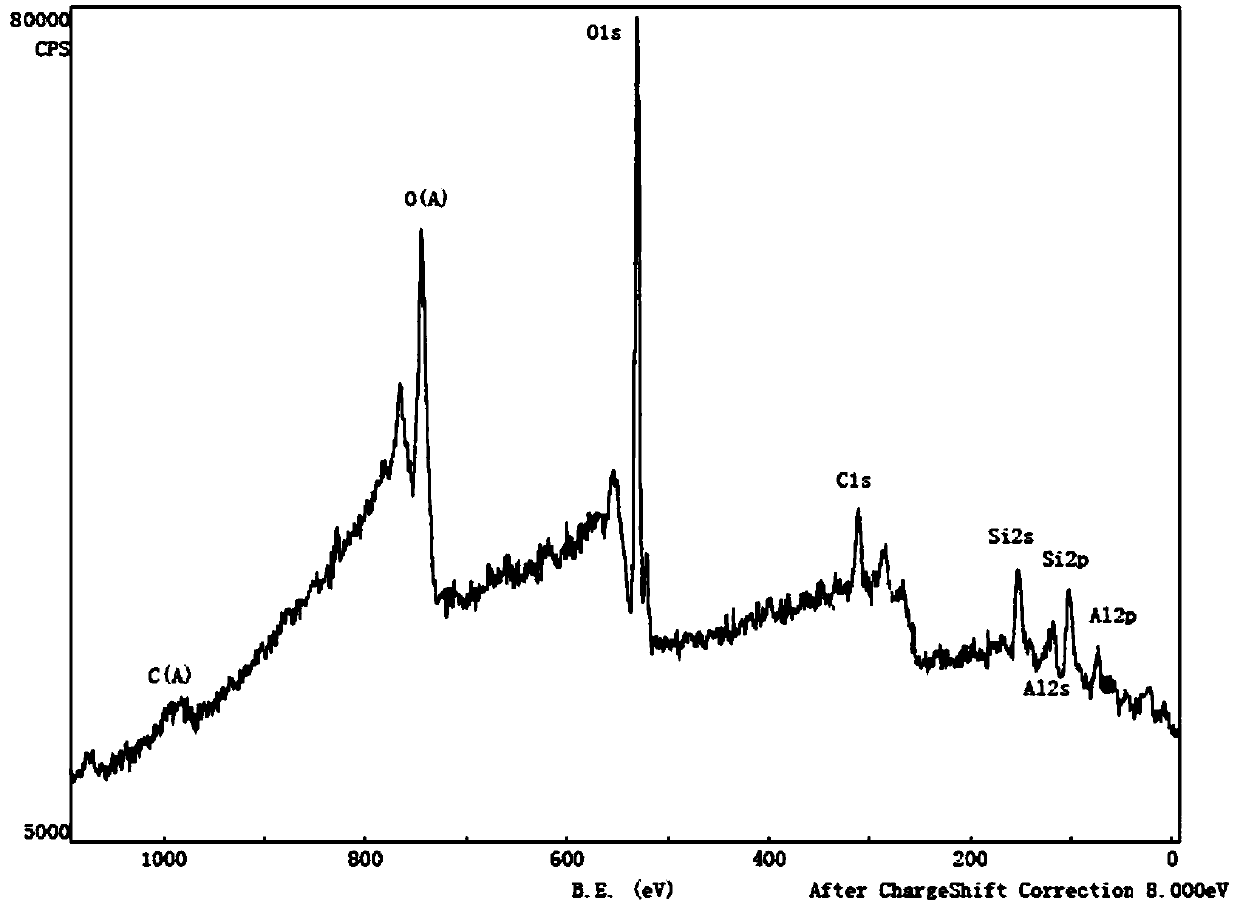

Anti-sloughing modified starch for drilling fluid and preparation method thereof

A technology of drilling fluid and starch, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of unobvious anti-slump performance, achieve good effect of reducing water loss and inhibition, simple product process, and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] (1) 100g of cornstarch is dissolved in pure ethanol, and it is configured into a cornstarch suspension with a weight concentration of 20%, and then 45g of quaternary ammonium salt cationic agent 2,3-epoxypropyltrimethylammonium chloride Dissolve in the cornstarch suspension together with 8g of sodium hydroxide, mix uniformly, obtain the cornstarch slurry;

[0070] (2) 25g concentration is that more than 97% chloroacetic acid is dissolved in ethanol and is configured into the chloroacetic acid solution that weight concentration is 6.5%; 28g sodium hydroxide is dissolved in ethanol and is configured into the catalyst solution that weight concentration is 7%; Get step (1 ) prepared cornstarch slurry was poured into a three-necked bottle, first dropwise added 0.05g of epichlorohydrin, and then added successively all the chloroacetic acid solutions prepared in this step and the catalyst solution prepared in this step of 1 / 4 weight, The temperature was raised to 65° C. in a c...

Embodiment 2

[0073] (1) 90g of cornstarch is dissolved in pure ethanol, and it is configured into a cornstarch suspension with a weight concentration of 18%, and then 35g of quaternary ammonium salt cationic agent 2,3-epoxypropyltrimethylammonium chloride Dissolve in the cornstarch suspension together with 6g of alkaline catalyst sodium hydroxide, and mix uniformly to obtain the cornstarch slurry;

[0074] (2) 20g weight concentration of 97% or more chloroacetic acid is dissolved in ethanol to configure a weight concentration of 5.0% chloroacetic acid solution; 36g basic catalyst sodium hydroxide is dissolved in ethanol to configure a weight concentration of 9% catalyst solution. Take the cornstarch slurry prepared in step (1) and pour it into a three-necked bottle, add 0.06g of epichlorohydrin dropwise in turn, then add all the chloroacetic acid solution prepared in this step and 1 / 8 weight of the prepared in this step The catalyst solution was heated to 50° C. in a constant temperature w...

Embodiment 3

[0077] (1) the cornstarch of 110g is dissolved in pure ethanol, is configured into weight concentration and is 22% cornstarch suspension, then 55g quaternary ammonium salt cationic agent 2,3-epoxypropyltrimethylammonium chloride and 9g alkaline catalyst sodium hydroxide is dissolved in the cornstarch suspension together, mixes evenly, obtains cornstarch slurry;

[0078] (2) 26g weight concentration is that more than 97% chloroacetic acid is dissolved in ethanol and is configured into the chloroacetic acid solution that weight concentration is 6%; 24g sodium hydroxide is dissolved in ethanol and is configured into the catalyst solution that weight concentration is 6%; Get step ( 1) Pour the prepared cornstarch slurry into a three-necked bottle, add 0.07g epichlorohydrin dropwise, and then add all the chloroacetic acid solutions prepared in this step and the catalyst solution prepared in this step of 3 / 8 weight in turn, in The temperature was raised to 50° C. in a constant tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com