Nano material and preparation method thereof, electrode and secondary battery

A technology of nanomaterials and mixed liquids, applied in the direction of non-aqueous electrolyte batteries, negative electrodes, battery electrodes, etc., can solve the problems of low Coulombic efficiency, poor cycle stability, low rate performance, etc., to shorten the transmission path, improve efficiency, improve Effect of specific capacity performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing nanomaterials, comprising the steps of:

[0029] S01, dissolving the metal precursor, phosphorus source and nitrogen-containing organic matter in a solvent to prepare a mixed solution;

[0030] S02, heating the mixed solution to prepare a precursor;

[0031] S03. Calcining the precursor in an inert gas atmosphere to prepare a nitrogen-doped carbon-coated pyrophosphate material.

[0032] Specifically, in step S01, a metal precursor, a phosphorus source, and a nitrogen-containing organic compound are dissolved in a solvent to prepare a mixed solution. Among them, metal precursors and phosphorus sources are used as synthetic pyrophosphates (such as SnP 2 o 7 ), using nitrogen-containing organics as raw materials for the synthesis of nitrogen-doped carbon-coated materials, dissolving metal precursors, phosphorus sources, and nitrogen-containing organics in solvents to construct subsequent synthesis of nitrogen-doped carbon-coated pyrophosphate The...

Embodiment 1

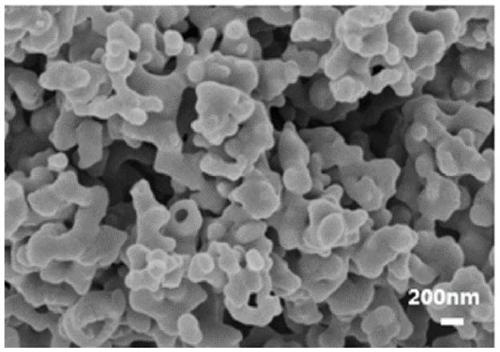

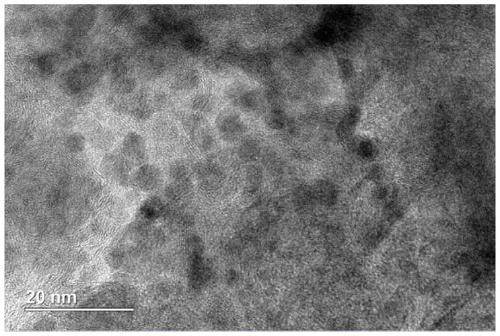

[0078] This embodiment provides a nitrogen-doped carbon-coated tin pyrophosphate material, and its preparation method specifically includes the following steps:

[0079] (1) 10mmol of SnCl 2 2H 2 O was added to 50ml of deionized water, 2mmol of phytic acid and 8mmol of melamine were added, and vigorously stirred at 55°C for 2h to obtain a mixed solution;

[0080] (2) Transfer the mixed solution to a two-necked flask, add 50ml of absolute ethanol, then heat and reflux at 85°C for 12h, centrifuge to collect the precipitate, wash it several times with ethanol and water, and dry it in a vacuum oven at 70°C 12h, obtain the precursor;

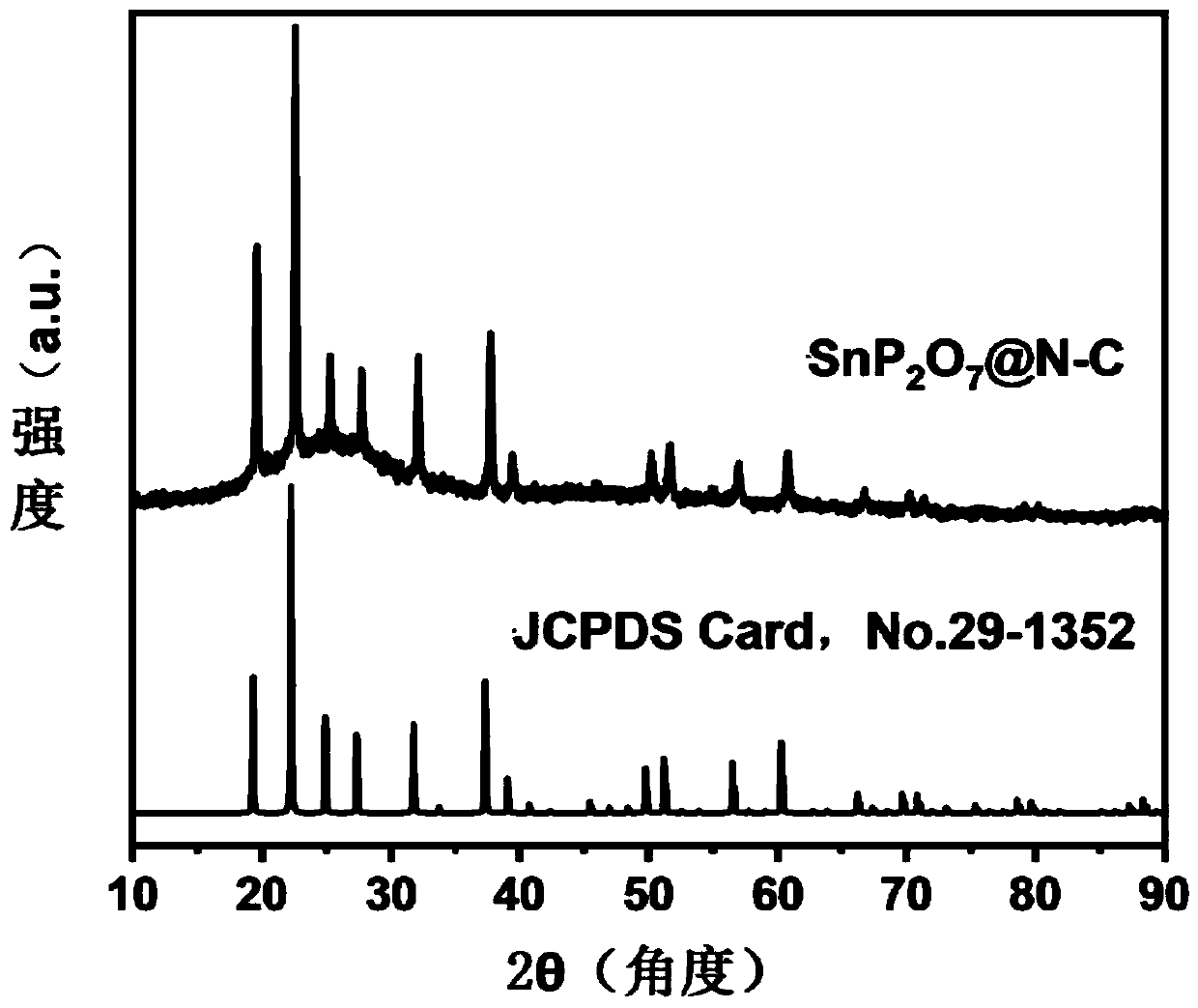

[0081] (3) Under an argon atmosphere, the precursor was reacted at 600 °C for 2 h to obtain the nitrogen-doped carbon-coated tin pyrophosphate material SnP 2 o 7 @N-C.

Embodiment 2

[0083] The difference between this embodiment and embodiment 1 is that in step (3), the precursor is reacted at 700° C. for 2 hours; other parts are basically the same as those of embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com