Hydrocarbon steam conversion lower-stage catalyst and preparation method thereof

A catalyst and steam technology, which is applied to the lower stage catalyst of hydrocarbon steam reforming and the field of preparation thereof, can solve the problems such as the unmentioned waste catalyst of catalytic cracking, achieve good stability of catalyst structure and activity, reduce preparation cost and high thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

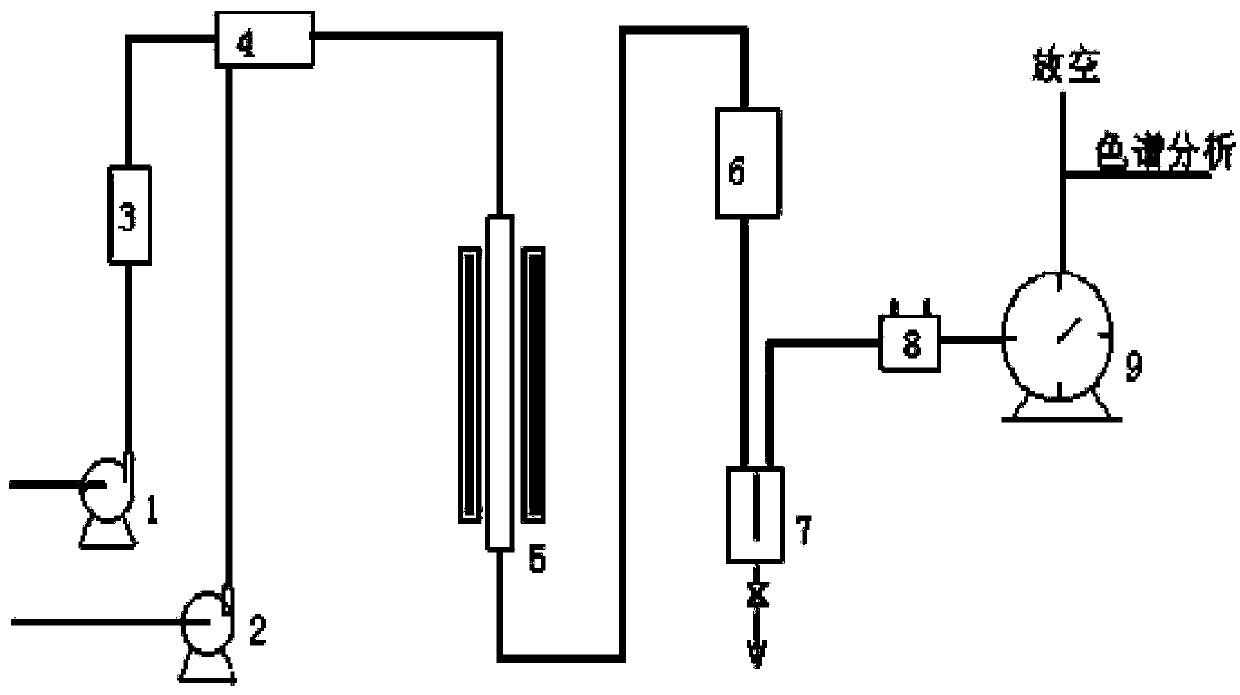

Image

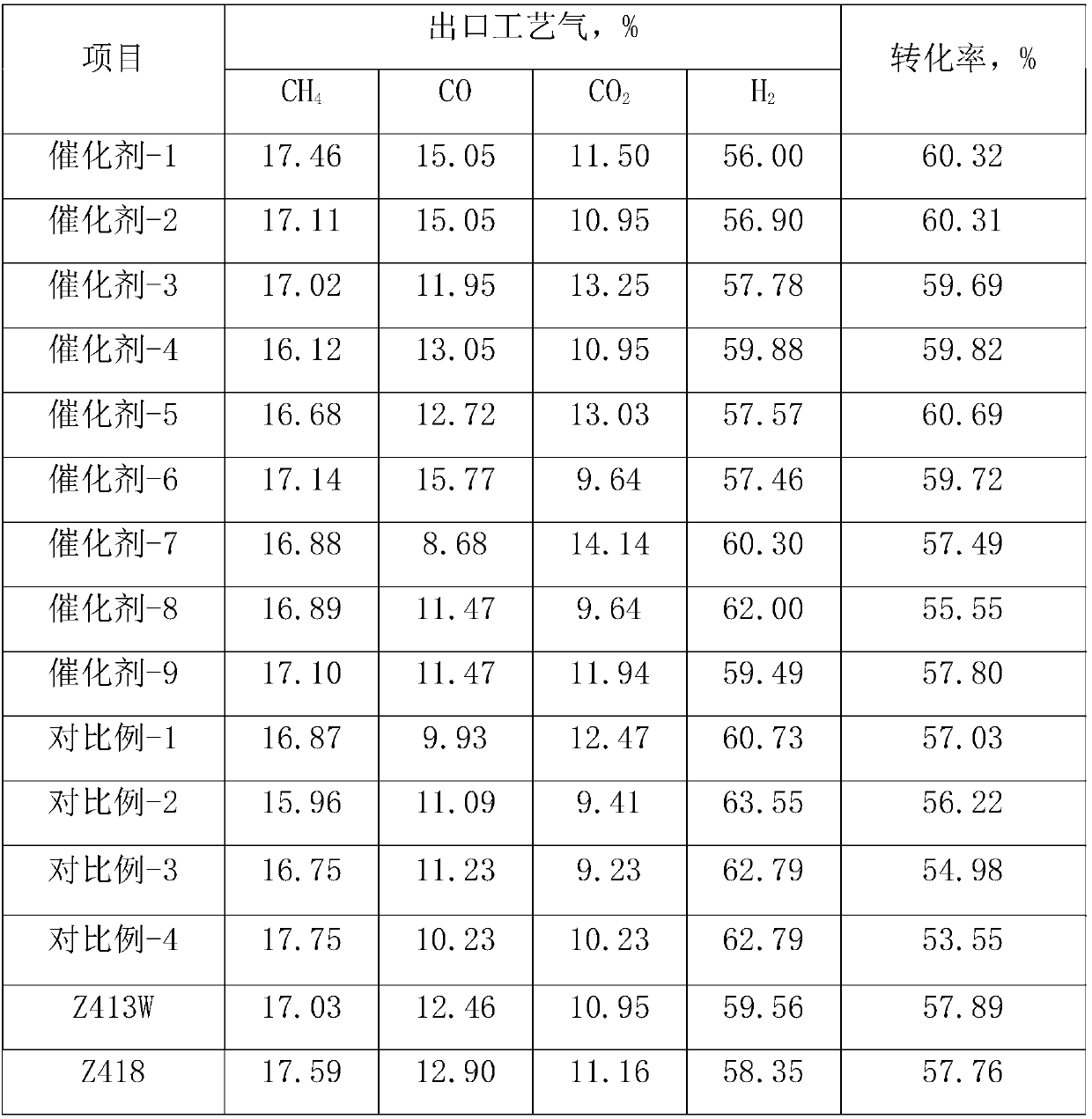

Examples

Embodiment 1

[0031] RGD-1 (taken from Sinopec Catalyst Qilu Branch, 2016; contains about 34% (m / m) SiO 2 , About 53% (m / m) of Al 2 O 3 , The remainder includes iron, nickel, vanadium, sodium, etc., which can be washed away by acid.) The waste agent is soaked and washed with 30% nitric acid for 2 hours, taken out and drained, and roasted to remove carbon deposits. The latter waste agent is crushed through a 200-mesh sieve.

[0032] Weigh 872.43g of nickel nitrate, add water to dissolve it, and adjust the pH value with nitric acid to prepare a 1L nickel nitrate solution with a pH value of 2.

[0033] Mix 75 g of the roasted RGD-1 waste agent with 33.4 mL of nickel nitrate solution, stir evenly, stand for 6 hours, dry at 120°C, and then roast at 400°C for 6 hours. Then mix the above materials with 33.4 mL of nickel nitrate solution, stir evenly, stand for 6 hours, dry at 120°C, and then roast at 600°C for 4 hours to obtain semi-finished product-1.

[0034] Mix the semi-finished product-1 with 1g se...

Embodiment 2

[0039] The RGD-1 (sampling from the same batch as in Example 1) was soaked and washed with 35% nitric acid for 10 hours, taken out and drained, and roasted to remove carbon deposits. The roasting temperature was 700°C and the roasting time was 10 hours. The waste agent is crushed through a 240 mesh sieve.

[0040] Weigh 1221.40g of nickel nitrate, add water to dissolve it, and adjust the pH value with nitric acid to prepare a 1L nickel nitrate solution with a pH value of 5.

[0041] Mix 87 g of roasted RGD-1 waste agent with 12.7 mL of nickel nitrate solution, stir evenly, stand for 0.5 h, dry at 120°C, and then roast at 700°C for 1 hour. Then mix the above materials with 12.7 mL of nickel nitrate solution, stir evenly, stand for 1 hour, dry at 120°C, and then roast at 500°C for 2 hours to obtain semi-finished product-2.

[0042] Mix the semi-finished product-2 with 6g sesame powder, 1g citric acid, 5g calcium aluminate cement (calcium dialuminate phase accounted for 85%), mix well,...

Embodiment 3

[0047] The RGD-1 (sampling from the same batch as in Example 1) was soaked and washed with 10% nitric acid for 10 hours, taken out and drained, and roasted to remove carbon deposits. The roasting temperature was 600°C and the roasting time was 4 hours. The waste agent is crushed through a 220-mesh sieve.

[0048] Weigh 1017.84g of nickel nitrate, add water to dissolve it, and adjust the pH value with nitric acid to prepare a 1L nickel nitrate solution with a pH value of 2.2.

[0049] Mix 68 g of the roasted RGD-1 waste agent with 22.9 mL of nickel nitrate solution, stir evenly, stand for 3 hours, dry at 120°C, and then roast at 450°C for 3 hours. Then mix the above materials with 22.9 mL of nickel nitrate solution, stir evenly, stand for 3 hours, dry at 120°C, and then roast at 450°C for 3 hours to obtain semi-finished product-3.

[0050] The semi-finished product-3 is mixed with 4 g of sesame powder, 20 g of calcium aluminate cement (calcium dialuminate phase accounts for 75%), mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com