Carbon nano-sieve based on pearl layer, and preparation method thereof

A technology of carbon nano and nacre, which is applied in the direction of nano carbon, can solve the problems of uneven distribution of carbon nano sieve pore size, cumbersome preparation of templates, loss of carbon, etc., and achieve clever design, low operating cost and high conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing a carbon nanosieve based on nacre, comprising the steps of:

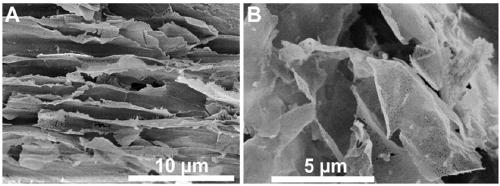

[0039] 1) Wash Hepu mother-of-pearl shells with plenty of water, and use a brush to remove surface deposits. Then use a grinding wheel to remove the shell layer and the prism layer to obtain the nacre layer.

[0040] 2) Soak the obtained pearl layer in 0.5M sulfuric acid aqueous solution, and soak for 6 days at 35°C to fully dissolve the inorganic matter, and then use clean water to filter and wash the obtained organic matter for several times (the filter membrane pore size is 450nm), until the upper layer is medium properties, suction filtered to remove excess water for later use.

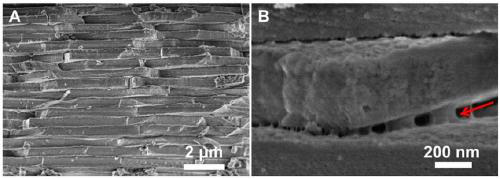

[0041] 3) The above-mentioned organic fraction was redispersed in tert-butanol, ultrasonicated at 80KHz, 100W for 60min, the resulting dispersion was frozen at -26°C, and freeze-dried at -10°C.

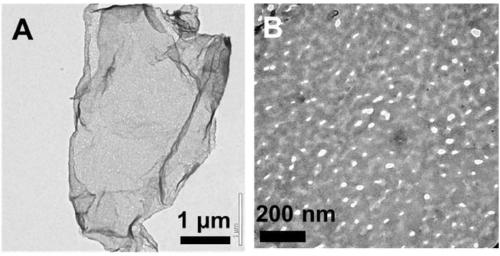

[0042] 4) The organic powder obtained above was heated to 500° C. under an atmosphere protected by argon (gas ...

Embodiment 2

[0045] A method for preparing a carbon nanosieve based on nacre, comprising the steps of:

[0046] 1) Wash the abalone shell with plenty of water to remove the sediment on the surface. Then, the surface layer and the prism layer of the abalone shell are polished with polishing grinding head, grinding wheel and wool felt successively.

[0047] 2) Soak the obtained nacre in 1M aqueous hydrochloric acid solution for 5 days at 25°C to fully dissolve the inorganic matter, then use clean water at 5000 rpm and 10 min to centrifuge and wash the obtained organic matter several times until the supernatant is neutral. spare.

[0048] 3) The above-mentioned organic fraction was redispersed in pure water, ultrasonicated at 45KHz, 150W for 30min, and the resulting dispersion was frozen at -176°C and freeze-dried at -56°C.

[0049] 4) Heat the organic matter powder obtained in the previous step to 700° C. under a nitrogen-protected atmosphere (nitrogen flow rate: 100 mL / min, heating rate: ...

Embodiment 3

[0052] A method for preparing a carbon nanosieve based on nacre, comprising the steps of:

[0053] 1) Wash Hepu mother-of-pearl shells with plenty of water, and use a brush to remove surface deposits. Then use a grinding wheel to grind out the case layer and prism layer to obtain the pearl layer.

[0054] 2) Soak the obtained pearl layer in 3M acetic acid, soak for 8 days at 45°C to fully dissolve the inorganic matter, then use clear water to filter and wash the obtained organic matter several times (the filter membrane pore size is 220nm), until the upper layer is neutral, spare.

[0055] 3) The above-mentioned organic fraction was redispersed in dimethyl sulfoxide, ultrasonicated at 45K Hz, 200W for 45min, the resulting dispersion was frozen at -20°C, and freeze-dried at -5°C.

[0056] 4) The organic powder obtained above was heated to 800° C. under a helium-protected atmosphere (gas flow rate: 80 mL / min, heating rate: 2° C. / min). The obtained sample was soaked in 1M hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com