Preparation method of nano white carbon black used as rubber filler

A technology of nano-silica and rubber filler, which is applied in the field of preparation of synthetic rubber filler nano-silica with high dispersibility, can solve the problems such as easy agglomeration of nano-silica, and achieve large molecular steric hindrance effect and modification cost. Low, high connection strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

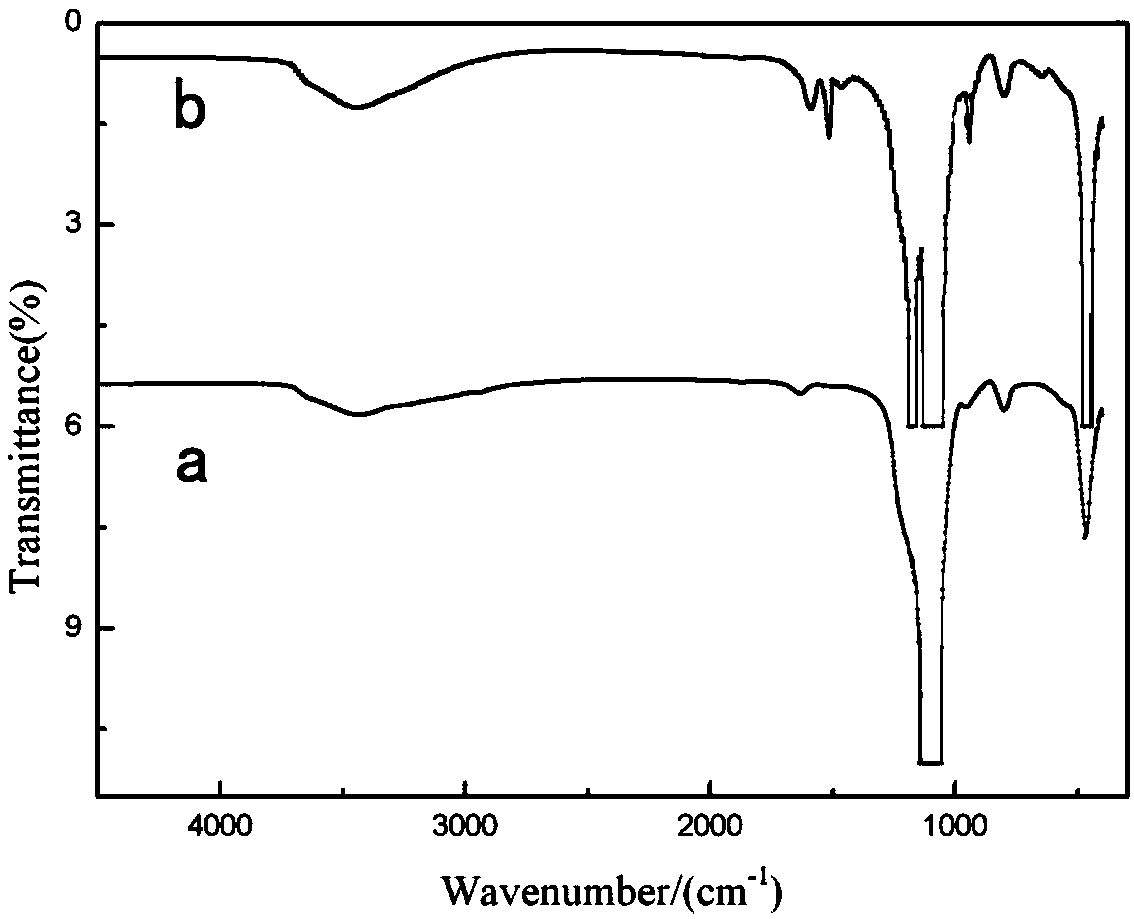

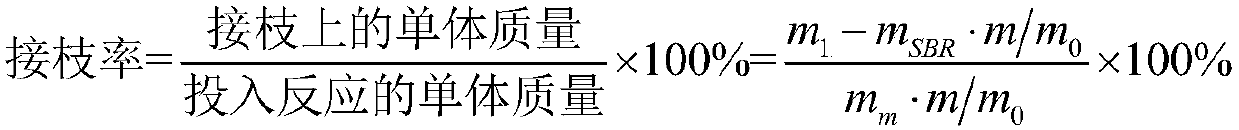

[0048] (1) Preparation of grafted polystyrene: first add 100 parts of HIPS and 300 parts of xylene in the reaction kettle, and when heated to 50°C, stir for 5 hours. After the polystyrene is completely dissolved, add 5 parts of phthalic acid And 0.05 parts of DCP, after stirring for 1 hr, 5 parts of diethylhydroxylamine was added to terminate the reaction, and after suction filtration and washing, polystyrene graft a (grafting rate 0.9%) was obtained.

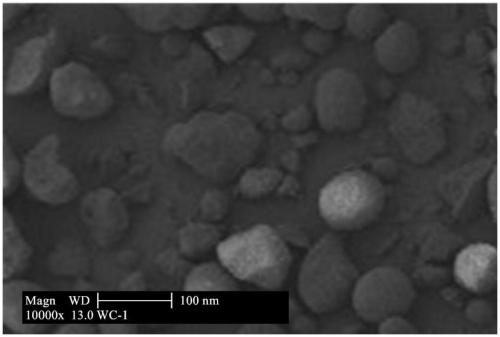

[0049] (2) Preparation of highly dispersed nano-silica: Take 100 parts of nano-silica (40nm), 5 parts of DINP, and 200 parts of cyclohexane into the polymerization kettle, heat up to 40 ° C, stir for 1 hr; then add 7 parts of polystyrene graft a, stirred and reacted for 2 hours, then flashed, dried and ground to obtain highly dispersed nano-silica. Sampling and analysis: standard samples were made, and the tested properties are shown in Table 1.

Embodiment 2

[0051] (1) Preparation of grafted polystyrene: with embodiment 1.

[0052] (2) Preparation of highly dispersed nano-silica: 100 parts of nano-silica (40nm), 7 parts of DINP, and 260 parts of cyclohexane were added to the polymerization kettle, the temperature was raised to 45°C, and the reaction was stirred for 1.5hr; then Add 9 parts of polystyrene graft a, stir and react for 2.5 hours, then flash, dry and grind to obtain high-dispersion nano-silica. Sampling and analysis: standard samples were made, and the tested properties are shown in Table 1.

Embodiment 3

[0054] (1) Preparation of grafted polystyrene: with embodiment 1.

[0055] (2) Preparation of highly dispersed nano-silica: 100 parts of nano-silica (40nm), 9 parts of DINP, and 260 parts of cyclohexane were added to the polymerization kettle, the temperature was raised to 45°C, and the reaction was stirred for 1.5hr; then Add 12 parts of polystyrene graft a, stir and react for 2.5 hours, then flash, dry and grind to obtain high-dispersion nano-silica. Sampling and analysis: standard samples were made, and the tested properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com