Inorganic coating and preparation method thereof

An inorganic coating and inorganic modification technology, applied in fireproof coatings, antifouling/underwater coatings, alkali metal silicate coatings, etc., can solve the problems of no additional function and single function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of this kind of inorganic coating comprises the following steps:

[0043] Step 1, under stirring state, mix deionized water and hydroxyethyl cellulose; stir under new stirring state until hydroxyethyl cellulose is completely dissolved to obtain hydroxyethyl cellulose liquid;

[0044] Step 2, under stirring state, mix the hydroxyethyl cellulose liquid, the dispersant and the defoamer evenly to obtain the dispersion liquid;

[0045] Step 3: Mix the dispersion liquid, titanium dioxide, superfine ground calcium carbonate, talcum powder and negative ion coating additives evenly under the stirring state, and obtain the negative oxygen ionic liquid after stirring under the new stirring state;

[0046] Step 4: Mix the negative oxygen ionic liquid, odor-cleaning emulsion, inorganic modified silicate, water resistance agent and viscosity stabilizer evenly under stirring to obtain a stable liquid;

[0047] Step 5, adjusting the viscosity of the stabilized s...

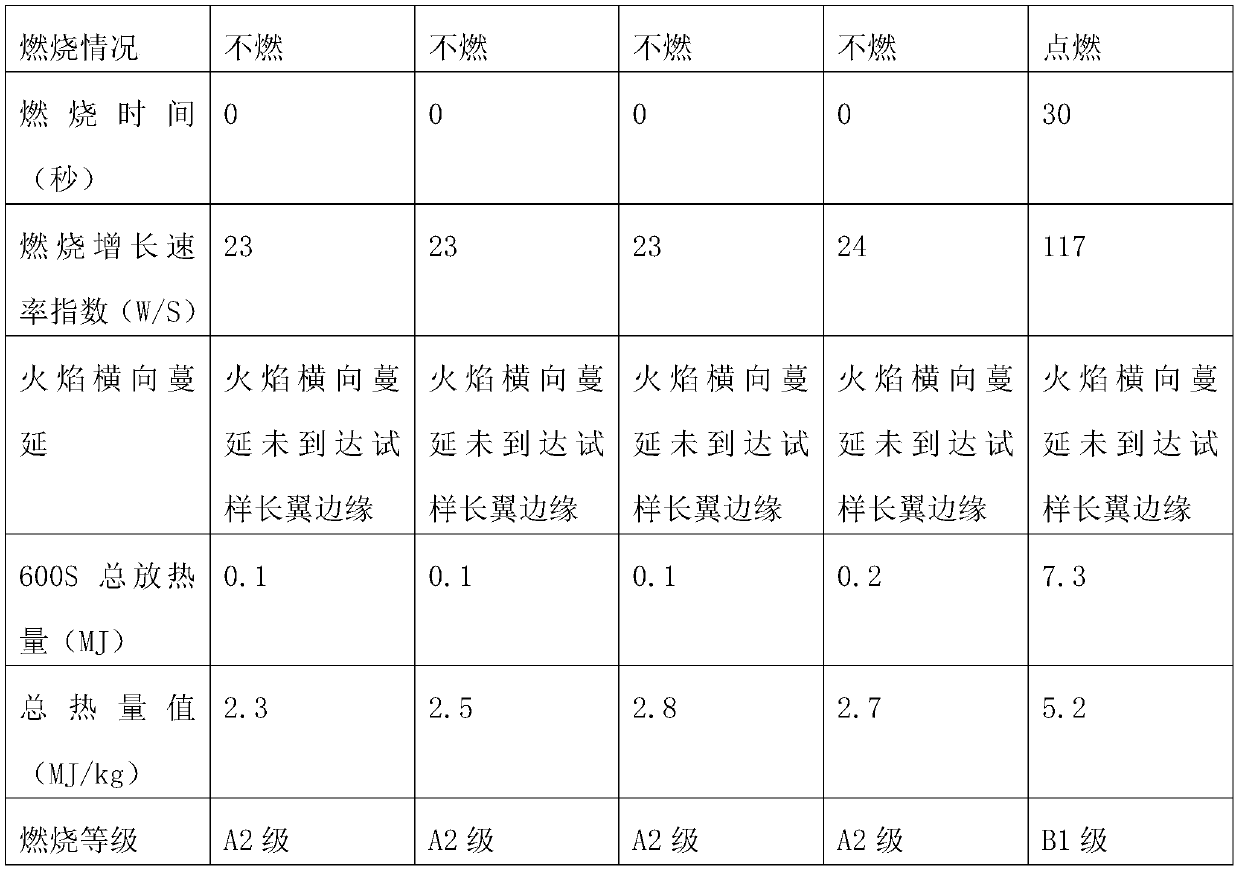

Embodiment 1

[0058] The inorganic coating in the present embodiment comprises the raw material of following parts by weight:

[0059] 0.17 parts of hydroxyethyl cellulose; 0.48 parts of dispersant; 4.86 parts of titanium dioxide; 26.32 parts of superfine ground calcium carbonate; 5.22 parts of talcum powder; 12.24 parts; 1.44 parts of viscosity stabilizer; 0.50 parts of defoamer; 0.25 parts of water resistance agent; 16.24 parts of deionized water;

[0060] When preparing the inorganic coating, the stirring speed in the stirring state of step 1 is 250r / min. The stirring speed of the new stirring state in step 1 is 650r / min. The stirring speed in the stirring state of step 2 is 650r / min. The stirring speed of the stirring state in the step 3 is 650r / min, and the stirring speed of the new stirring state of the step 3 is 1350r / min. The fineness of the solid particles in the negative oxygen ionic liquid in step 3 is equal to 20 μm. The stirring speed in the stirring state of step 4 is 650r...

Embodiment 2

[0062] The inorganic coating in the present embodiment comprises the raw material of following parts by weight:

[0063] 0.27 parts of hydroxyethyl cellulose; 0.98 parts of dispersant; 7.86 parts of titanium dioxide; 29.32 parts of superfine ground calcium carbonate; 7.72 parts of talcum powder; 16.24 parts; 2.04 parts of viscosity stabilizer; 1.00 parts of defoamer; 0.35 parts of water resistance agent; 26.24 parts of deionized water;

[0064] When preparing the inorganic coating, the stirring speed in the stirring state of step 1 is 300 r / min. The stirring speed of the new stirring state in step 1 is 750r / min. The stirring speed in the stirring state of step 2 is 750r / min. The stirring speed of the stirring state in step 3 is 750r / min, and the stirring speed of the new stirring state of step 3 is 1450r / min. The fineness of the solid particles in the negative oxygen ionic liquid in step 3 is equal to 35 μm. The stirring speed in the stirring state of step 4 is 750r / min. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com