Self-emulsifying blockage removing liquid and preparation method thereof

A non-ionic emulsifier and mixed liquid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of entanglement between polymers and heavy oil, difficulty in unblocking, high cost of use, etc., and reduce the oil-water interface High tension, high safety, corrosion-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

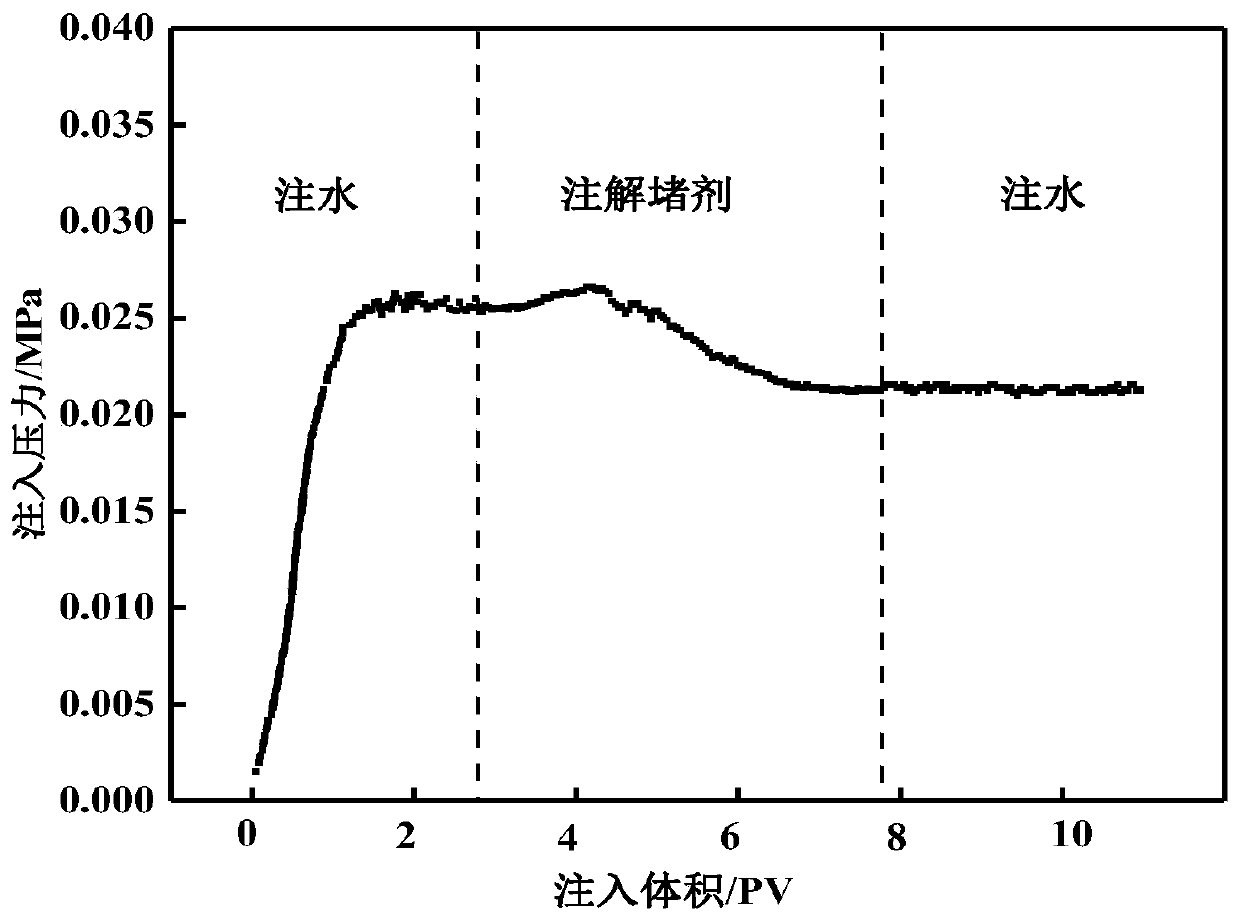

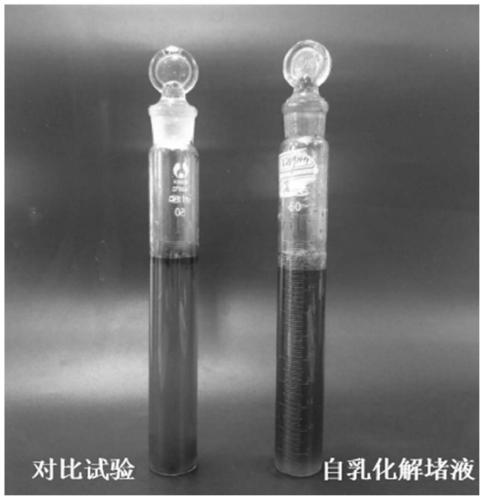

Image

Examples

Embodiment 1

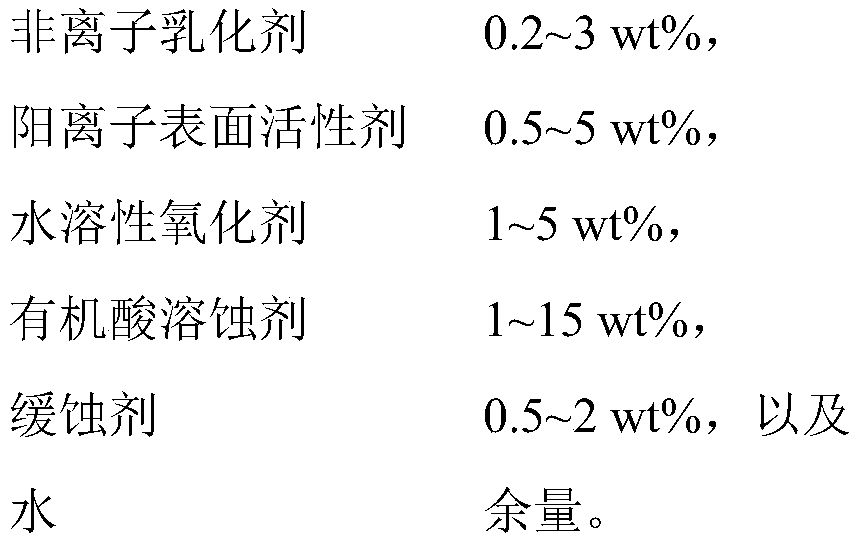

[0058] This embodiment 1 provides a kind of self-emulsifying plug-removing liquid, and the raw material component of this self-emulsifying plug-removing liquid comprises:

[0059]

[0060]

[0061] The preparation method of the self-emulsifying plug-removing liquid provided in the present embodiment 1 comprises the following steps:

[0062] Add 1g of polyvinyl alcohol into the container, add 10g of distilled water, set the stirring speed to 300r / min, and stir evenly at 45°C to obtain the mixed solution A, which is put into a sealed container for later use; then, add 62g of distilled water, 5g of hexadecyl Trimethylammonium bromide, 5g ammonium persulfate, 15g citric acid, 2g imidazoline quaternary ammonium salt are mixed under stirring at 300r / min to obtain mixed solution B; finally, mixed solution A is mixed with mixed solution B, and mixed at 1000r / min After stirring evenly under 1 min, a self-emulsifying plug-removing solution was obtained, which was sealed for later us...

Embodiment 2

[0069] This embodiment 2 provides a self-emulsifying plug-removing liquid, and the raw material components of the self-emulsifying plug-removing liquid include:

[0070]

[0071] The preparation method of the self-emulsifying plug-removing liquid provided by the present embodiment 2 comprises the following steps:

[0072] Add 0.5g of polyoxyethylene octylphenol ether-10 into the container, add 5g of distilled water, set the stirring speed to 300r / min, and stir evenly at 45°C to obtain the mixed solution A, which is put into a sealed container for later use; then, add 76g of distilled water , 3g cetyltrimethylammonium bromide, 4g urea peroxide, 10g citric acid, 1.5g Mannich base are mixed uniformly under stirring at 300r / min to obtain mixed solution B; finally, mixed solution A and The mixed solution B is mixed, stirred evenly at 500r / min to obtain a self-emulsifying plug-removing solution, which is sealed for later use.

[0073] The self-emulsifying plug-removing solution ...

Embodiment 3

[0075] This embodiment 3 provides a kind of self-emulsifying plug-removing liquid, and the raw material component of this self-emulsifying plug-removing liquid comprises:

[0076]

[0077] The preparation method of the self-emulsifying plug-removing liquid provided by the present embodiment 3 comprises the following steps:

[0078] Add 2g of polyoxyethylene octylphenol ether-10 into the container, add 10g of distilled water, set the stirring speed to 300r / min, and stir evenly at 45°C to obtain the mixed solution A, which is put into a sealed container for later use; then, add 62.5g of distilled water , 5g dodecyltrimethylammonium chloride, 4g ammonium persulfate, 15g citric acid, 1.5g polyoxyethylene alkylphenol ether are mixed under stirring at 300r / min to obtain mixed solution B; finally, mixed solution A Mix it with mixed solution B, stir evenly at 1000r / min to obtain a self-emulsifying plug-removing solution, and seal it for later use.

[0079] The self-emulsifying plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com