Organic electroluminescent device

An electroluminescent device and organic light-emitting layer technology, applied in circuits, electrical components, electrical solid-state devices, etc., can solve the problems of reduced yield, increased cost, and complicated process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

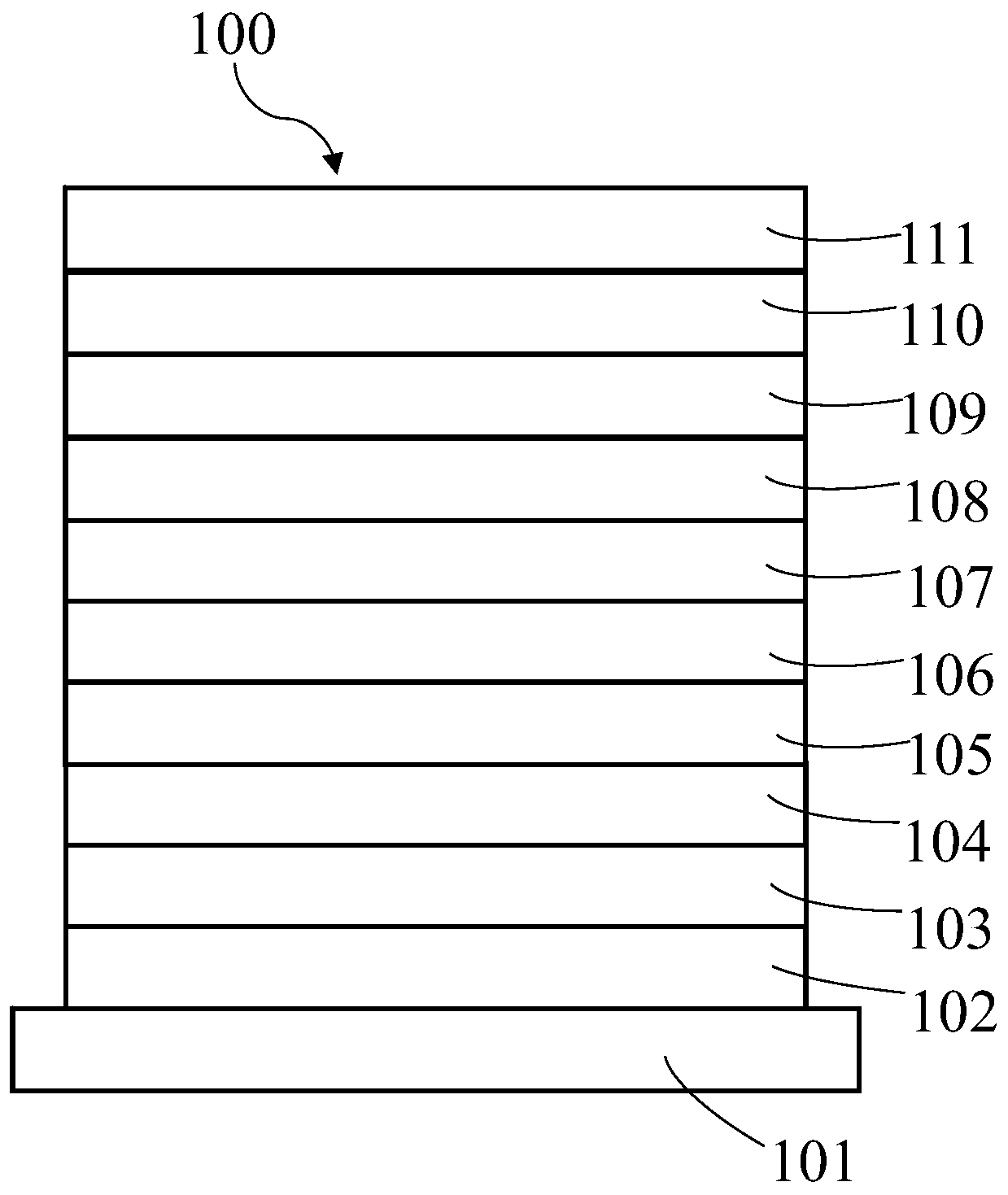

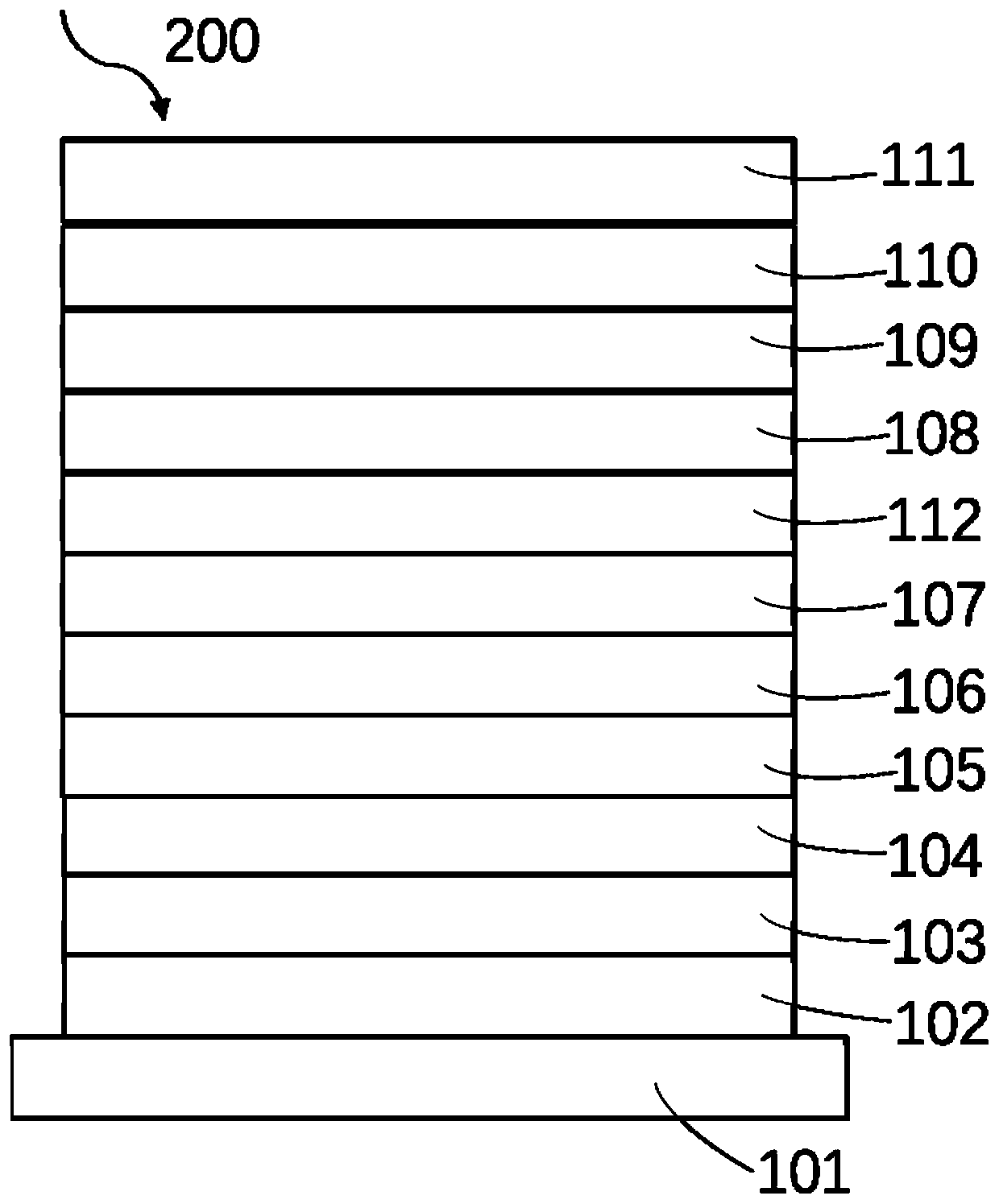

[0070] First, we prepared OLED units that can emit near-infrared and red light. The device structure is as follows: Figure 1a Device 100 is shown. First, the glass substrate 101, on which a patterned 120 nm-thick indium tin oxide (ITO) anode 102 was previously coated, was cleaned with ultrapure water, and the ITO surface was treated with UV ozone and oxygen plasma. Afterwards, the substrate was dried in a nitrogen-filled glove box to remove moisture, then mounted on a stand and loaded into an evaporation chamber. The organic layer specified below, at a vacuum of about 1*10 -6 In the case of Torr, a film is sequentially coated on the ITO anode 102 by thermal evaporation at a rate of 0.01-5 angstroms / second. Firstly, the compound HI was vapor-deposited as a hole injection layer (HIL) 103 with a thickness of 100 angstroms. Compound HT was used as hole transport layer (HTL) 104 with a thickness of 400 angstroms. Compound H-1 was used as an electron blocking layer (EBL) 105 wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com