Lithium thionyl chloride battery cathode sheet containing pitch coke activated carbon catalytic material and preparation method thereof

A technology of lithium thionyl chloride battery and catalytic material, which is applied to the electrodes of primary batteries and non-aqueous electrolyte batteries, etc., which can solve the problems of carbon electrode blockage, increase of battery contact resistance, and influence of electrolyte diffusion, etc., to improve discharge time and specific energy, good structural matching, and the effect of reducing packing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A method for preparing a lithium thionyl chloride battery cathode sheet containing a pitch coke activated carbon catalytic material disclosed by the invention comprises the following steps:

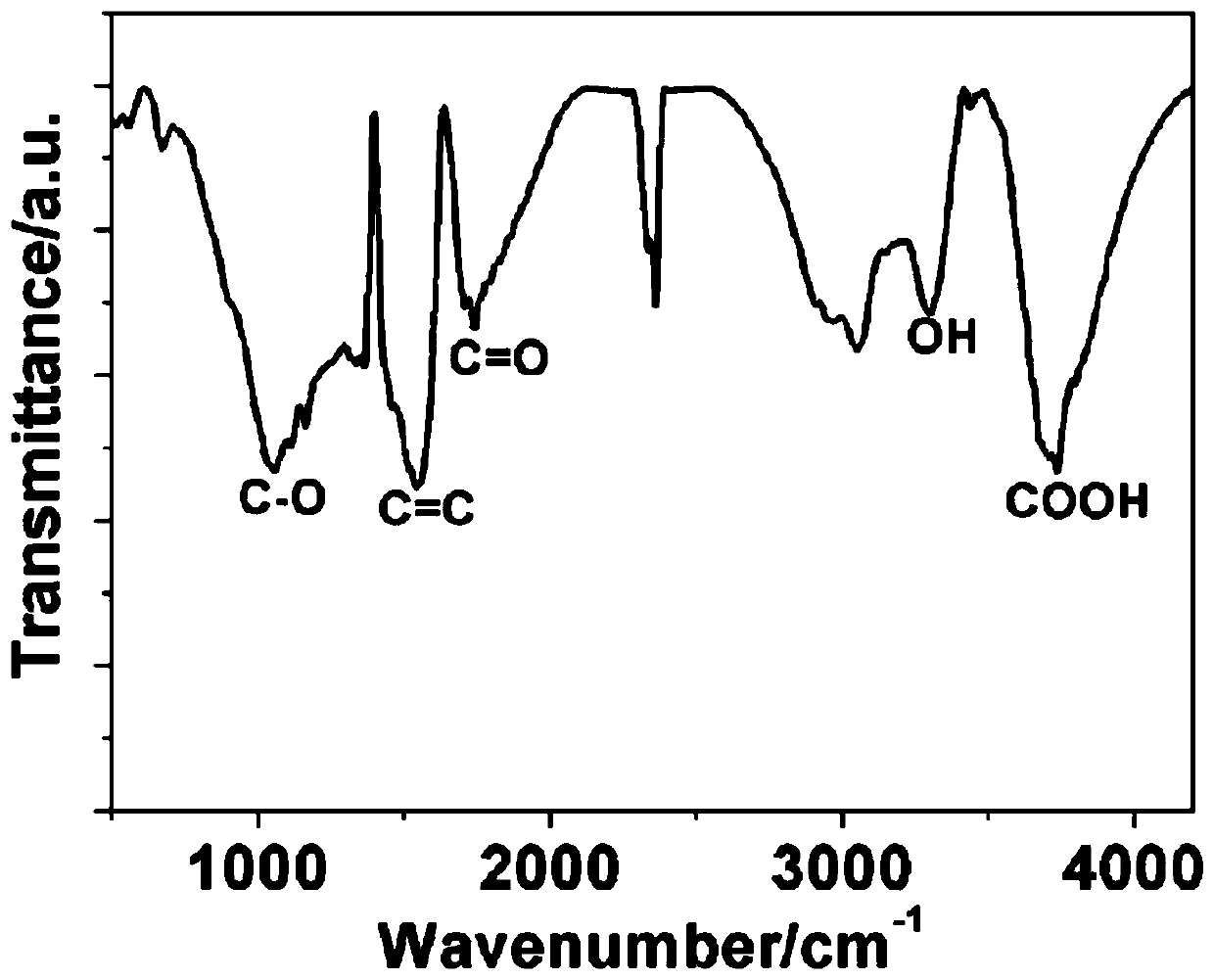

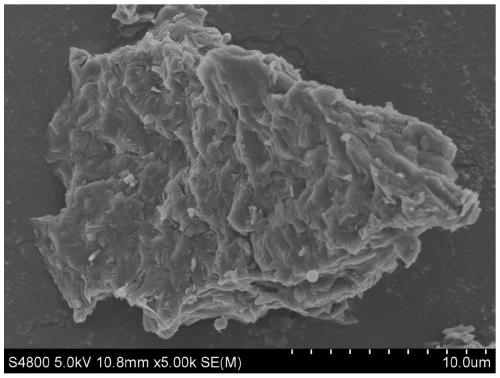

[0028] 1) First, take some pitch coke activated carbon, soak it in beaker A filled with concentrated nitric acid with a mass fraction of 30%, and keep it warm in a water bath. The purpose is to oxidize the pitch coke activated carbon so that its surface contains more functional groups , favoring SOCl 2 Reduction, then filtration, drying to obtain pretreated pitch coke activated carbon;

[0029] 2) Add 5-10g of deionized water into beaker B, then add 0.03-0.10g of PTFE emulsion, stir and dilute evenly to obtain PTFE dilution, which is ready for use;

[0030] 3) Mix the pretreated pitch coke activated carbon and acetylene black obtained in step 1) into the mortar, then gradually add the mixed PTFE dilution into the mortar, stir evenly, grind to a paste and transfer to the mortar. i...

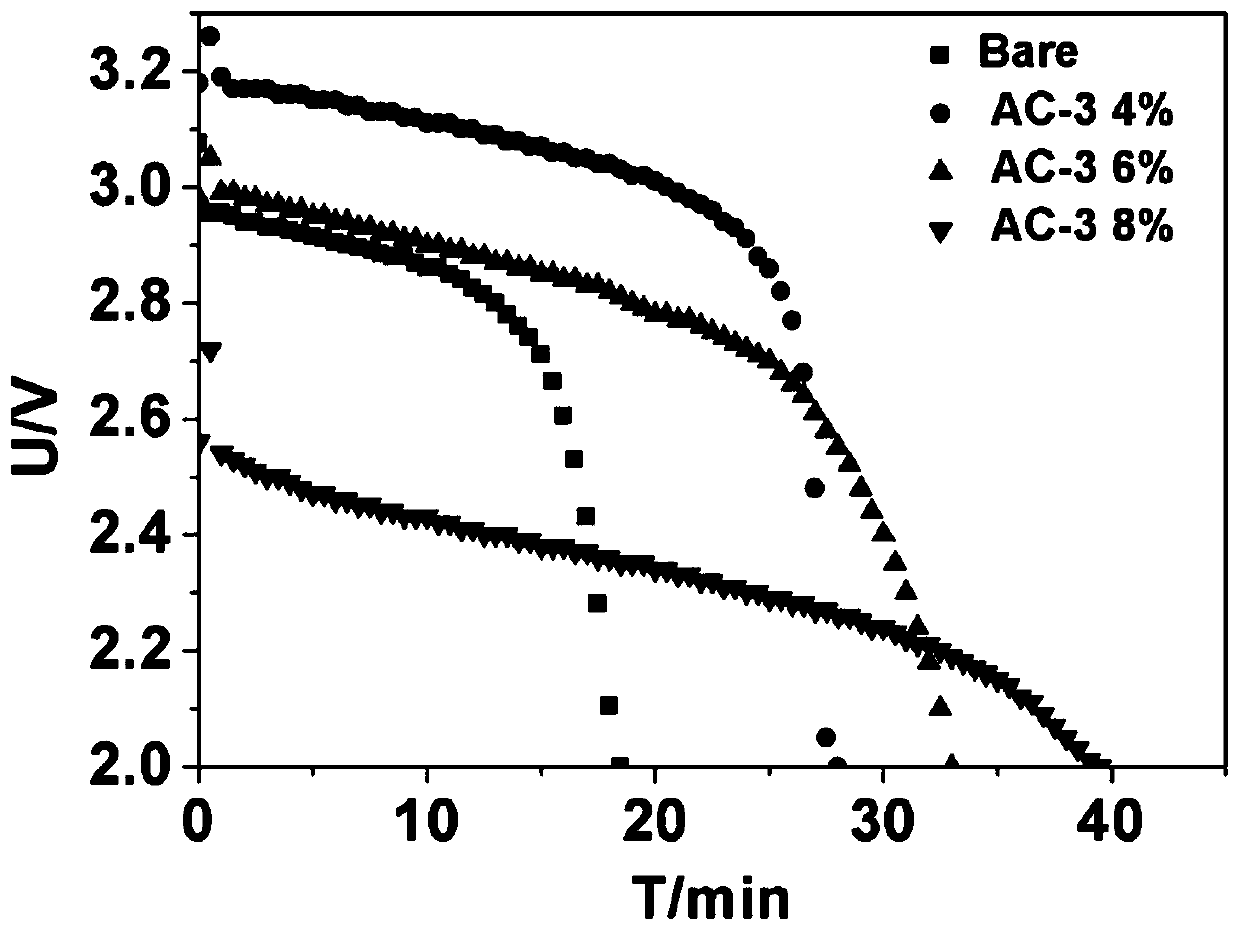

Embodiment 1

[0043] A preparation method of lithium thionyl chloride battery cathode sheet containing pitch coke activated carbon catalytic material, comprising the following steps:

[0044] 1) First take pitch coke activated carbon (1000m 2 / g) several, soak it in the beaker A that is equipped with the concentrated nitric acid that mass fraction is 30%, heat preservation treatment in water bath 60 ℃, time 24 hours, filter, dry, obtain the pitch coke activated carbon after pretreatment;

[0045] 2) Add 6g deionized water to beaker B, then add 0.05g PTFE emulsion, stir and dilute to obtain PTFE dilution, stand-by;

[0046]3) Mix the pitch coke activated carbon and acetylene black treated in step 1) into the mortar according to the mass ratio of 4:100, then gradually add the mixed PTFE dilution into the mortar, stir evenly, and grind to a paste and transfer to an evaporating dish;

[0047] 4) Put the evaporating dish filled with the cathode mixture into an electric blast drying oven, and b...

Embodiment 2

[0054] A preparation method of lithium thionyl chloride battery cathode sheet containing pitch coke activated carbon catalytic material, comprising the following steps:

[0055] 1) First take pitch coke activated carbon (1000m 2 / g) several, soak it in the beaker A that is equipped with the concentrated nitric acid that mass fraction is 30%, heat preservation treatment in water bath 60 ℃, time 24 hours, filter, dry, obtain the pitch coke activated carbon after pretreatment;

[0056] 2) Add 6g deionized water to beaker B, then add 0.05g PTFE emulsion, stir and dilute to obtain PTFE dilution, stand-by;

[0057] 3) Mix the pitch coke activated carbon and acetylene black treated in step 1) and add them into the mortar according to the mass ratio of 6:100, then gradually add the mixed PTFE dilution into the mortar, stir evenly, and grind until it becomes a paste and transfer to an evaporating dish;

[0058] 4) Put the evaporating dish filled with the cathode mixture into an elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com