Preparation method of carbon-coated nitrogen-magnesium-doped porous silicon-based composite material and lithium ion battery

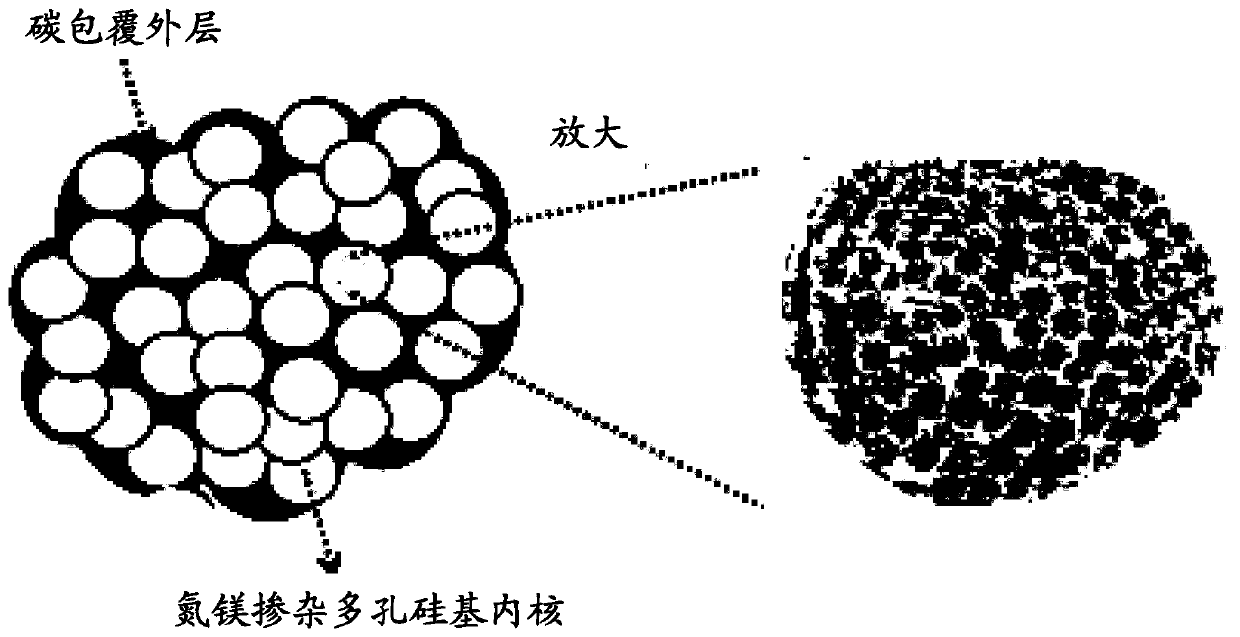

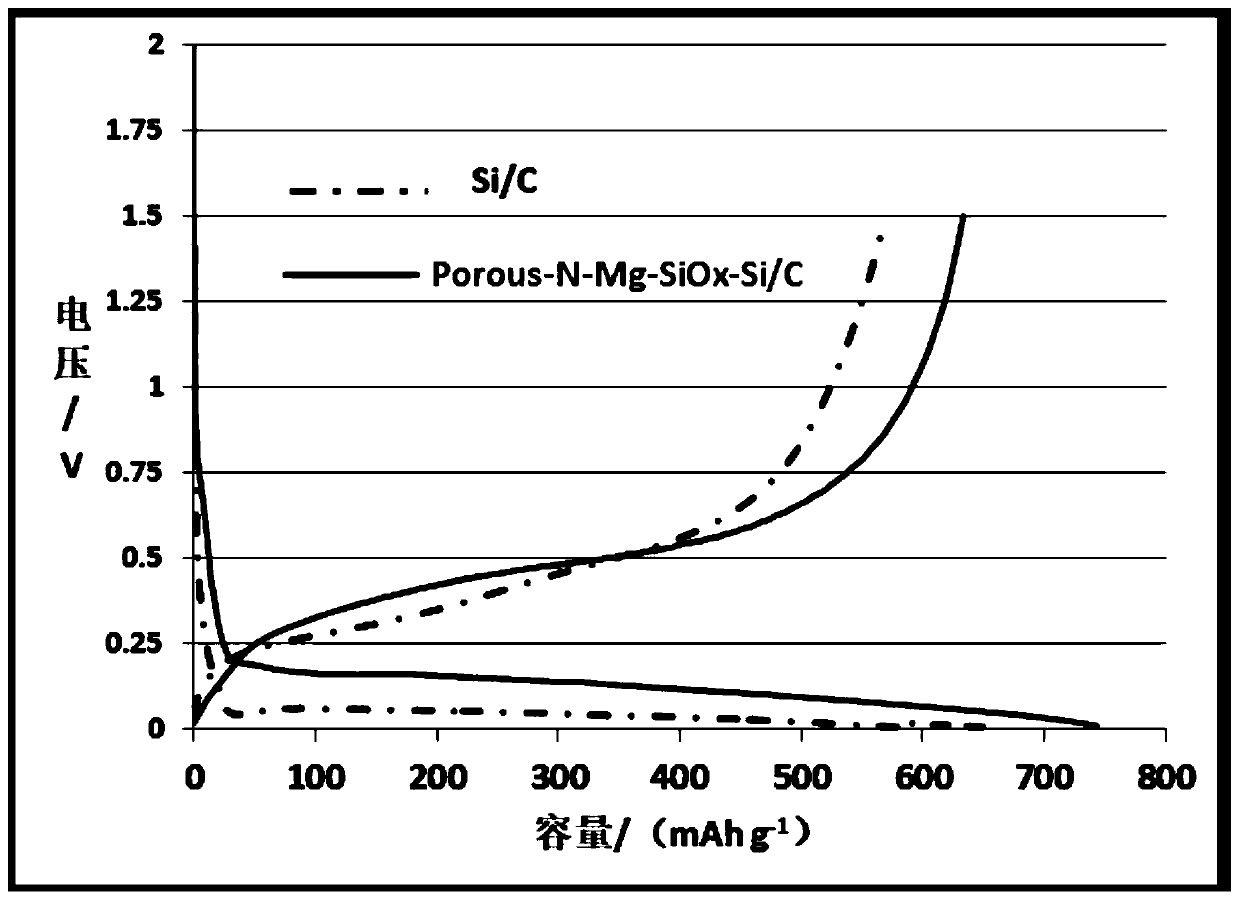

A porous silicon-based and composite material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of ineffective silicon volume expansion, excessive polarization, and low safety, and achieve improved electron conductivity, The effect of suppressing volume expansion and enhancing operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

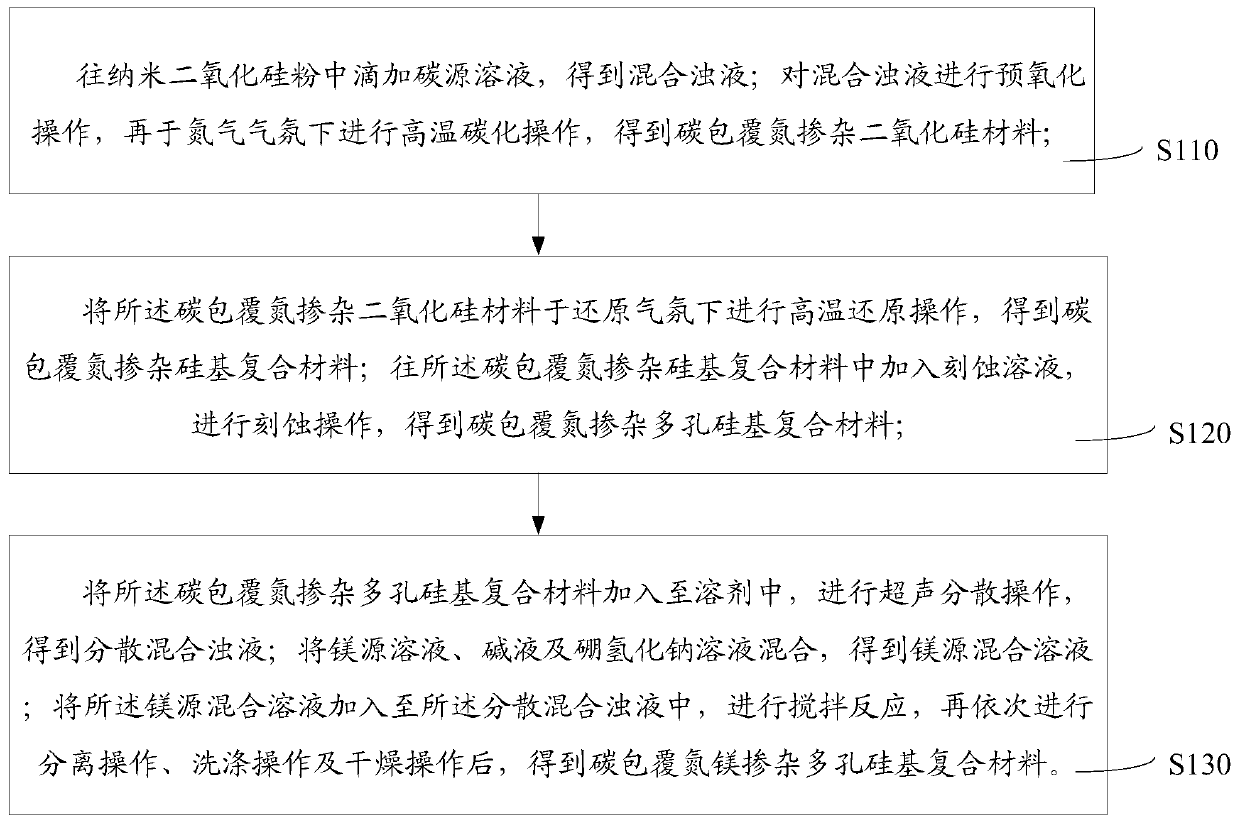

[0030] For an implementation, see figure 1 , a method for preparing a carbon-coated nitrogen-magnesium-doped porous silicon-based composite material, comprising the following steps:

[0031] S110, adding the carbon source solution dropwise into the nano-silica powder to obtain a mixed turbid liquid; performing a pre-oxidation operation on the mixed turbid liquid, and then performing a high-temperature carbonization operation under a nitrogen atmosphere to obtain carbon-coated nitrogen-doped silica Material;

[0032] S120, performing a high-temperature reduction operation on the carbon-coated nitrogen-doped silicon dioxide material in a reducing atmosphere to obtain a carbon-coated nitrogen-doped silicon-based composite material; adding the carbon-coated nitrogen-doped silicon-based composite material Adding an etching solution and performing an etching operation to obtain a carbon-coated nitrogen-doped porous silicon-based composite material;

[0033] S130, adding the carbon...

Embodiment 1

[0056] Tetraethyl orthosilicate, cetyltrimethylammonium bromide and sodium hydroxide are mixed, stirred and reacted to obtain nano-silica gel, and then separated, washed and dried in sequence to obtain 20nm ~ 50nm nano-silica powder.

[0057] The carbon source solution is obtained by mixing a sodium lignosulfonate solution with a solid content of 15% and a polyacrylonitrile solution with a solid content of 15%.

[0058] Put the nano-silica powder into the corundum porcelain boat, then drop the carbon source solution, let it stand for 2 hours to mix the two fully, and get the mixed turbid solution; pre-oxidize the mixed turbid solution in the air at 180°C and 240°C respectively Operate for 3h (heating rate 5°C min -1 ), and then placed in a tube furnace under a nitrogen atmosphere, first at 300 ° C for 30 min (heating rate 5 ° C min -1 ), and then carbonized at 800°C for 4h to obtain a carbon-coated nitrogen-doped silica material.

[0059]The carbon-coated nitrogen-doped sil...

Embodiment 2

[0062] Tetraethyl orthosilicate, cetyltrimethylammonium bromide and sodium hydroxide are mixed, stirred and reacted to obtain nano-silica gel, and then separated, washed and dried in sequence to obtain 20nm ~ 50nm nano-silica powder.

[0063] The carbon source solution is obtained by mixing a sodium lignosulfonate solution with a solid content of 15% and a polyacrylonitrile solution with a solid content of 15%.

[0064] Put the nano-silica powder into the corundum porcelain boat, then drop the carbon source solution, let it stand for 2 hours to mix the two fully, and get the mixed turbid solution; pre-oxidize the mixed turbid solution in the air at 180°C and 240°C respectively Operate for 3h (heating rate 5°C min -1 ), and then placed in a tube furnace under a nitrogen atmosphere, first at 300 ° C for 30 min (heating rate 5 ° C min -1 ), and then carbonized at 1000°C for 4 hours to obtain a carbon-coated nitrogen-doped silica material.

[0065] The carbon-coated nitrogen-do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com