Ternary cathode material coated with lithium tungstate and preparation method of ternary cathode material

A technology for coating lithium tungstate and positive electrode materials, which is applied to positive electrodes, electrical components, battery electrodes, etc., can solve problems such as potential safety hazards, increase the internal pressure of batteries, etc., and achieve environmental protection, simple operation, and good controllability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

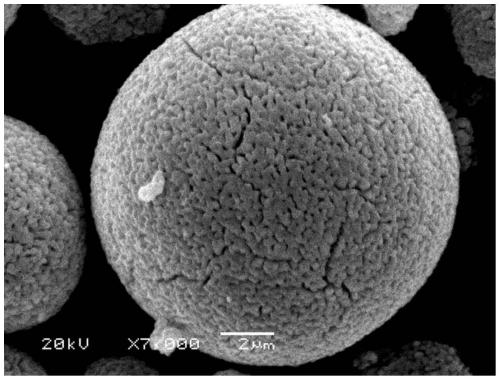

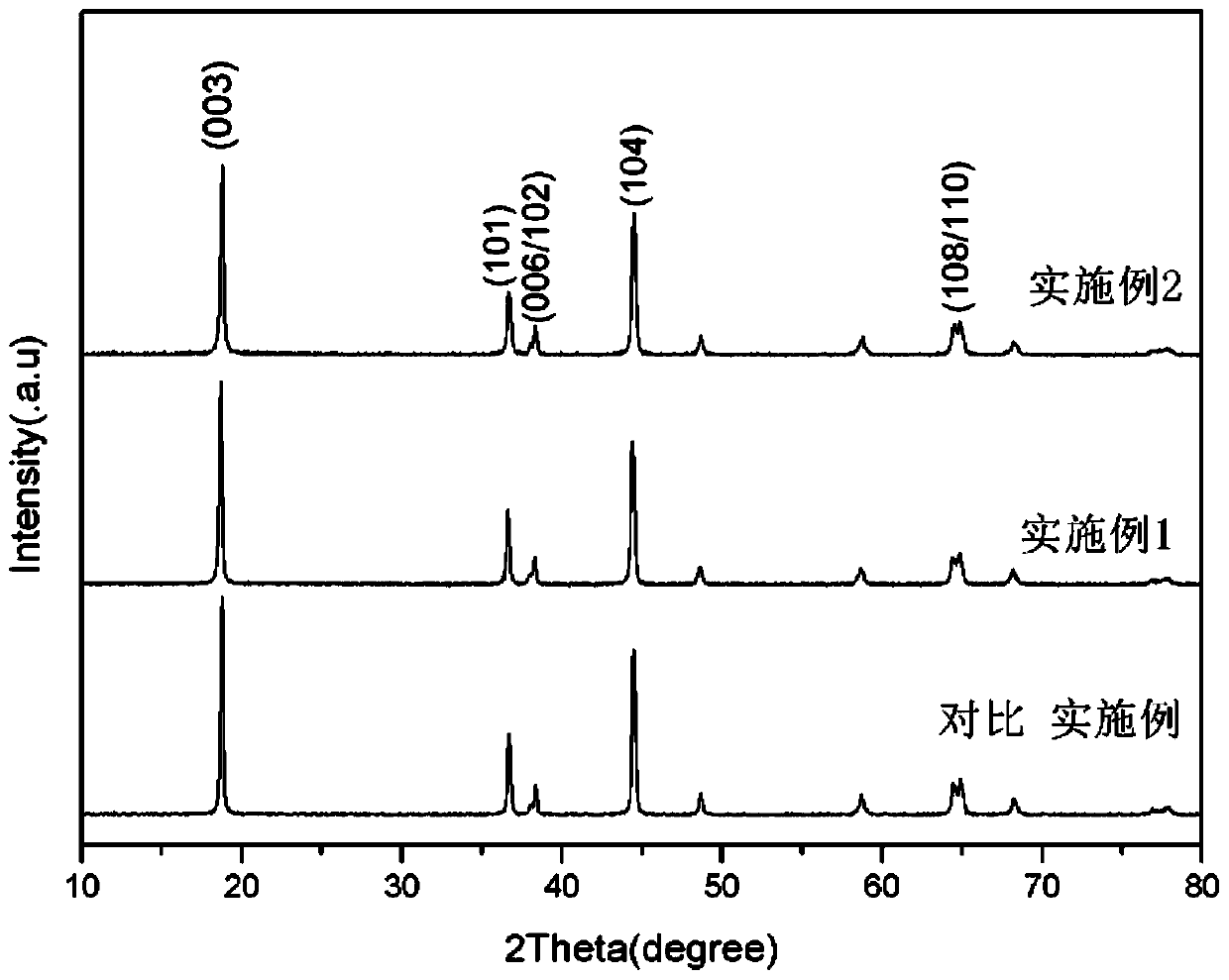

[0035] A ternary cathode material LiNi coated with lithium tungstate 0.8 co 0.1 mn 0.1 o 2 , lithium tungstate and LiNi 0.8 co 0.1 mn 0.1 o 2 The middle transition metal element satisfies the following molar ratio: W / (Ni+Co+Mn)=0.08%.

[0036] The specific steps of the preparation method of the above-mentioned ternary cathode material coated with lithium tungstate are:

[0037] (1) Weigh 5g ternary precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 , put into a tube furnace, and calcined at 750°C for 4h in an air atmosphere.

[0038] (2) Weigh 0.0084g of ammonium paratungstate, dissolve it in 20ml of pure water, and stir until the ammonium paratungstate is completely dissolved.

[0039] (3) Weigh 3 g of the precursor calcined in step (1) and add it to the solution in step (2), stir at room temperature for 10 h, and then stir in an oil bath at 90°C until evaporated to dryness to obtain a solid powder.

[0040](4) Weigh 1.8943g LiOH according to the transition metal to lithium m...

Embodiment 2

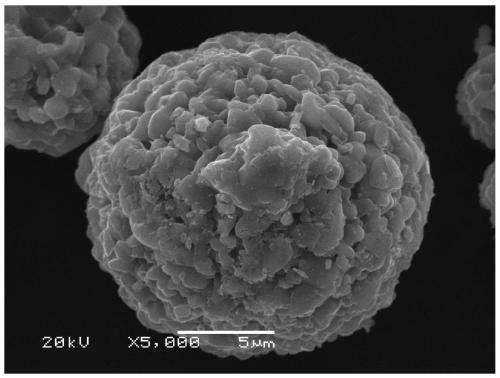

[0044] A ternary cathode material LiNi coated with lithium tungstate 0.8 co 0.1 mn 0.1 o 2 , lithium tungstate and LiNi 0.8 co 0.1 mn 0.1 o 2 Middle transition metal elements satisfy the following molar ratio: W / (Ni+Co+Mn)=0.16%

[0045] The specific steps of the preparation method of the above-mentioned ternary cathode material coated with lithium tungstate are:

[0046] (1) Weigh 5g ternary precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 , put into a tube furnace, and calcined at 750°C for 4h in an air atmosphere.

[0047] (2) Weigh 0.0168g of ammonium paratungstate, dissolve it in 20ml of pure water, and stir until the ammonium paratungstate is completely dissolved.

[0048] (3) Weigh 3 g of the precursor calcined in step (1) and add it to the solution in step (2), stir at room temperature for 10 h, and then stir in an oil bath at 90°C until evaporated to dryness to obtain a solid powder.

[0049] (4) Weigh 1.8943g LiOH according to the transition metal to lithium molar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com