A modifier and its preparation method and use

A modifier and hexagonal phase technology, applied in the field of modifier and its preparation, can solve the problems of limited application, high cost, and graphene is not easy to disperse, and achieve the effect of good interface effect and ensuring continuity and uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

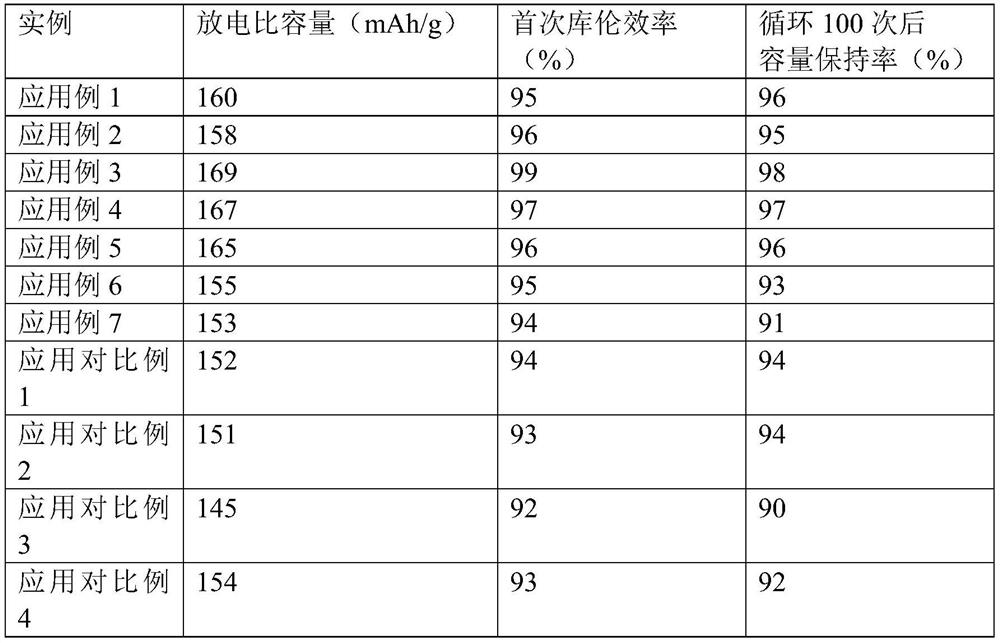

Examples

Embodiment 1

[0056] According to a certain ratio of Li 1.81 h 0.19 Ti 2 o 5 ·H 2 O and hexagonal phase tungsten oxide nanowires were added to the aqueous dispersion of graphene (concentration 1.2mg / mL), so that graphene, Li 1.81 h 0.19 Ti 2 o 5 ·H 2 The mass percentage of O and hexagonal tungsten oxide nanowires is 95%:3%:2%, stirred at a rate of 300r / min for 5h, then ultrasonically treated for 1h, and the ultrasonic power is 500W; the solution after ultrasonic treatment was vacuum-dried at 90°C ; heat-treat the dried product at 700° C. for 0.5 h in an ammonia atmosphere, wherein the flow rate of ammonia gas is 10 sccm, and the product after heat treatment is a positive electrode material modifier.

Embodiment 2

[0058] According to a certain ratio of Li 1.81 h 0.19 Ti 2 o 5 ·3H 2 O and hexagonal phase tungsten oxide nanorods were added to the aqueous dispersion of graphene (concentration 2mg / mL), so that graphene, Li 1.81 h 0.19 Ti 2 o 5 ·3H 2 The mass percentage of O and hexagonal phase tungsten oxide nanorods is 60%:30%:10%, stirred at a rate of 600r / min for 1h, then ultrasonically treated for 4h, and the ultrasonic power is 200W; the solution after ultrasonic treatment was vacuumized at 60°C Drying: heat-treat the dried product at 300° C. for 5 hours in an ammonia gas atmosphere, wherein the flow rate of ammonia gas is 500 sccm, and the product after heat treatment is a positive electrode material modifier.

Embodiment 3

[0060] According to a certain ratio, the phase structure contains H at the same time 2 Ti 3 o 7 , Li 4 Ti 5 o 12 and TiO 2 The compound and hexagonal phase tungsten oxide nanoparticles are added to the graphene water dispersion (concentration 1.5mg / mL), so that the graphene and the phase structure simultaneously contain H 2 Ti 3 o 7 , Li 4 Ti 5 o 12 and TiO 2 The compound, the mass percentage of hexagonal tungsten oxide nanoparticles is 70%: 25%: 5%, stirred at a rate of 1000r / min for 3h, then ultrasonically treated for 3h, with ultrasonic power of 400W, and the solution after ultrasonic treatment was heated at 80°C Vacuum drying; the dried product was heat-treated at 500° C. for 3 hours in an ammonia atmosphere, wherein the flow rate of ammonia gas was 400 sccm, and the product after heat treatment was a positive electrode material modifier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com