Alkaline molecular sieve supported catalyst and preparation method and application thereof

A catalyst and molecular sieve technology, applied in molecular sieve catalyst, catalyst activation/preparation, reductive alkylation preparation, etc., can solve the problems of high price, dependence on imports, high toxicity of adiponitrile, etc., to achieve easy operation and meet industrial application requirements , excellent selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

[0053] The preparation of embodiment 1-10 basic molecular sieve

[0054] Step 1): dissolving an alkali metal salt in water to obtain a precursor solution with a concentration of 0.2-0.6 mol / L, the alkali metal salt being selected from one of potassium nitrate, rubidium nitrate, and cesium nitrate;

[0055] Step 2): Weighing 30g molecular sieves, the molecular sieves are selected from one of NaX, NaY, KL, and NaBeta molecular sieves;

[0056] Step 3) According to the solid-to-liquid ratio of 10:1, use the alkali metal ion precursor solution in step 1) to carry out ion exchange on the molecular sieve weighed in step 2), exchange at 80°C for 4 hours, suction filter and wash 1. After drying, the obtained solid is roasted at 550° C. in a muffle furnace for 6 hours;

[0057] Step 4) Change the object of ion exchange in step 3) from the molecular sieve weighed in step 2) to the molecular sieve obtained after roasting, repeat step 3) twice to obtain a basic molecular sieve sample, an...

Embodiment 11-10

[0062] The preparation of the metal catalyst supported by the basic molecular sieve of embodiment 11-10

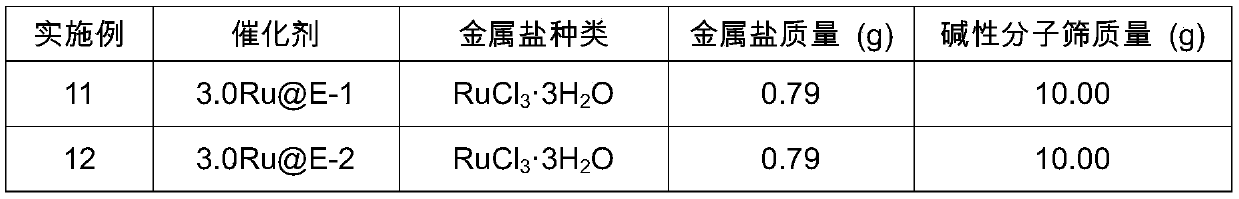

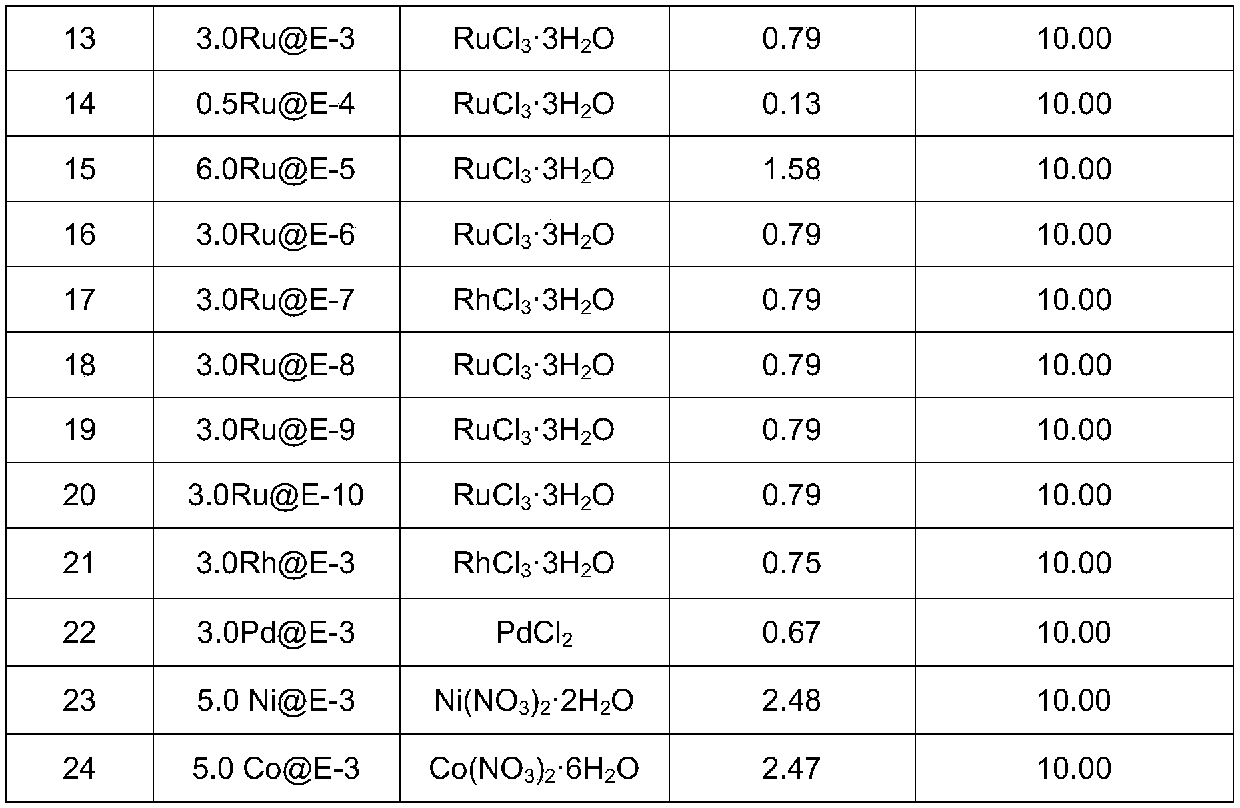

[0063] Dissolve a certain amount of metal salt solution in water, and set the volume to 12mL. Take 10g of basic molecular sieve and use the equal volume impregnation method to load metal elements on the basic molecular sieve, dry it in an oven at 100°C for 12h, and then place it in a muffler at 500°C. Roasting in the furnace for 4h. The types and qualities of carriers and metal salts are shown in Table 2.

[0064] Table 2 Preparation parameters of basic molecular sieve supported metal catalysts

[0065]

[0066]

[0067] Among them, in the catalyst nA@B, A represents the transition metal, B represents the basic molecular sieve, and n represents the mass loading of the transition metal.

Embodiment 25-38

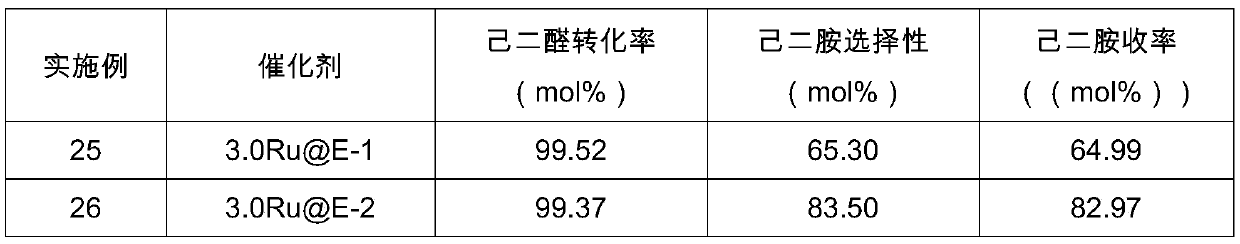

[0068] The reaction performance evaluation of the metal catalyst supported by the basic molecular sieve of embodiment 25-38

[0069] Pack 2.0g of the above-mentioned catalyst in a stainless steel fixed-bed reactor with an inner diameter of 10m and a length of 300mm. Both ends of the catalyst are filled with quartz sand. First, a reducing gas is introduced at a flow rate of 30mL / min, and the catalyst is reduced at 400°C for 4 hours. , wherein the reducing gas consists of H 2 / N 2 Composition by volume ratio 1 / 4.

[0070] After the reduction, the temperature of the reactor was lowered to 130°C, the reaction pressure was raised to 6.0Mpa, and H 2 , liquid ammonia and adipaldehyde for reductive amination reaction, wherein liquid ammonia and adipaldehyde are respectively injected into the reactor through a high-pressure micro-feed pump, and the mass space velocity of adipaldehyde is 1.0h -1 , H 2 :NH 3 : The mol ratio=15:30:1 of adipaldehyde, reaction 10h sampling analysis, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com