Preparation method of protein peptide copper chelate suitable for ruminants

A copper chelate and ruminant technology, applied in the field of preparation of protein peptide copper chelate, can solve problems such as low absorption and utilization rate, and achieve the effects of high production efficiency, simple process flow and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

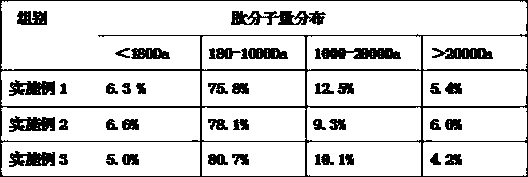

Examples

Embodiment 1

[0018] (1) Preparation of protein solution: Weigh 100 kg of soybean protein isolate powder (crude protein content is 92%), add 800 kg of water, stir evenly, and obtain protein solution;

[0019] (2) Enzymolysis: adjust the pH value of the protein solution to 8.0, add 1.5 kg of protease, and enzymolyze at 55°C for 8 hours, then raise the temperature of the enzymolysis solution to 85°C to inactivate the enzyme for 10 minutes to obtain the enzymolysis solution;

[0020] (3) Ultrafiltration: The enzymatic hydrolysis solution is subjected to ultrafiltration through an ultrafiltration membrane device with a molecular weight cut-off of 3000Da, and the permeate is collected to obtain a protein peptide solution;

[0021] (4) Chelation reaction: Add 5 kg of copper sulfate to the protein peptide solution, adjust the pH value of the solution to 5.5 under constant stirring, raise the temperature to 80°C, and keep it warm for 2 hours to obtain the protein peptide copper chelation reaction so...

Embodiment 2

[0024] (1) Preparation of protein solution: Weigh 100 kg of soybean protein isolate powder (crude protein content is 90%), add 550 kg of water, stir evenly, and obtain protein solution;

[0025] (2) Enzymolysis: adjust the pH value of the protein solution to 8.5, add 1.8 kg of protease, and enzymolyze at 52°C for 5 hours, then raise the temperature of the enzymolysis solution to 85°C to inactivate the enzyme for 10 minutes to obtain the enzymolysis solution;

[0026] (3) Ultrafiltration: The enzymatic hydrolysis solution is subjected to ultrafiltration through an ultrafiltration membrane device with a molecular weight cut-off of 3000Da, and the permeate is collected to obtain a protein peptide solution;

[0027] (4) Chelation reaction: Add 8 kg of copper sulfate to the protein peptide solution, adjust the pH value of the solution to 5.8 under constant stirring, raise the temperature to 90°C, and keep it warm for 3 hours to obtain the protein peptide copper chelation reaction so...

Embodiment 3

[0030] (1) Preparation of protein solution: Weigh 100 kg of soybean protein isolate powder (crude protein content is 91%), add 600 kg of water, stir evenly, and obtain protein solution;

[0031] (2) Enzymolysis: adjust the pH value of the protein solution to 8.2, add 1.62 kg of protease, and enzymolyze at 50°C for 6 hours, then raise the temperature of the enzymolysis solution to 85°C to inactivate the enzyme for 10 minutes to obtain the enzymolysis solution;

[0032] (3) Ultrafiltration: The enzymatic hydrolysis solution is subjected to ultrafiltration through an ultrafiltration membrane device with a molecular weight cut-off of 3000Da, and the permeate is collected to obtain the ultrafiltration permeate;

[0033] (4) Chelation reaction: add 10 kg of copper sulfate to the protein peptide solution, adjust the pH value of the solution to 6.0 under constant stirring, raise the temperature to 85°C, and keep it warm for 2.5 hours to obtain the protein peptide copper chelation react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com