Microcapsule suspension-suspending agent containing lambda-cyhalothrin and clothianidin and preparation method thereof

A technology of high-efficiency cyhalothrin and microcapsule suspension, which is applied in the fields of botanical equipment and methods, insecticides, biocides, etc., can solve the problems of poor insecticidal effect, etc. effect of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

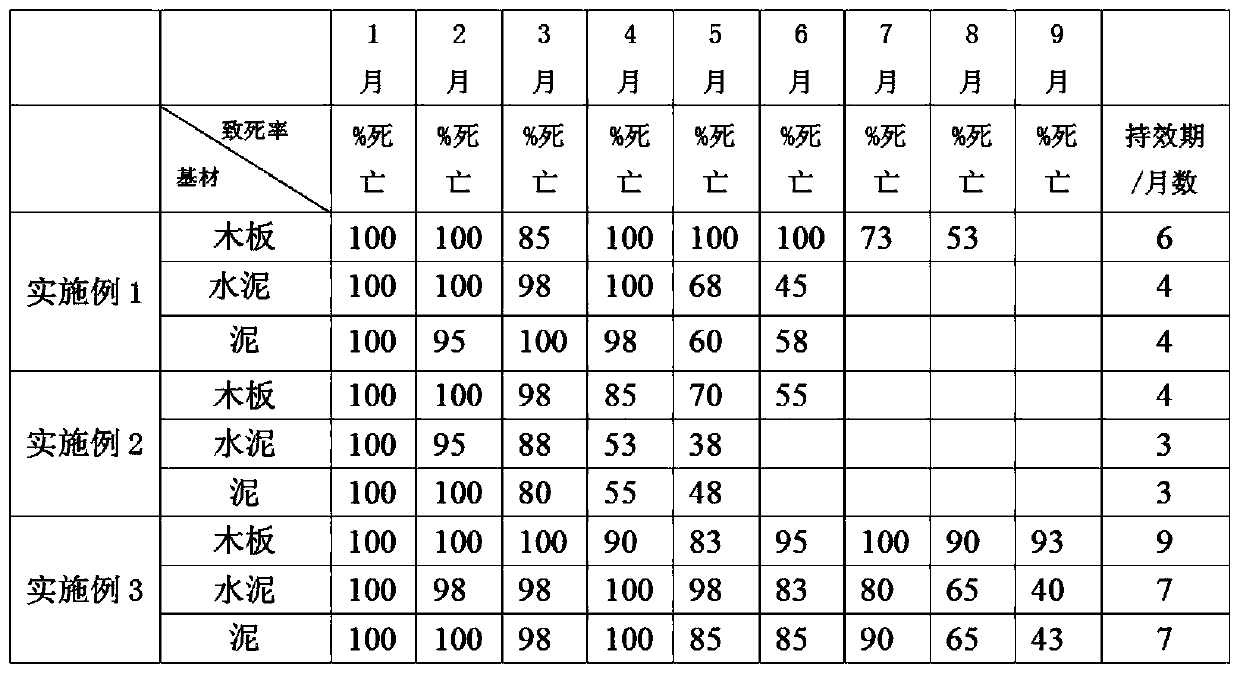

Examples

Embodiment 1

[0039] A kind of microcapsule suspension-suspension preparation method containing lambda-cyhalothrin and clothianidin, its specific steps are:

[0040] (1). Weigh raw materials according to the lower ratio, neonicotinoid insecticide 1-40%, lambda-cyhalothrin 1-10%, dispersant 1-10%, wetting agent 2-10%, disinfectant Foaming agent 0.1-1%, thickener 0.1-2%, antifreeze agent 0.1-8%, emulsifier 0.5%-5%, deionized water to 100%, neonicotinoid insecticide choose clothianidin, Dissolve clothianidin with a dispersant and a wetting agent, then add an emulsifier, stir evenly, and obtain an oil phase;

[0041] (2). Adding a dispersant in water to obtain an aqueous phase;

[0042] (3). Put the water phase prepared in (2) into the reactor, add the oil phase obtained in (1) to the water phase in (2), and stir while adding to form an oil-in-water emulsion liquid;

[0043] (4). While stirring, add an emulsifier into the reaction kettle containing the emulsion, and then heat it at a tempera...

Embodiment 2

[0051] A kind of microcapsule suspension-suspension preparation method containing lambda-cyhalothrin and clothianidin, its specific steps are:

[0052] (1). Weigh the raw materials according to the lower ratio, clothianidin and imidacloprid mixture 40%, lambda-cyhalothrin 5%, dispersant 5%, wetting agent 8%, defoamer 0.5%, thickener 1.5% %, antifreeze 6%, emulsifier 4%, deionized water to 100%, clothianidin and imidacloprid are mixed with a dispersant and a wetting agent to dissolve, then add an emulsifier, stir evenly, and obtain an oil phase;

[0053] (2). Adding a dispersant in water to obtain an aqueous phase;

[0054] (3). Put the water phase prepared in (2) into the reactor, add the oil phase obtained in (1) to the water phase in (2), and stir while adding to form an oil-in-water emulsion liquid;

[0055] (4). Under the condition of stirring, add an emulsifier into the reaction kettle containing the emulsion, and then heat it at a heating temperature of 30-70° C., heat...

Embodiment 3

[0063] One, the preparation of 480g / L clothianidin suspension concentrate (SC) preparation:

[0064] 43.73g clothianidin technical substance (98%w / w), dispersant polycarboxylate 4g, wetting agent block polyether 2g, organosilicon defoamer 0.2g and deionized water 45.57g were sheared Mix and disperse evenly, and grind the obtained premix in a sand mill for a certain period of time by wet grinding until the particle size D90 is 5 μm; add 0.5 g of xanthan gum thickener to the ground premix , Antifreeze agent ethylene glycol 3g and preservative Cathone 1g were stirred and dispersed to obtain 480g / L clothianidin suspension concentrate (SC).

[0065] Two, the preparation of 300g / L lambda-cyhalothrin microcapsule suspension (CS) preparation:

[0066] Add 28.61 g of lambda-cyhalothrin technical material (97.1% w / w pirimiphos-methyl) and 3 g of diphenylmethane diisocyanate to 10 g of mineral spirits S-150 and mix uniformly to form an oil phase.

[0067] The water phase includes 27.19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com