Phellinus igniarius phenol extract with blood sugar reducing activity and preparation and application of phellinus igniarius phenol extract

A technology of Phellinol and extract, applied in the field of Phellinol extract, can solve the problem of high cost, and achieve the effect of low cost, high preparation efficiency and good blood sugar lowering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

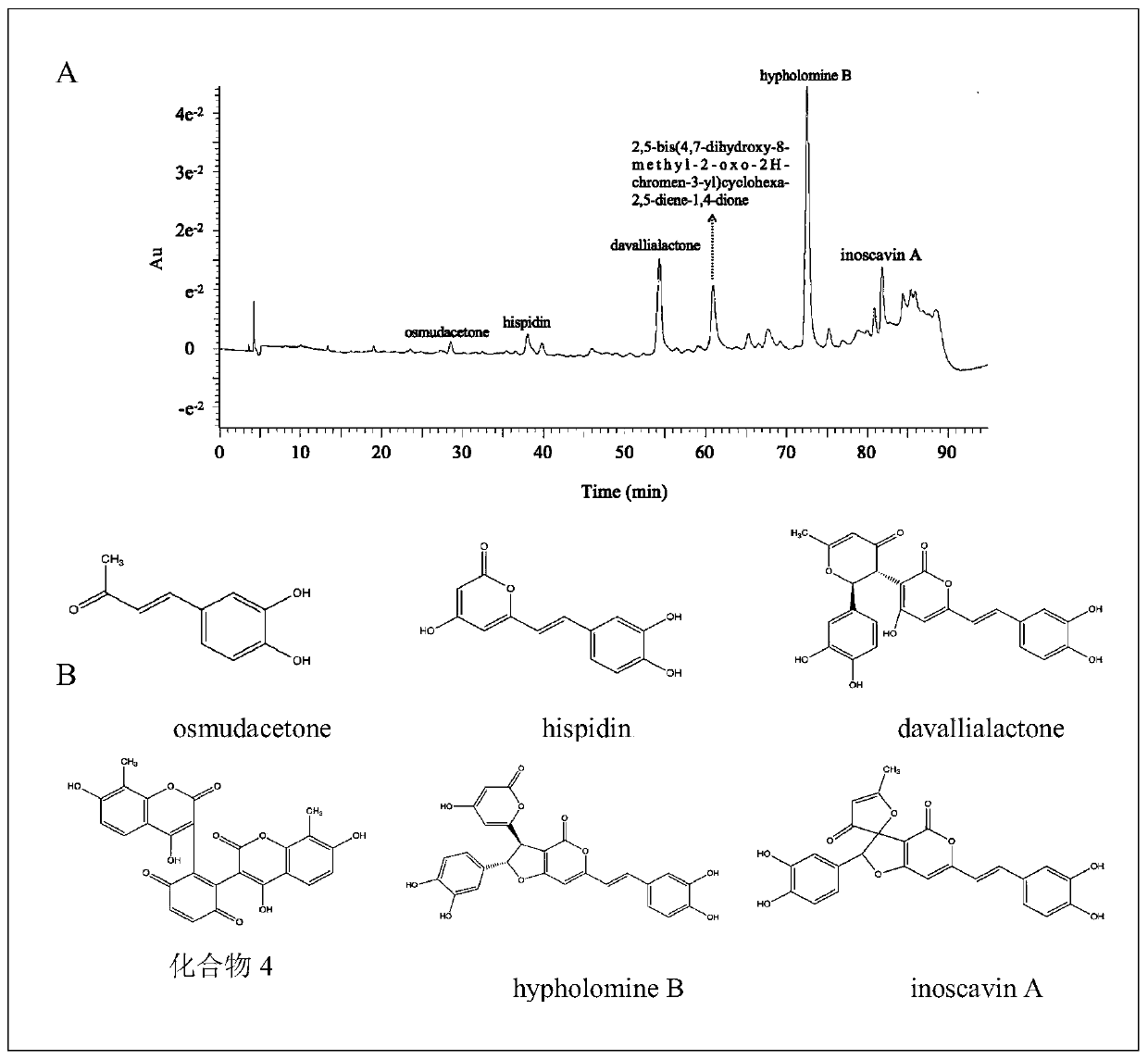

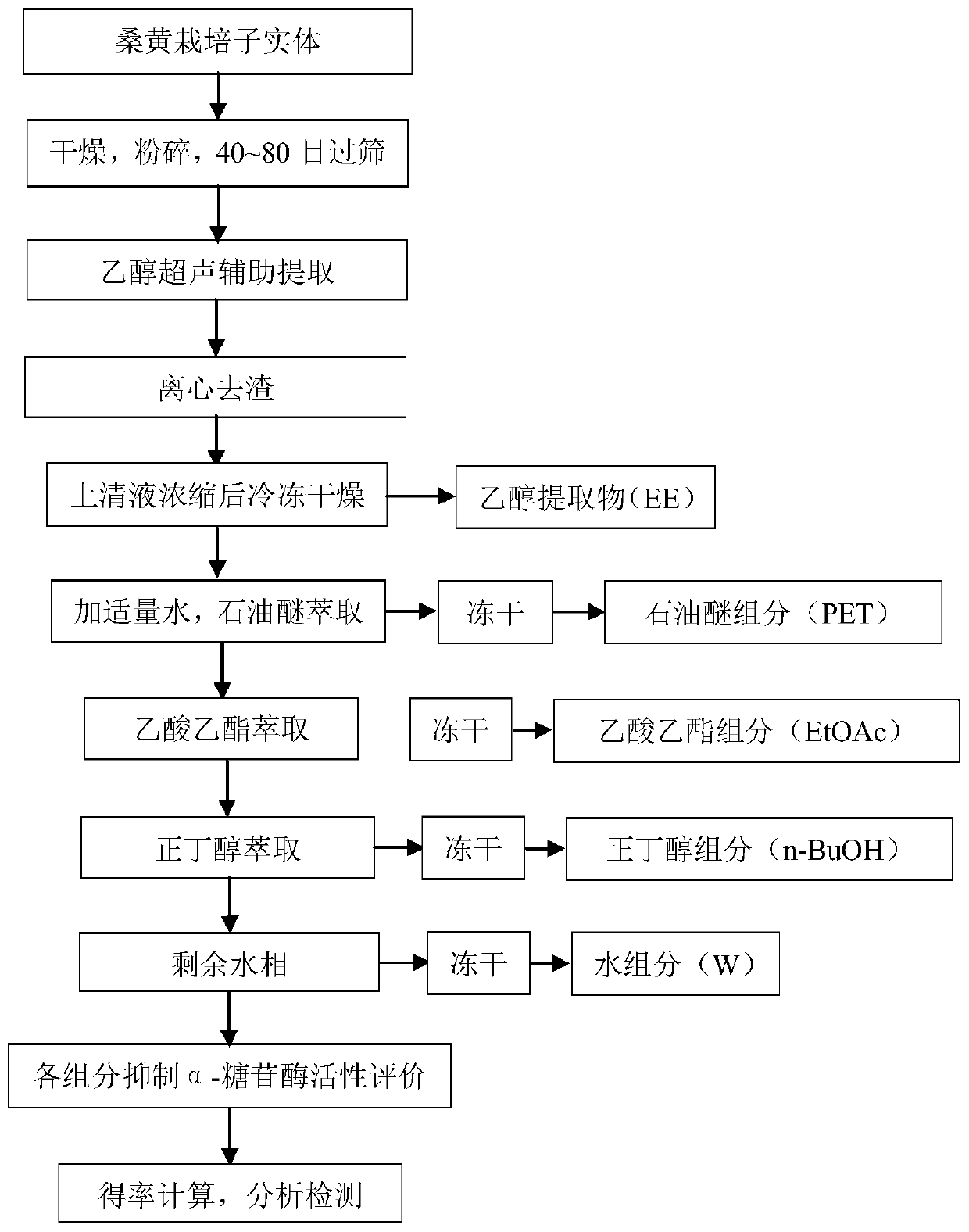

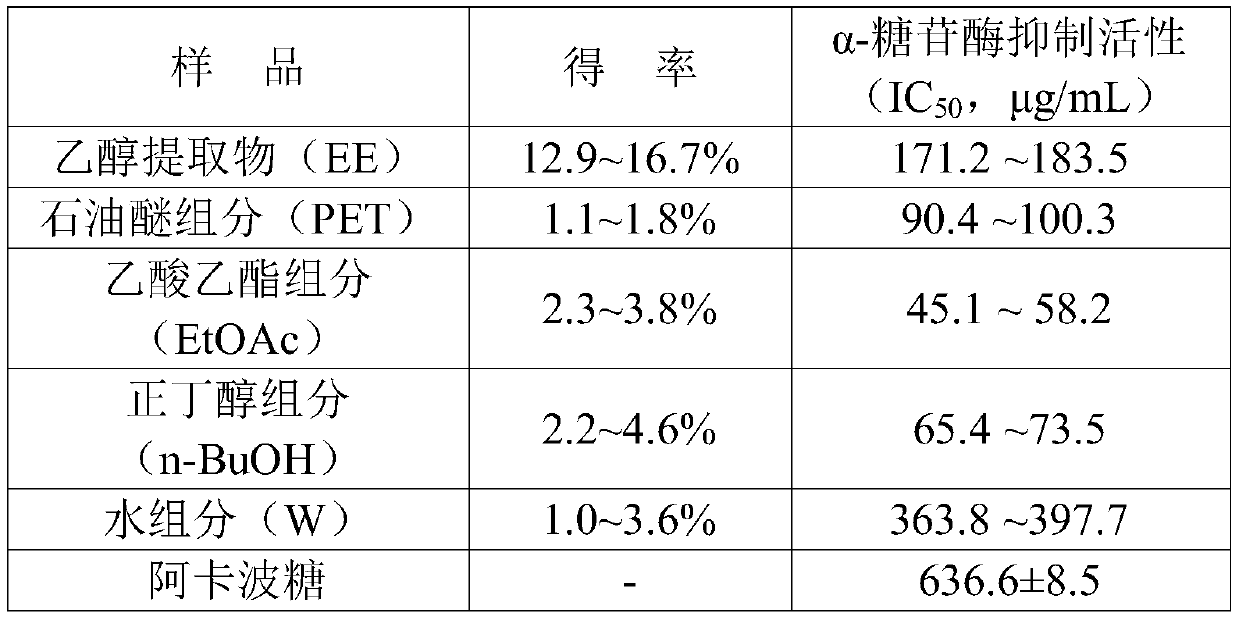

[0063] See the process flow figure 2 , Phellinus japonica cultivation fruiting body → vacuum drying at 45°C → crush and sieve to 50 mesh → weigh 50g and add 1:10 (solid-to-liquid ratio, w / w), 60% (w / w) ethanol aqueous solution → ultrasonic assisted extraction, The extraction power is 80W, the time is 20in, and the number of extractions is 3 times→5000r / min centrifuge to remove residue→combine the supernatant liquid→rotary evaporation, 50℃, vacuum degree 0.1Mpa, concentrate to 1 / 5 of the original volume→freeze drying→ Phellinus ethanol extract (EE) → add 200mL pure water for ultrasonic suspension, add the same volume of petroleum ether to extract twice, and collect petroleum ether extract (PET) → add the remaining phase to the same volume of ethyl acetate to extract twice, combine Collect the ethyl acetate extract phase (EtOAc) → add the same volume of n-butanol to the remaining phase and extract twice, combine and collect the n-butanol extract phase (n-BuOH) → collect the abo...

Embodiment 2

[0066] Cultivate the fruit body of Phellinus japonica → vacuum dry at 45°C → crush and sieve to 50 mesh → weigh 50g and add 1:20 (solid-to-liquid ratio, w / w), 70% (w / w) ethanol aqueous solution → ultrasonic assisted extraction, extract The power is 90W, the time is 30min, and the number of extractions is 3 times→5000r / min centrifuge to remove residue→combine the supernatant liquid→rotary evaporation, 50℃, vacuum degree 0.1Mpa, concentrate to 1 / 5 of the original volume→freeze drying→mulberry Yellow ethanol extract (EE) → add 300mL pure water for ultrasonic suspension, add the same volume of petroleum ether to extract twice, and collect petroleum ether extract (PET) → add the remaining phase to the same volume of ethyl acetate to extract twice, combine and collect Ethyl acetate extraction phase (EtOAc) → add the same volume of n-butanol to the remaining phase and extract twice, combine and collect the n-butanol extraction phase (n-BuOH) → collect the above EtOAc phase → concentra...

Embodiment 3

[0069]Cultivate the fruit body of Phellinus japonica → vacuum dry at 45°C → crush and sieve to 60 mesh → weigh 50g and add 1:30 (solid-to-liquid ratio, w / w), 80% (w / w) ethanol aqueous solution → ultrasonic assisted extraction, extract The power is 100W, the time is 30min, and the number of extractions is 3 times→5000r / min centrifuge to remove slag→combine the supernatant liquid→rotary evaporation, 50℃, vacuum degree 0.05Mpa, concentrate to 1 / 5 of the original volume→freeze drying→mulberry Yellow ethanol extract (EE) → add 300mL pure water for ultrasonic suspension, add the same volume of petroleum ether for extraction 3 times, and collect petroleum ether extract (PET) → add the remaining phase to the same volume of ethyl acetate for extraction 3 times, combine and collect Ethyl acetate extraction phase (EtOAc) → add the same volume of n-butanol to the remaining phase and extract 3 times, combine and collect the n-butanol extraction phase (n-BuOH) → collect the above EtOAc phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com