Preparation method of phenolic resin reinforced three-dimensional graphene aerogel

A technology of graphene airgel and phenolic resin, which is applied in the direction of airgel preparation, chemical instruments and methods, colloid chemistry, etc., can solve problems such as shedding, weak interaction, affecting electrical properties, stability and mechanical properties, etc. Achieve the effect of improving mechanical strength, simple and easy preparation method, and realizing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

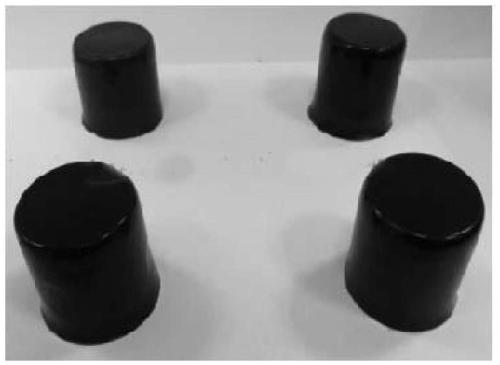

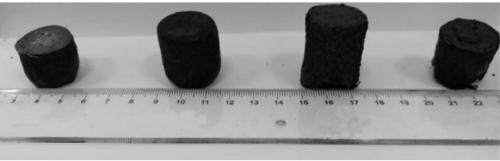

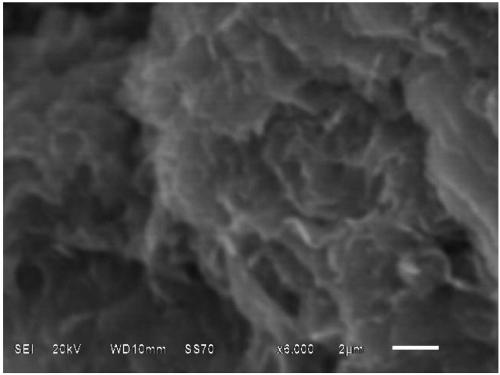

[0032] As a detailed example of the preparation method of a phenolic resin-reinforced three-dimensional graphene airgel, the specific steps include: (1) ultrasonically dispersing graphene oxide in deionized water to obtain an aqueous solution of graphene oxide; (2) then phenolic , cross-linking agent and curing accelerator, aldehydes and phenolic reaction catalysts are sequentially added to the graphene oxide dispersion in (1) according to a certain proportion, after stirring evenly, the mixed solution is transferred to a reaction kettle, and hydrothermal treatment is carried out at a certain temperature Reaction; (3) after reacting for a period of time, the (2) reactor is cooled to room temperature, and the hydrogel after the reaction is taken out, and unreacted phenol and aldehyde monomers are removed by repeated washing with deionized water; (4) the (3) ) hydrogels were freeze-dried to obtain phenolic resin-reinforced three-dimensional graphene aerogels.

[0033] The three-...

Embodiment 1

[0036] First, graphene oxide was prepared by the improved Hummers method, and a 4 mg / ml graphene oxide aqueous solution was prepared by ultrasonic and mechanical stirring, and then phenol (62 mg) and formaldehyde (18 mg) were added in a molar ratio of 1:1 Concentration is in the graphene oxide dispersion (160ml) of 5mg / ml, then add the potassium hydroxide of 10% of the total mass of phenolic substances and aldehydes substance, ultrasonic and stir evenly and then transfer to the reaction kettle. React the reaction kettle with the mixed solution at 160° C. for 8 hours to obtain graphene hydrogel reinforced with phenolic resin. After the hydrogel was washed with deionized water and freeze-dried for 48 h, a three-dimensional graphene airgel reinforced with phenolic resin was obtained. Then put the three-dimensional graphene airgel reinforced by phenolic resin into a quartz tube, under the protection of 200sccm argon, heat up to 800°C, anneal for 2 hours, and obtain the three-dimen...

Embodiment 2

[0038] First, graphene oxide was prepared by the improved Hummers method, and a 4 mg / ml graphene oxide aqueous solution was prepared by ultrasonic and mechanical stirring, and then phenol (62 mg) and formaldehyde (18 mg) were added in a molar ratio of 1:1 Concentration is in the graphene oxide dispersion liquid (160ml) of 5mg / ml, then add the potassium hydroxide of 10% of the total mass of phenolic substances and aldehydes substance, add the hexamethylenetetramine of 10mg and 5mg after stirring for 30min Benzenesulfonyl chloride, ultrasonic and stirred evenly, then transferred to the reaction kettle. React the reaction kettle with the mixed solution at 160° C. for 8 hours to obtain graphene hydrogel reinforced with phenolic resin. After the hydrogel was washed with deionized water and freeze-dried for 48 h, a three-dimensional graphene airgel reinforced with phenolic resin was obtained. Then put the three-dimensional graphene airgel reinforced by phenolic resin into a quartz ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com