Preparation method of tert-butyl acrylate

A technology of tert-butyl acrylate and acrylic acid, applied in the field of preparation of tert-butyl acrylate, can solve the problems of complex polymerization inhibitor and high reaction temperature, and achieve the effects of mild reaction, simple process and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

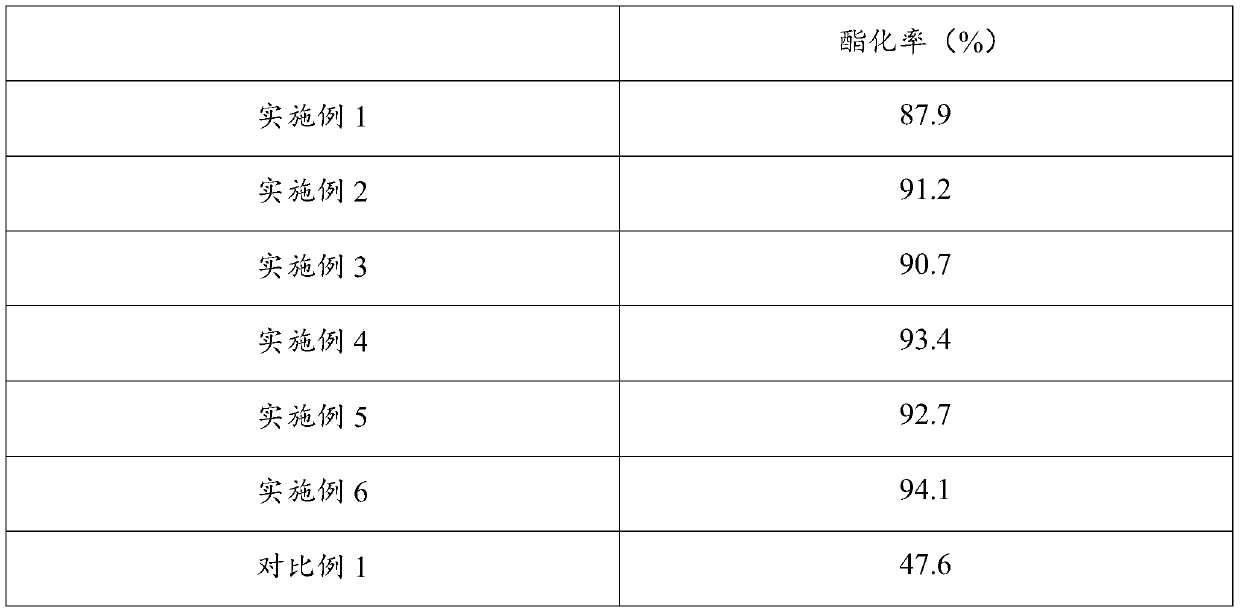

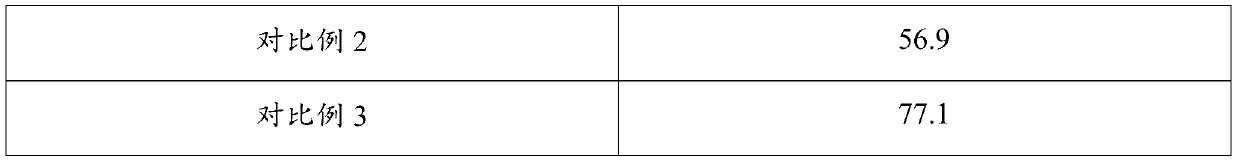

Examples

Embodiment 1

[0022] Put acrylic acid, catalyst, polymerization inhibitor and isobutylene into the reactor, under the conditions of temperature 30°C and pressure 1MPa, esterification reaction occurs at the volume space velocity of isobutylene 1.0 / h to synthesize tert-butyl acrylate;

[0023] Wherein, the molar ratio of acrylic acid, polymerization inhibitor and isobutylene is 1:0.1:0.5, the catalyst is a mixture of sulfonic acid type cation exchange resin and p-toluenesulfonic acid, the mass ratio of the two is 3:1, the total mass of the catalyst It is 10% of the mass of acrylic acid; the polymerization inhibitor is a mixture of tert-butylcatechol and tert-butanol, and the mass ratio of the two is 1:1.

Embodiment 2

[0025] Put acrylic acid, catalyst, polymerization inhibitor and isobutylene into the reactor, under the conditions of temperature 30°C and pressure 1MPa, esterification reaction occurs at the volume space velocity of isobutylene 1.0 / h to synthesize tert-butyl acrylate;

[0026] Wherein, the molar ratio of acrylic acid, polymerization inhibitor and isobutylene is 1:0.1:0.5, the catalyst is a mixture of sulfonic acid modified SBA-15 mesoporous molecular sieve and p-toluenesulfonic acid, the mass ratio of the two is 3:1, The total mass of the catalyst is 10% of the mass of acrylic acid; the polymerization inhibitor is a mixture of tert-butylcatechol and tert-butanol, and the mass ratio of the two is 1:1.

Embodiment 3

[0028] Put acrylic acid, catalyst, polymerization inhibitor and isobutylene into the reactor, under the conditions of temperature 30°C and pressure 1MPa, esterification reaction occurs at the volume space velocity of isobutylene 1.0 / h to synthesize tert-butyl acrylate;

[0029] Wherein, the molar ratio of acrylic acid, polymerization inhibitor and isobutylene is 1:0.2:0.8, the catalyst is a mixture of sulfonic acid modified SBA-15 mesoporous molecular sieve and p-toluenesulfonic acid, the mass ratio of the two is 3:1, The total mass of the catalyst is 8% of the mass of acrylic acid; the polymerization inhibitor is a mixture of tert-butylcatechol and tert-butanol, and the mass ratio of the two is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com