Photosensitive color-changing low melting point polyester film and preparation method thereof

A low-melting polyester, photochromic technology, applied in the polyester field, can solve the problems of limited activity space of color-changing functional groups, poor stability, many hard segments, etc. The effect of prolonging the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

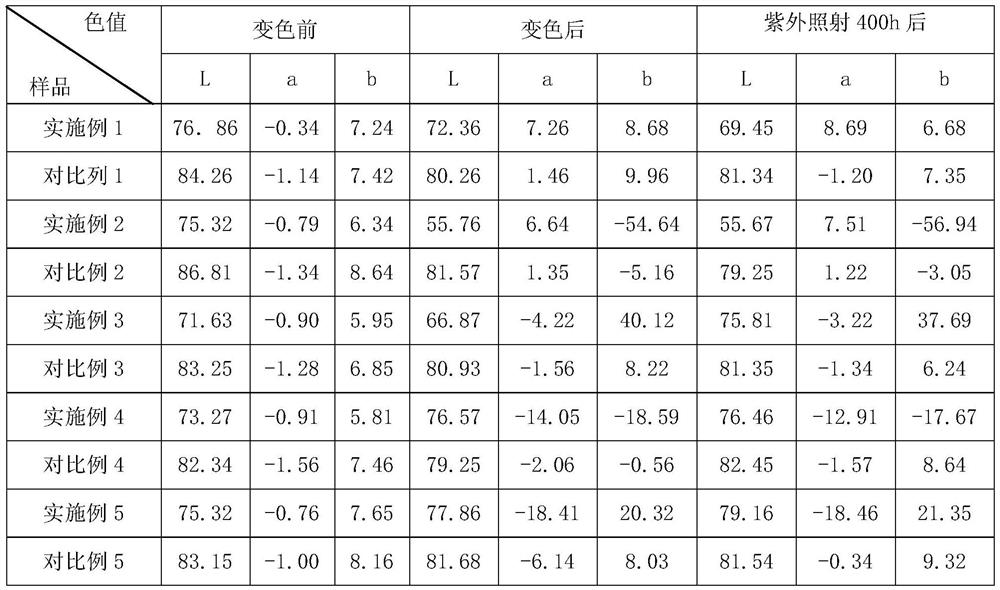

Examples

Embodiment 1

[0031] In a 20L polymerization reactor, successively add 3500 grams of terephthalic acid, 162 grams of adipic acid, 3915 grams of 1,4-butanediol, and adipic acid-based polyester diol with a molecular weight of 500 (Hua Da Chemical Group Co., Ltd. Company brand CMA-1044) 435 grams, tetrabutyl titanate 3.4 grams. Fill the reaction kettle with nitrogen to 0.1MPa, and then discharge it from the rectification column, repeat the replacement 3 times, set the temperature to heat, and carry out the esterification reaction at 180 ° C ~ 230 ° C under normal pressure conditions, esterification 3-4 hours , when the water output reaches 2000-2500mL, add 11.1 grams of cyclohexanol, react for 20 minutes, close the rectification column, open the vacuum system, gradually open the vacuum valve, and transition from low vacuum to high vacuum within 45 minutes. The internal absolute pressure is reduced to below 100Pa, and at the same time, the temperature inside the reactor is raised to 250°C~260°C...

Embodiment 2

[0034]In a 20L polymerization reactor, 3500 grams of terephthalic acid, 252.9 grams of succinic acid, 2131.5 grams of ethylene glycol, 468.5 grams of polycarbonate diol with a molecular weight of 1000, and 0.24 grams of antimony acetate were successively added. Fill the reaction kettle with nitrogen to 0.1MPa, and then discharge it from the rectification column, repeat the replacement 3 times, set the temperature to heat, and carry out the esterification reaction at 260 ° C ~ 280 ° C and a pressure of 0.2 MPa, esterification 2-2.5 When the water output reaches 1200-1400mL, release the pressure, add 20.6 grams of isoamyl alcohol, react at normal pressure for 20 minutes, close the rectification column, open the vacuum system, gradually open the vacuum valve, and transition from low vacuum to vacuum within 45 minutes. High vacuum, the absolute pressure in the reactor is reduced to below 100Pa, at the same time, the temperature in the reactor is raised to 280 ℃ ~ 300 ℃, and the pol...

Embodiment 3

[0037] In a 20L polymerization reactor, add 3,000 grams of terephthalic acid, 596.9 grams of glutaric acid, 4,670.4 grams of 1,4-butanediol, 1,129.5 grams of polyε-caprolactone diol with a molecular weight of 500, tetra-titanate Butyl ester 4.2 g. Fill the reaction kettle with nitrogen to 0.1MPa, and then discharge it from the rectification column, repeat the replacement 3 times, set the temperature to heat, and carry out the esterification reaction at 180 ° C ~ 230 ° C under normal pressure conditions, esterification 3-4 hours , when the water output reaches 2000-2500mL, add 5.3 grams of n-heptanol, react for 20 minutes, close the rectification column, open the vacuum system, gradually open the vacuum valve, and transition from low vacuum to high vacuum within 45 minutes. The absolute pressure is lowered below 100Pa, and at the same time, the temperature in the reactor is raised to 250°C to 260°C, and the polymerization reaction is carried out under this condition. The polyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com