Nitrogen-doped molybdenum disulfide/carbon nanotube composite material

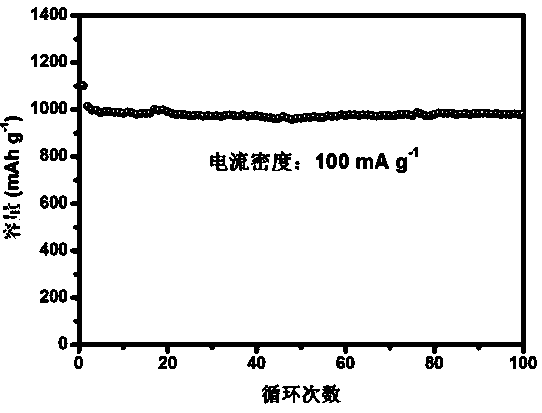

A technology of acidifying carbon nanotubes and molybdenum disulfide, which is applied to electrical components, battery electrodes, circuits, etc., can solve the problems of complicated and time-consuming operations, low nitrogen doping content, and low product utilization, and achieve simplified production processes, The effect of large specific surface area and large specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

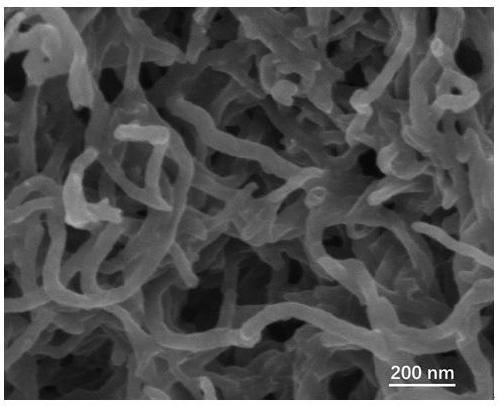

[0036] Preparation of acidified carbon nanotubes: put 1g of carbon nanotubes and 200mL of concentrated sulfuric acid into a three-necked flask, ultrasonically disperse evenly, slowly add 60mL of 70% concentrated nitric acid dropwise, reflux and stir at 60°C for 1h, cool naturally to room temperature, add Dilute with a large amount of deionized water, let it stand for stratification, remove the supernatant, and dialyze the black precipitate at the bottom with deionized water to replace the small molecules in it, so that the surface can be balanced, and a long-term stable and uniform dispersion of carbon nanotubes can be obtained. liquid. The carbon nanotube aqueous dispersion is freeze-dried to obtain acidified carbon nanotube powder, which is placed in a desiccator for subsequent use. Its SEM picture is as follows figure 1 As shown, the structure of one-dimensional carbon nanotubes can be clearly seen, and the walls of carbon nanotubes after acidification treatment are relati...

Embodiment 1

[0039] (1) Weigh 1.0 g of acidified carbon nanotubes and disperse them in 20 mL of 37% formaldehyde aqueous solution, place them in an ultrasonic instrument and disperse evenly, and record them as dispersion liquid A.

[0040] (2) Weigh 3.0g of melamine and 5.0g of ammonium tetrathiomolybdate and add them into 40mL of deionized water, place them in an ultrasonic instrument and ultrasonically disperse evenly, and record it as dispersion liquid B.

[0041] (3) Mix Dispersion A and Dispersion B, raise the temperature of the water bath to 60°C and stir for 10 minutes. Then triethanolamine was added to the reaction solution to adjust the pH value of the reaction solution system to 8.0, and the mixture was uniformly mixed by ultrasonic, then the reaction solution was poured into a high-pressure reactor, and the temperature was raised to 120° C. for 12 hours to react. Suction filtration, vacuum drying to obtain a black solid powder.

Embodiment 2

[0044] (1) Weigh 1.0 g of acidified carbon nanotubes and disperse them in 30 mL of 37% formaldehyde aqueous solution, place them in an ultrasonic instrument and disperse evenly, and record them as dispersion liquid A.

[0045] (2) Weigh 5.0g of melamine and 8.0g of ammonium tetrathiomolybdate and add them into 40mL of deionized water, place them in an ultrasonic instrument and ultrasonically disperse evenly, and record it as dispersion liquid B.

[0046] (3) Mix Dispersion A and Dispersion B, raise the temperature of the water bath to 60°C and stir for 10 minutes. Then triethanolamine was added to the reaction solution to adjust the pH value of the reaction solution system to 8.0, and the mixture was uniformly mixed by ultrasonic, then the reaction solution was poured into a high-pressure reactor, and the temperature was raised to 120° C. for 12 hours to react. Suction filtration, vacuum drying to obtain a black solid powder.

[0047] (4) Put the black solid powder obtained i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com