Efficient subsurface flow constructed wetland system and sewage treatment method thereof

A constructed wetland system and wetland technology, which is applied in the field of high-efficiency subsurface flow constructed wetland systems, can solve the problems that the effluent indicators cannot meet the design standards, shorten the operating life of constructed wetlands, and poorly operate wetlands in winter, so as to improve the biochemical properties of wastewater, Prevention of short-circuit flow and dead water zone, the same effect of pollution load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

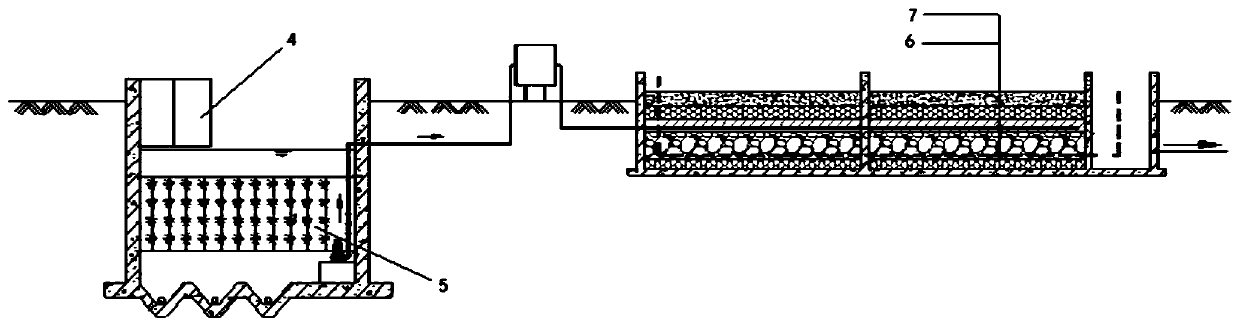

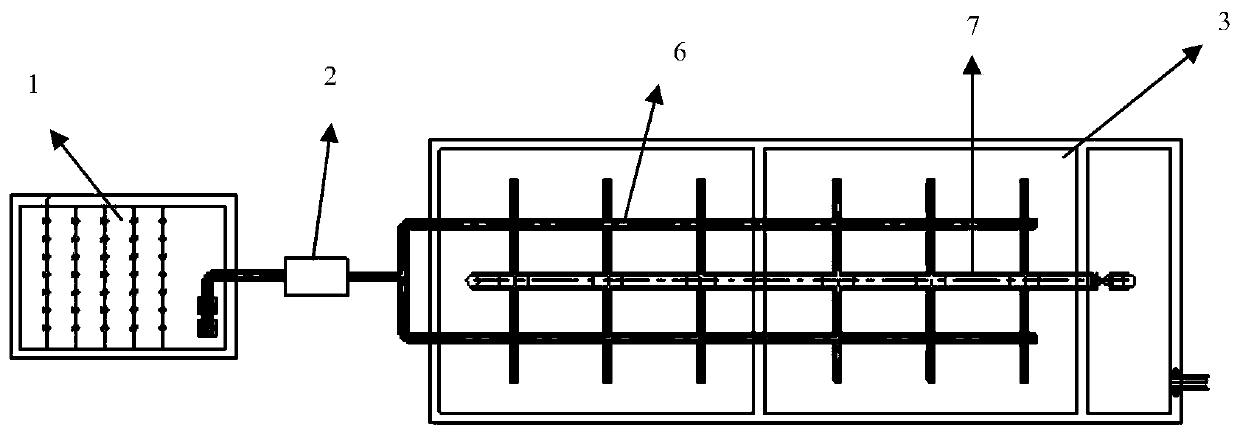

[0037] Such as figure 1 As shown, a high-efficiency subsurface flow constructed wetland system includes a multifunctional combination pool 1 and a wetland unit 3. The sewage first intercepts suspended solids and floating impurities in the multifunctional combination pool, and hydrolyzes and acidifies the water body; then in the wetland unit Filtration and biodegradation, the drip irrigation system 6 is used to distribute water evenly, and the membrane guide system 7 is used to discharge silt to purify the water body.

[0038] The multi-functional combination pool is divided into upper and lower two-layer structure. The upper layer structure is a grid pool 4 with two grids, one grid is a mechanical grid, and the other is an artificial grid, which intercepts suspended solids and floating impurities; the lower structure is a hydrolysis acidification adjustment tank. Pool 5, the effluent of the upper grid pool flows to the bottom of the hydrolysis acidification pool by gravity thr...

Embodiment 2

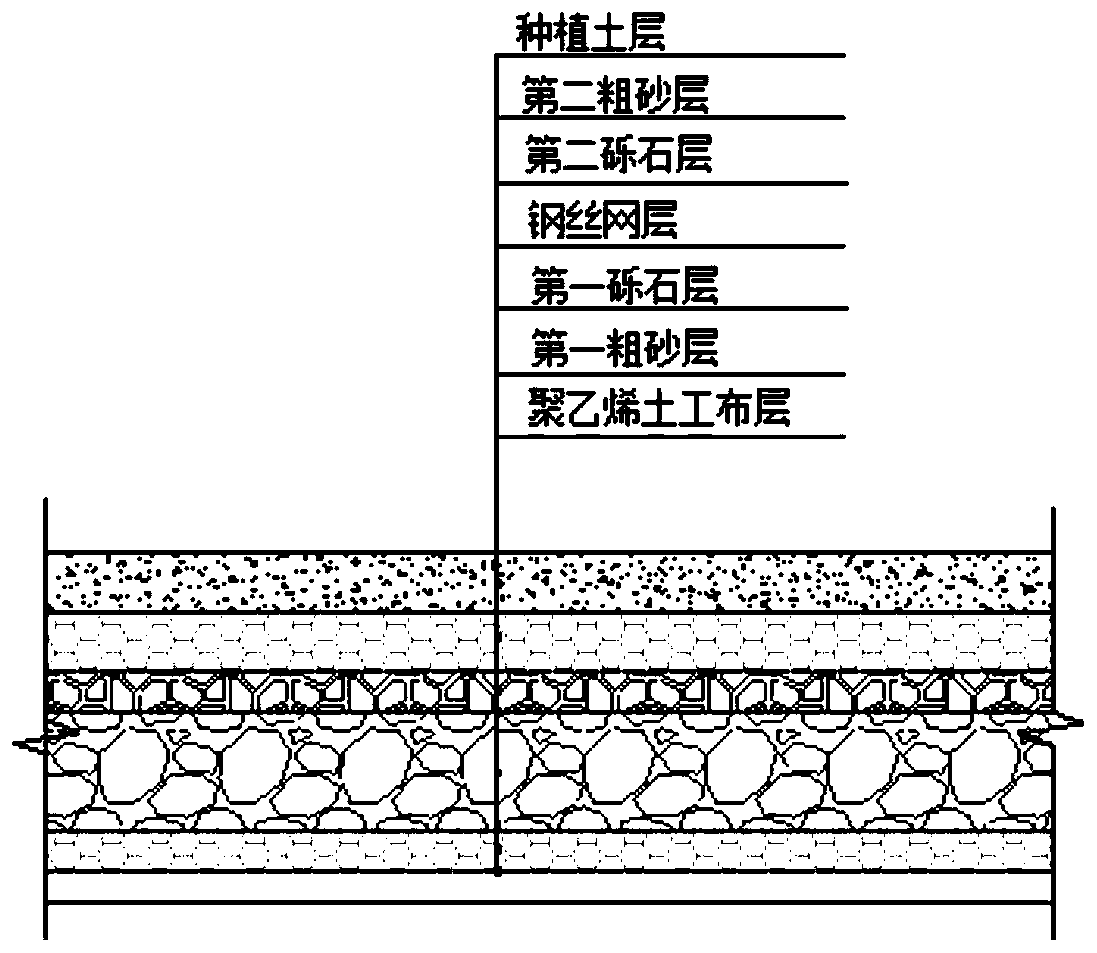

[0046] Such as figure 2 , 3 As shown, polyethylene geotextile layer, first coarse sand layer, first gravel layer, steel wire mesh layer, second gravel layer, second coarse sand layer, and planting soil layer are successively laid in the wetland unit from bottom to top.

[0047] Wherein, the polyethylene geotextile layer is laid with a polyethylene plastic film with a thickness of 0.5mm, and the geotextile with a liner density of 500g / m2 on both sides; the thickness of the first coarse sand layer is 100mm, and the thickness of the first gravel layer The thickness of the second gravel layer is 500mm, and the particle size of the gravel is φ100~150mm; the aperture of the steel wire mesh layer is 10*10mm, and the diameter of the steel wire is 0.6mm; the thick bottom of the second gravel layer is 200mm, and the particle size of the gravel is φ10-15mm; The thickness of the second coarse sand layer is 200mm; the thickness of the planting soil layer is 200mm, and the planting soil l...

Embodiment 3

[0057] In the early stage of constructed wetland operation, the fine clay particles in the filler and many silted SS together form a dense impermeable layer, and the extracellular polymer continuously condenses and adsorbs suspended or colloidal substrates of different particle sizes, thereby forming a large particle size The floc-like accumulations cause the accumulation of organic matter and inorganic matter, and block the pores of the filler. It is necessary to timely export the aging and falling off biofilm system, and regularly remove the sediment, intercepted matter and peeling generated during the operation of the wetland from the outlet pipe in the sump. The biofilm discharges the wetland unit to ensure the smooth flow of water in the wetland. When the film guide device is activated, close the valve on the outlet pipe of the artificial wetland sump, so that the filling in the wetland is in a state of full water infiltration, and use hydraulic infiltration for 24 hours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com