Self-heat-absorption anti-icing pavement and preparation method thereof

An anti-icing and shell technology, which is applied to roads, roads, pavement details, etc., can solve the problems of simple process, reduce the service life of the road surface, and cannot melt ice and snow, so as to ensure driving safety, prevent road surface from icing, and not easy to freeze Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

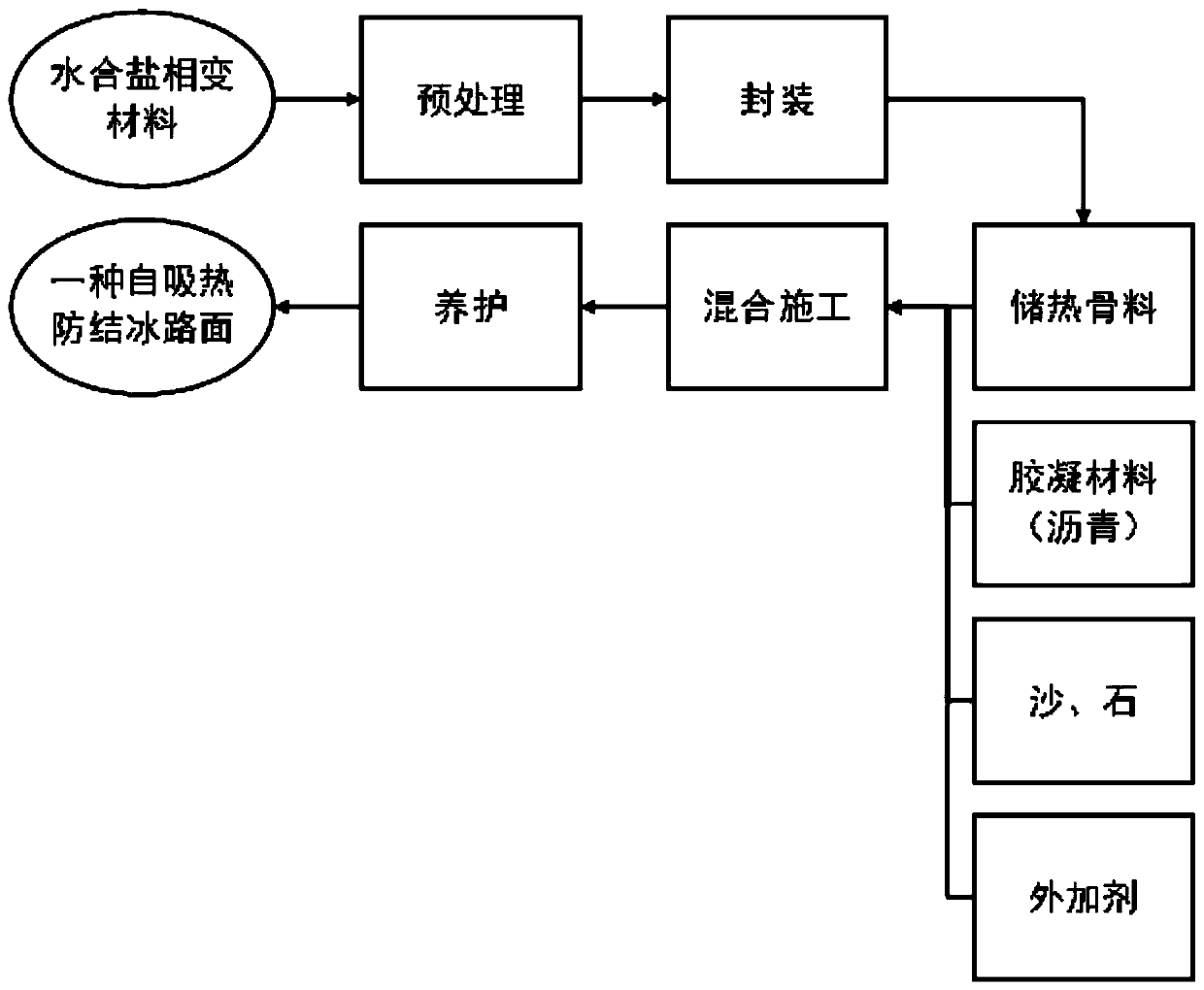

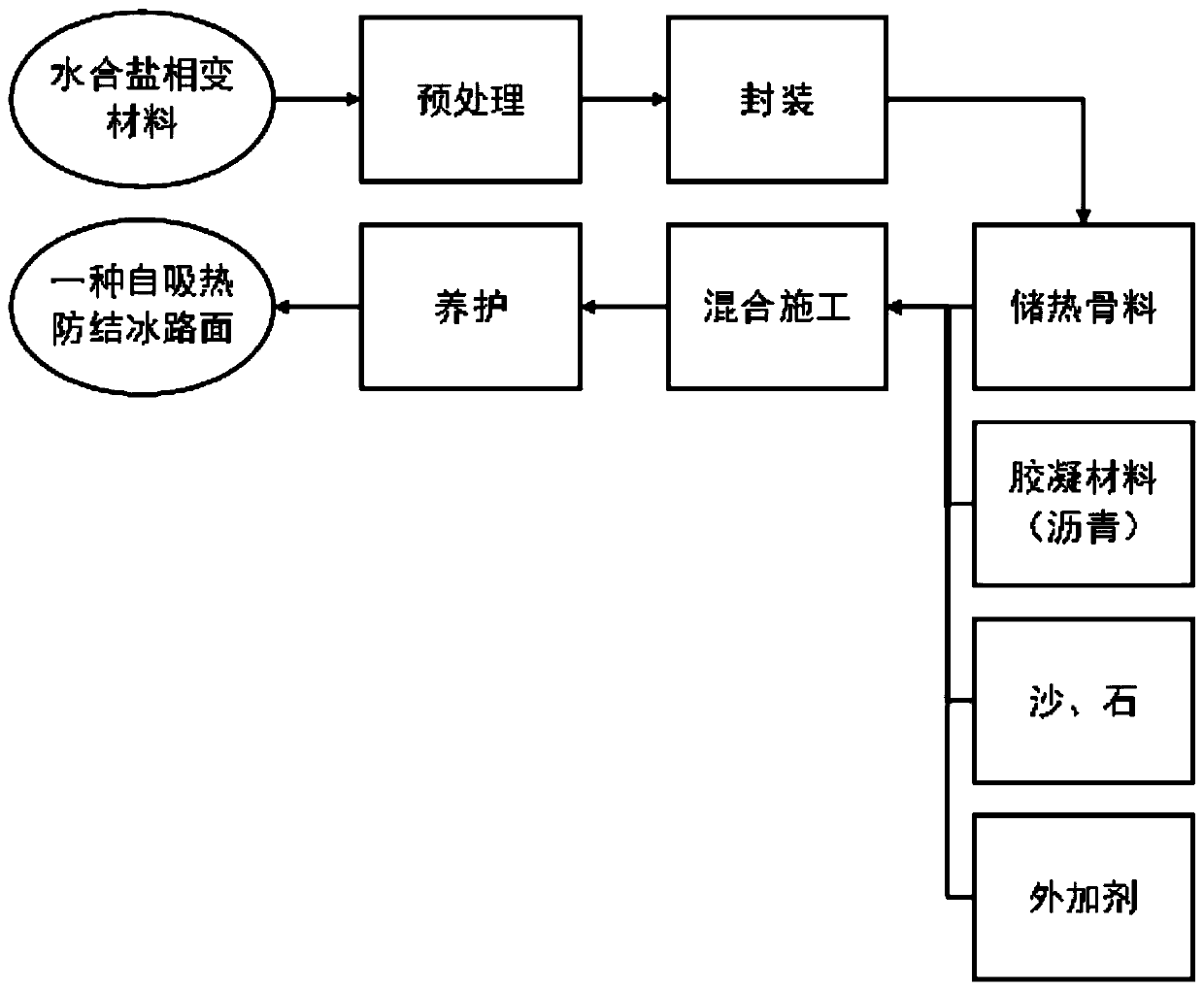

Method used

Image

Examples

Embodiment 1

[0029] (1) 66.6% calcium chloride hexahydrate compounded with 33.4% magnesium chloride hexahydrate is encapsulated in hollow steel balls to obtain steel balls rich in compound salts;

[0030] (2) Replace 30% of crushed stone with steel balls rich in compound salt, and prepare C50 concrete with a water-cement ratio of 0.4, in which the amount of P.O42.5 cement is 300kg m -3 , the amount of fly ash is 75kg·m -3 , the sand is 688kg·m -3 , steel ball 180kg·m -3 , gravel 860kg·m -3 , the water volume is 150kg·m -3 ;

[0031] (3) Dry mix cement and fly ash in a mixer for 20 seconds, add sand and continue mixing for 20 seconds, then add 1 / 3 water and stir for 60 seconds, add steel balls and gravel and the remaining 2 / 3 water, stir for 120 seconds, then Molded to produce a cube of 150mm×150mm×150mm, standard curing, measured its 28d strength ≥ 50MPa, thermal conductivity ≥ 2.5W / (m K), volume heat capacity including phase change heat ≥ 11.8 (MJ / m 3 · K). This example successfu...

Embodiment 2

[0033] (1) adsorption and encapsulation of zinc chloride trihydrate with fly ash porous ceramsite, obtain the fly ash porous ceramsite rich in zinc chloride trihydrate;

[0034] (2) Replace 100% of crushed stone with fly ash porous ceramsite rich in zinc chloride trihydrate, and the water-cement ratio is 0.5 to prepare C30 concrete, in which the amount of P.O42.5 cement is 300kg m -3 , the amount of fly ash is 120kg·m -3 , the sand is 688kg·m -3 , porous ceramsite 700kg m -3 , the water volume is 210kg·m -3 ;

[0035] (3) Dry mix cement and fly ash in a mixer for 20 seconds, add sand and continue mixing for 20 seconds, then add 1 / 3 water and stir for 60 seconds, add ceramsite and gravel and the remaining 2 / 3 water, stir for 120 seconds, then Molded to produce a cube of 150mm×150mm×150mm, standard curing, measured its 28d strength ≥ 30MPa, thermal conductivity ≥ 1.8034W / (m K), volumetric heat capacity including phase change heat ≥ 15.3 (MJ / m 3 · K). This example success...

Embodiment 3

[0037] (1) encapsulating potassium hydrogen phosphate hexahydrate with hollow sludge ceramsite to obtain hollow sludge ceramsite rich in potassium hydrogen phosphate hexahydrate;

[0038] (2) Replace 100% of gravel with hollow sludge ceramsite rich in potassium hydrogen phosphate hexahydrate, the water-cement ratio is 0.5, and prepare C20 alkali-activated concrete, and the amount of fly ash is 400kg m -3 , the sand is 700kg·m -3 , hollow sludge ceramsite 800kg m -3 , 10mol / L sodium hydroxide solution 200kg m -3 ;

[0039] (3) Stir fly ash and sodium hydroxide in a mixer for 60s, add ceramsite and stir for 120s, and then shape it to obtain a cube of 150mm×150mm×150mm, standard curing, its 28d strength is measured to be ≥20MPa, and its thermal conductivity ≥1.6034W / (m·K), volumetric heat capacity including phase change heat ≥13.2(MJ / m 3· K). In this example, phase change-alkali-activated concrete with a strength grade of C20 was successfully prepared. The solid-liquid phase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Volume heat capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com