Preparation method of efficient blue-light polyfluorene spherocrystal material

A technology of spherulite and blue light, which is applied in the field of preparation of high-efficiency blue light polyfluorene spherulite materials, can solve problems affecting device luminescence stability and device service life, and achieve good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

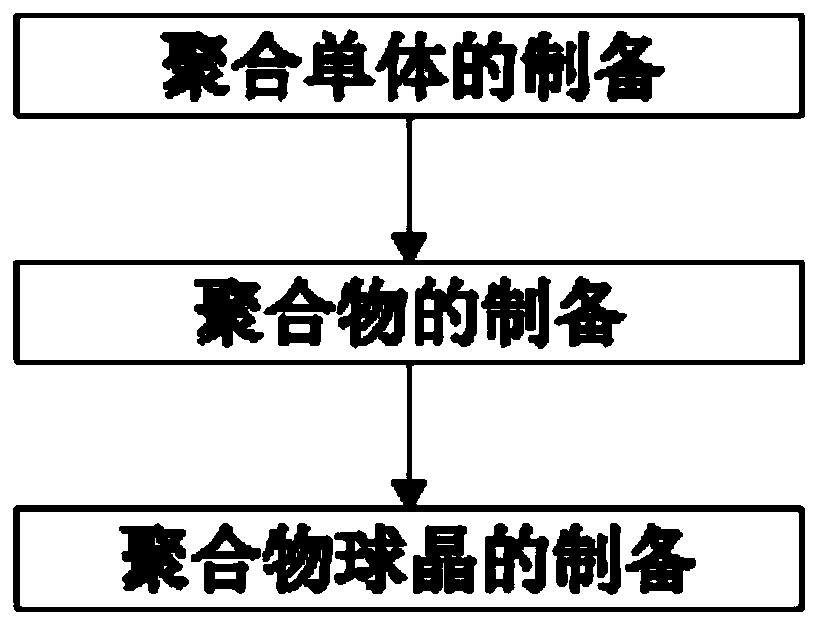

[0032] see Figure 1-3 , the present invention provides a technical solution: a method for preparing a high-efficiency blue-light polyfluorene spherulite material. The specific preparation steps of the high-efficiency blue-light polyfluorene spherulite material are as follows:

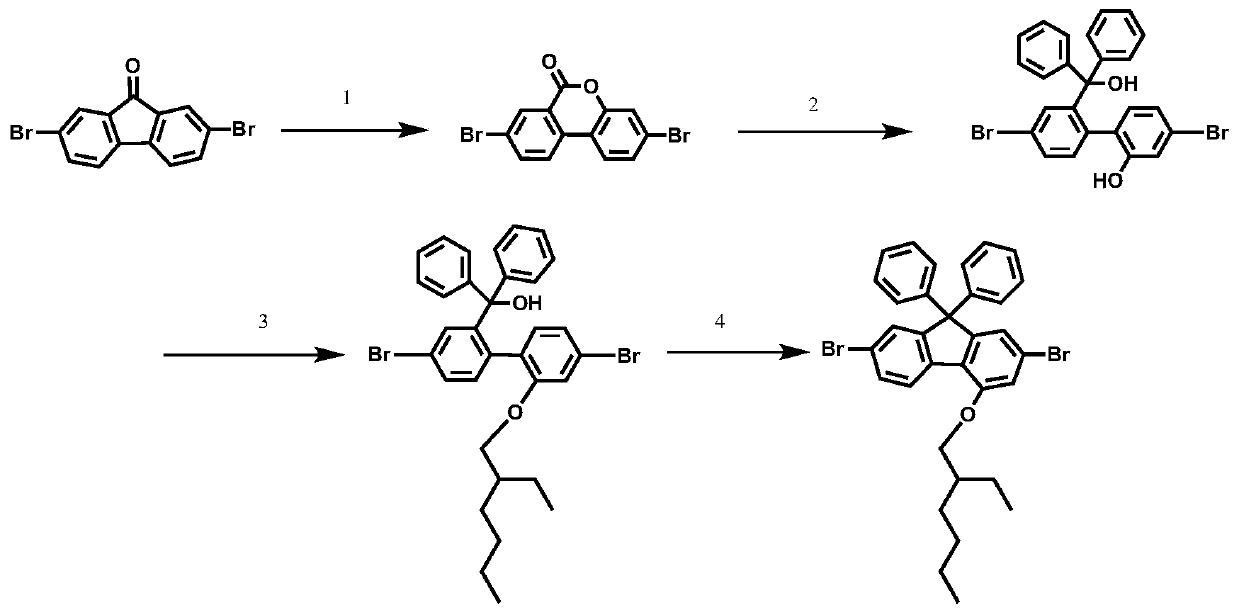

[0033] S1: Preparation of polymerized monomers:

[0034] a: Preparation of lactone from 2,7-dibromo-9-fluorenone by Bayer-Villiger rearrangement;

[0035] b: Lactone is prepared by Grignard reaction to 2,7-dibromodiol;

[0036] c: Alkyl substitution reaction of the 4th alcohol group of 2,7-dibromodiol;

[0037] d: The product of the previous step is produced by the Friedel-Crafts reaction as the main polymer monomer;

[0038] S2: Preparation of polymer: take equal amounts of bipyridine and nickel catalyst Ni(COD) 2 to fill N 2 In a two-necked flask, activate it in a DMF solution at 75°C for 20min, then add the polymerized monomer solution dissolved in toluene, reflux at 85°C for 3 days, then end-c...

Embodiment

[0049] The specific preparation steps of the preparation method of the high-efficiency blue light polyfluorene spherulite material are as follows:

[0050] S1: Preparation of polymerized monomers:

[0051] a: Prepare lactone from 2,7-dibromo-9-fluorenone by Bayer-Villiger rearrangement reaction, take 2.8g (8.28mmol) of 2,7-dibromofluorenone and dissolve it in 30ml of dry dichloromethane In, then add 25ml trifluoroacetic acid. Under ice bath conditions, add sodium percarbonate Na every 15min 2 CO 4 1g, 5 times in total. Then return to room temperature and stir for 72h, after the reaction is complete, use sodium bicarbonate NaHCO 4 The remaining trifluoroacetic acid was removed, extracted with dichloromethane and then purified with petroleum ether:dichloromethane (5:1) silica gel column to obtain a light yellow powdery solid (yield 85%);

[0052] b: 2,7-dibromodiol was prepared from lactone by Grignard reaction. First, take 12ml of bromobenzene and magnesium chips (1.76g, 72...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com