Environment-friendly beverage packaging bag and processing technology thereof

A packaging bag, environment-friendly technology, applied in the field of environment-friendly beverage packaging bags and their processing technology, can solve the problems that packaging bags cannot meet the requirements of beverage packaging, affect the mechanical properties of packaging bags, affect the antibacterial effect of packaging bags, etc., and achieve excellent Antioxidant and antibacterial properties, enhanced antioxidative and antibacterial capabilities, and enhanced activity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

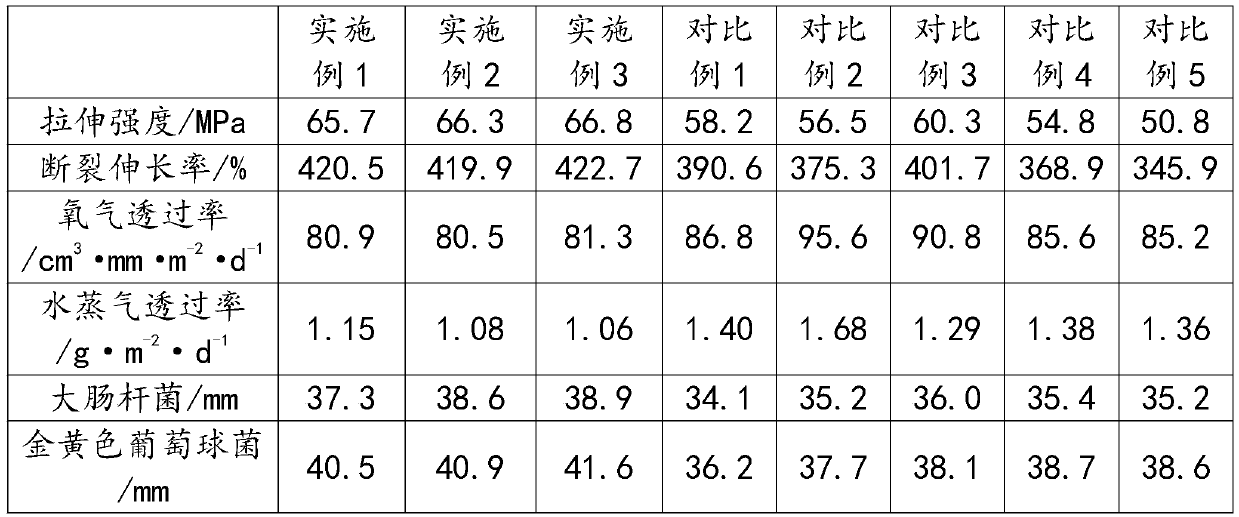

Examples

Embodiment 1

[0045] An environment-friendly beverage packaging bag, comprising the following raw materials in parts by weight: 50 parts of polybutylene succinate (PBS), 16 parts of polybutylene terephthalate adipate (PBAT), modified chitosan 2.6 parts of sugar, 2.2 parts of carbon nanotube whiskers, 1.8 parts of mica powder, 0.5 parts of coupling agent;

[0046] The packing bag is made by the following steps:

[0047] The first step, place polybutylene succinate, polybutylene terephthalate adipate and mica powder in a vacuum drying oven for 24 hours, mix well after drying, and use a torque rheometer to Under the conditions of 175°C and 50r / min, melt banburying was carried out, and the banburying time was 6min to obtain a polymer matrix;

[0048] The second step is to mix the coupling agent and absolute ethanol uniformly according to the volume ratio of 1:12 to obtain a dispersion; add carbon nanotube whiskers and modified chitosan to the dispersion, and stir and mix at 200r / min After 10 ...

Embodiment 2

[0052] An environment-friendly beverage packaging bag, comprising the following raw materials in parts by weight: 55 parts of polybutylene succinate (PBS), 17 parts of polybutylene terephthalate adipate (PBAT), modified chitosan 2.9 parts of sugar, 2.3 parts of carbon nanotube whiskers, 1.9 parts of mica powder, 0.6 parts of coupling agent;

[0053] The packing bag is made by the following steps:

[0054] The first step, place polybutylene succinate, polybutylene terephthalate adipate and mica powder in a vacuum drying oven for 24 hours, mix well after drying, and use a torque rheometer to Under the conditions of 180°C and 50r / min, melt banburying was carried out, and the banburying time was 6.5min to obtain a polymer matrix;

[0055] The second step is to mix the coupling agent and absolute ethanol uniformly according to the volume ratio of 1:13 to obtain a dispersion; add carbon nanotube whiskers and modified chitosan to the dispersion, and stir and mix at 200r / min After 1...

Embodiment 3

[0059] An environment-friendly beverage packaging bag, comprising the following raw materials in parts by weight: 60 parts of polybutylene succinate (PBS), 18 parts of polybutylene terephthalate adipate (PBAT), modified chitosan 3.2 parts of sugar, 2.5 parts of carbon nanotube whiskers, 2 parts of mica powder, 0.7 parts of coupling agent;

[0060] The packing bag is made by the following steps:

[0061] The first step, place polybutylene succinate, polybutylene terephthalate adipate and mica powder in a vacuum drying oven for 24 hours, mix well after drying, and use a torque rheometer to Under the conditions of 185°C and 50r / min, melt banburying was carried out, and the banburying time was 7min to obtain a polymer matrix;

[0062] The second step is to mix the coupling agent and absolute ethanol uniformly according to the volume ratio of 1:15 to obtain a dispersion; add carbon nanotube whiskers and modified chitosan to the dispersion, and stir and mix at 200r / min After 15 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com