Gas diffusion layer for fuel cell as well as preparation method and application of gas diffusion layer

A gas diffusion layer, fuel cell technology, applied in fuel cells, electrical components, battery electrodes, etc., can solve problems such as increased impedance and decreased durability, and achieves the goal of avoiding flooding, reducing workload, and avoiding proton conductivity decline. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

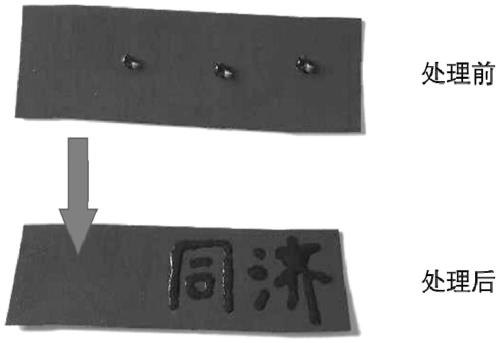

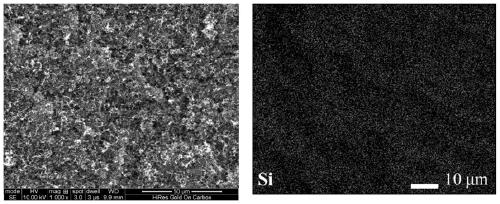

[0043]Hydrophobic treatment: use polytetrafluoroethylene as a hydrophobic agent to soak the support layer of the gas diffusion layer; prepare the microporous layer of the gas diffusion layer with a ratio of conductive carbon black and hydrophobic agent of 5:1.

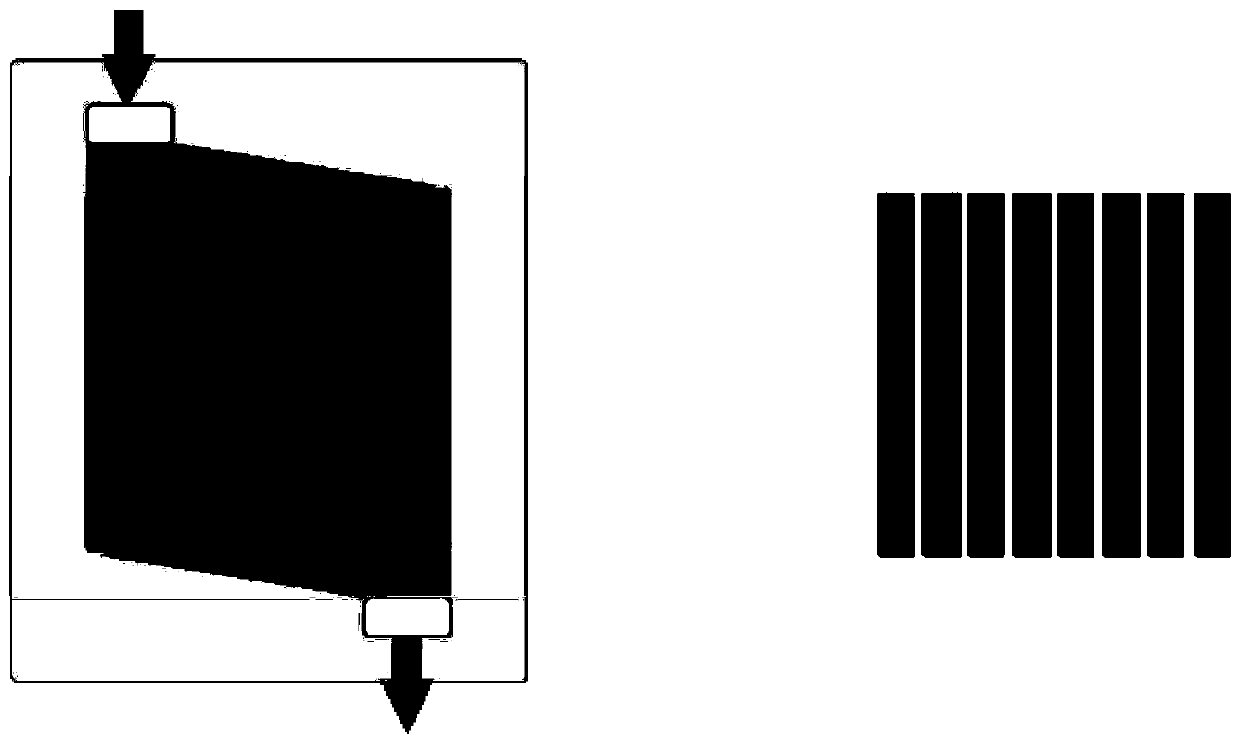

[0044] Hydrophilic structure design: The selected small molecule is isopropyl tris(dioctyl pyrophosphate acyloxy) titanate, and the hydrophilic region is designed as image 3 Shown, the preparation method of hydrophilic region comprises the following steps:

[0045] a) using a mixed solution of deionized water and ethanol as a solvent, wherein the deionized water accounts for 5% of the mixed solution mass;

[0046] b) adjusting the pH value of the mixed solution to 6;

[0047] c) Put the small molecule used for self-assembly of the hydrophilic region into the above mixed solution, and stir for 20 minutes to obtain the precursor solution of the hydrophilic region, the mass proportion of the small molecule is 1%;

[00...

Embodiment 2

[0051] Hydrophobic treatment: use polytetrafluoroethylene as a hydrophobic agent to soak the support layer of the gas diffusion layer; prepare the microporous layer of the gas diffusion layer with a ratio of conductive carbon black to hydrophobic agent of 4:1.

[0052] Hydrophilic structure design: The selected small molecule is γ-glycidyloxypropyltrimethoxysilane, and the hydrophilic region is designed as image 3 Shown, the preparation method of hydrophilic region comprises the following steps:

[0053] a) using a mixed solution of deionized water and ethanol as a solvent, wherein deionized water accounts for 50% of the mixed solution mass;

[0054] b) adjusting the pH value of the mixed solution to 4;

[0055] c) Put the small molecule used for self-assembly of the hydrophilic region into the above mixed solution, and stir for 10 minutes to obtain the precursor solution of the hydrophilic region, the mass proportion of the small molecule is 2%;

[0056] d) Coating a hydro...

Embodiment 3

[0059] Hydrophobic treatment: use polyvinylidene fluoride as a hydrophobic agent to soak the support layer of the gas diffusion layer; prepare the microporous layer of the gas diffusion layer with a ratio of conductive carbon black to hydrophobic agent of 5:1.

[0060] Hydrophilic structure design: The selected small molecule is γ-methacryloxypropyltrimethoxysilane, and the hydrophilic region is designed as Figure 4 Shown, the preparation method of hydrophilic region comprises the following steps:

[0061] a) using a mixed solution of deionized water and ethanol as a solvent, wherein deionized water accounts for 30% of the mixed solution mass;

[0062] b) adjusting the pH value of the mixture to 2;

[0063] c) Put the small molecule used for self-assembly of the hydrophilic region into the above mixed solution, and stir for 30 minutes to obtain the precursor solution of the hydrophilic region, the mass proportion of the small molecule is 0.5%;

[0064] d) Coating a hydrophi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com