Method for preventing metal ion migration on surface of PCB

A metal ion, PCB board technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

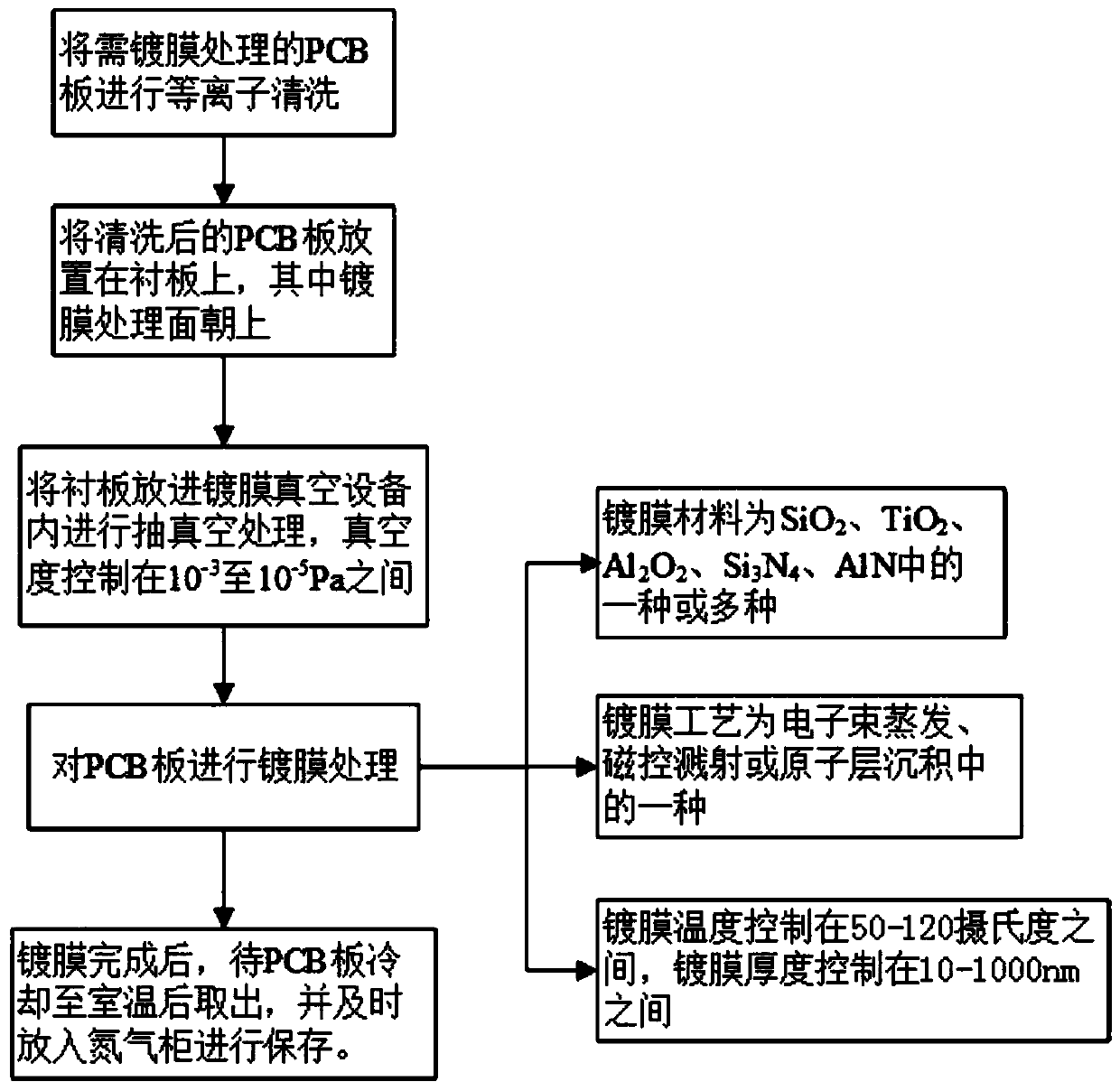

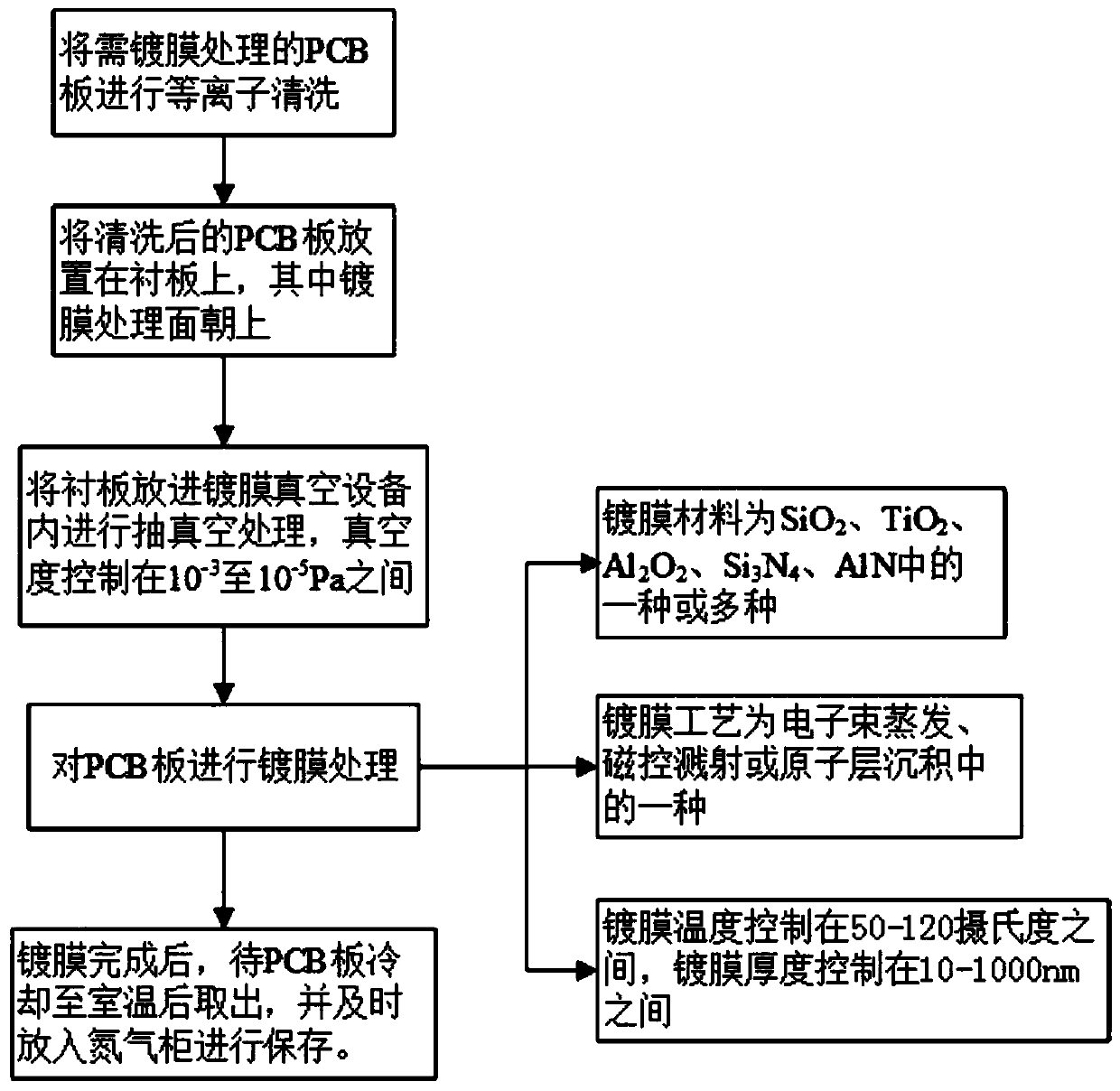

[0027] Such as figure 1 As shown, what the present invention mainly relates to is the vacuum coating process, and the vacuum coating process is used to ensure that the required inert protective layer is prepared uniformly under a low temperature and dust-free environment.

[0028] The preparation method is as follows:

[0029] S1: Plasma cleaning the PCB board to be coated;

[0030] S2: Place the cleaned PCB on the liner, with the coated surface facing up;

[0031] S3: Put the lining board into the coating vacuum equipment for vacuum treatment, and the vacuum degree is controlled at 10 -3 to 10 -5 Between Pa;

[0032] S4: Coating the PCB board, the coating material is SiO 2 、TiO 2 、Al 2 o 2 、Si 3 N 4 , one or more of AlN, the coating process is one of electron beam evaporation, magnetron sputtering or atomic layer deposition, and the coating temperature is controlled between 50-120 degrees Celsius;

[0033] S5: After the coating is completed, take out the PCB board ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com