Polyimide powder, polyimide varnish and polyimide film

A technology of polyimide powder and polyimide, which is applied in the field of polyimide varnish, polyimide film and polyimide powder, and can solve the problem of reducing the mechanical properties of polyimide film, polyimide Achieve excellent heat resistance, mechanical properties, and excellent transparency due to problems such as changes in the viscosity of imine varnishes and changes in the degree of polymerization of polyamic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

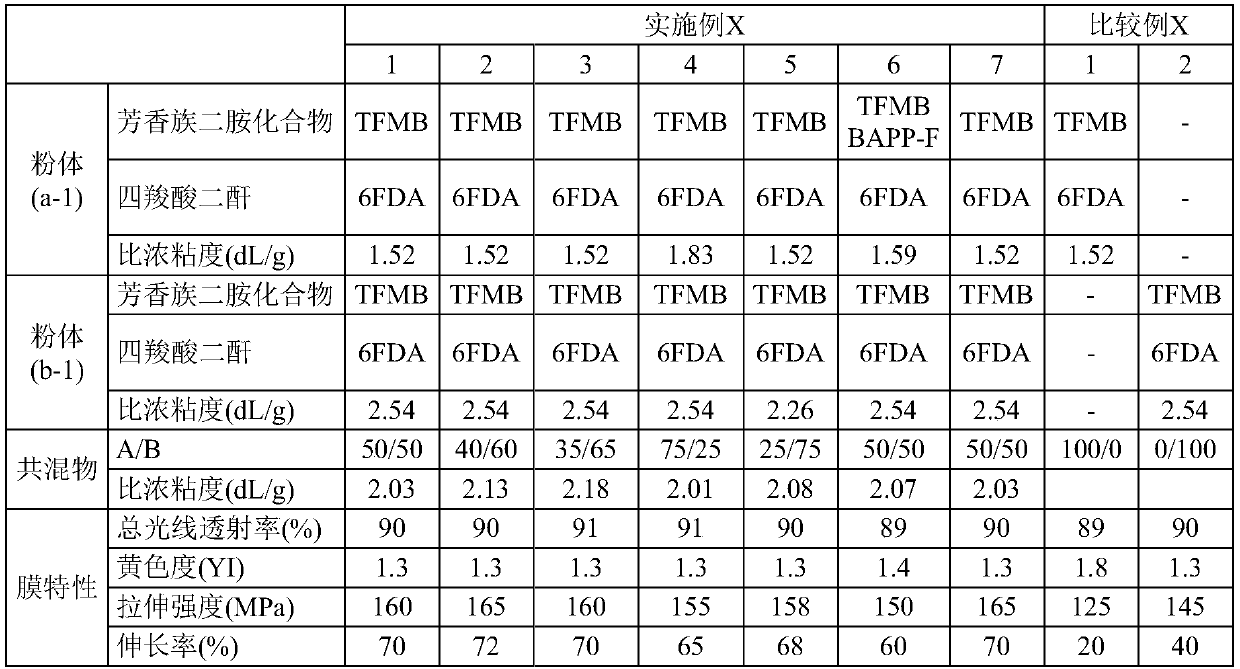

[0094] Hereinafter, the present invention will be specifically described by way of examples, but the present invention is not limited to these examples.

[0095] (Measurement method of reduced viscosity of polyimide)

[0096] The polyimide powder was dissolved in N,N-dimethylacetamide (DMAC) at a concentration of 0.5 g / dL to prepare a polyimide solution. The outflow time (T) of the polyimide solution and the outflow time (T0) of only the solvent DMAC were measured at a temperature of 30° C. using an Ubbelohde viscometer, and the reduced viscosity was obtained from the following formula.

[0097] Reduced viscosity (dL / g) = (T-T0) / T0 / 0.5

[0098] (Measurement method of weight average molecular weight of polyimide)

[0099] Prepare a tetrahydrofuran solution of polyimide at a concentration of 1 mg / mL, and use a size exclusion chromatography device (HLC-8320GPC manufactured by Tosoh Corporation) in an eluent: tetrahydrofuran (without stabilizer), column: TSKgel SuperHM-M (2 in ...

Embodiment X1

[0112] Add 461 g of solvent N,N-dimethylacetamide (DMAC) (containing 100 ppm of water; the following is used in all of Example X and Comparative Example X) in a glass 2L detachable flask equipped with a stirring device and stirring blades The same is true for DMAC) and 2,2'-bis(trifluoromethyl)-4,4'-diaminobiphenyl (TFMB) 64.047 g (0.2000 mol) of an aromatic diamine compound having a fluorine group were stirred, TFMB was dissolved in DMAC. Next, 4,4'-(1,1,1,3,3,3-hexafluoropropane-(1,1,1,3,3,3-hexafluoropropane- 2,2-diyl) bisphthalic anhydride (6FDA) 89.737g (0.2020 mol), in this state adjust the temperature to the temperature range of 20 ℃ ~ 40 ℃, while continuing to stir for 6 hours to carry out the polymerization reaction, to obtain Viscous polyamic acid solution. The tetracarboxylic dianhydride / aromatic diamine compound molar ratio used was 1.01, and the concentration of the polyamic acid solution was 25% by weight.

[0113] 410 g of DMAC was added to the obtained polya...

Embodiment X2

[0122] Using 16 g of the polyimide powder (a-1) obtained in Example X1, which is composed of polyimide with a reduced viscosity of 1.52 dL / g, is composed of polyimide with a reduced viscosity of 2.54 dL / g. The polyimide powder (b-1) 24g, the blending ratio of polyimide powder (a-1) and polyimide powder (b-1) is set as polyimide powder (b-1) by weight ratio Except imide powder (a-1) / polyimide powder (b-1)=40 / 60, it carried out similarly to Example X1.

[0123] The reduced viscosity measured about the obtained polyimide powder was 2.13 dL / g, and the average particle diameter was 0.06 mm. In addition, a polyimide film with a thickness of 50 μm obtained from the polyimide powder had a total light transmittance of 90%, a yellowness of 1.3, and extremely excellent transparency. In addition, the tensile strength of the polyimide film was 165 MPa. The elongation was excellent at 72%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reduced viscosity | aaaaa | aaaaa |

| Reduced viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com