Ursodesoxycholic acid capsule and preparation method thereof

A technology of ursodeoxycholic acid and capsules, which is applied in the field of ursodeoxycholic acid capsules and its preparation, can solve the problems of great influence on the viscosity of starch slurry, differences between product batches, and high granule strength, and achieve easy control of granule size, The effect of small batch-to-batch variation and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The impact of embodiment 1 different processes on product stripping

[0048] In this example, under the condition that the components and dosage of ursodeoxycholic acid capsules are the same, the influence of different production processes on the dissolution of the product is studied. The specific process parameters are shown in Table 1.

[0049] Table 1 List of different granulation process parameters

[0050]

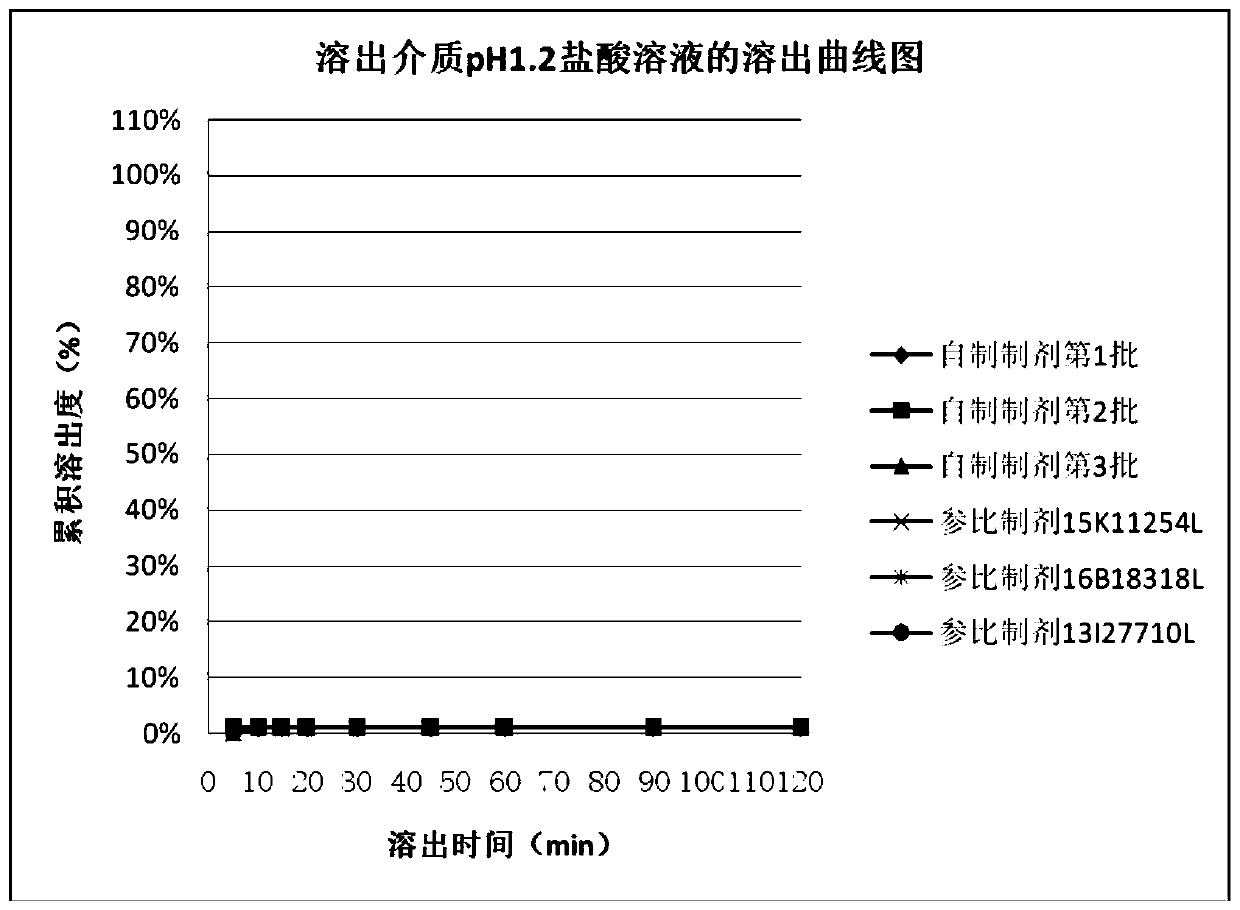

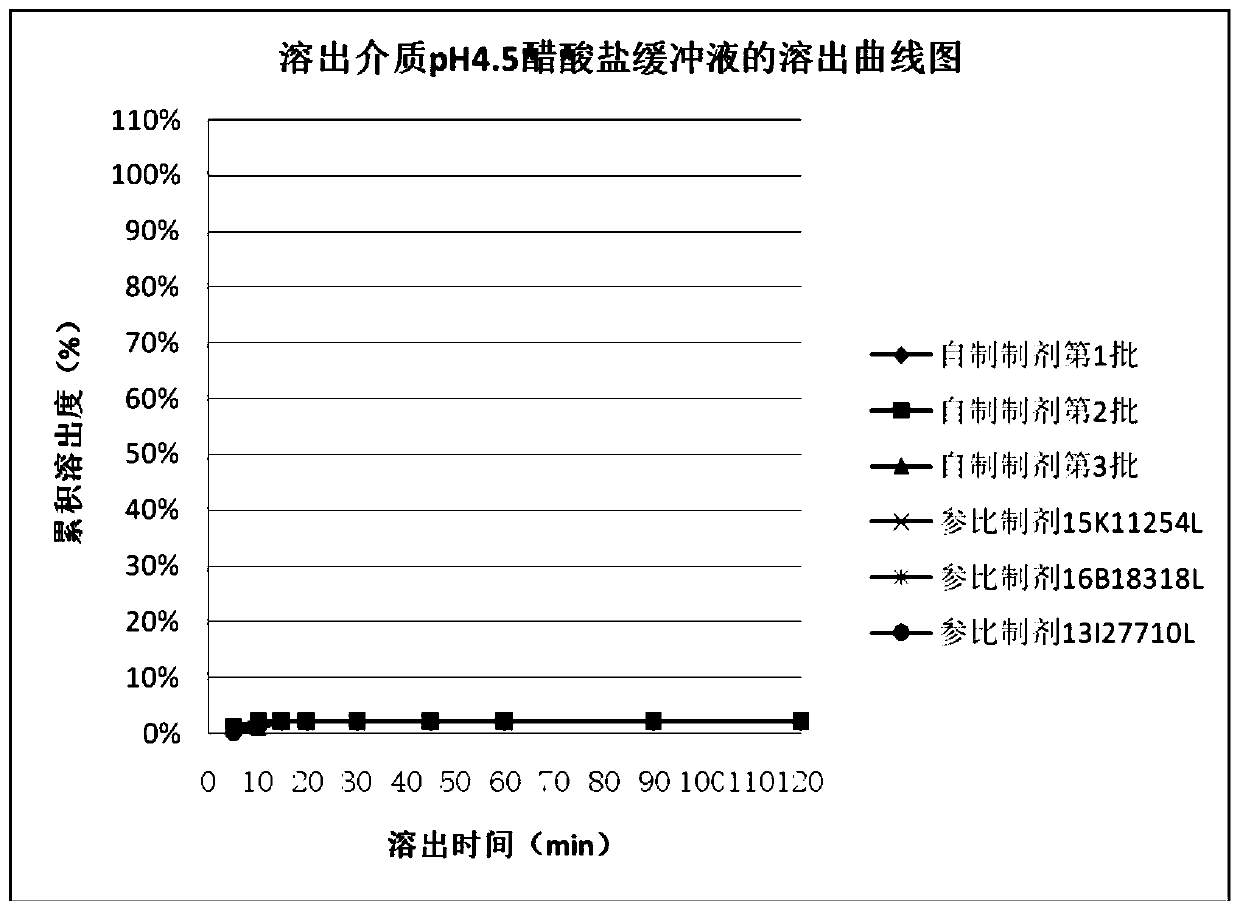

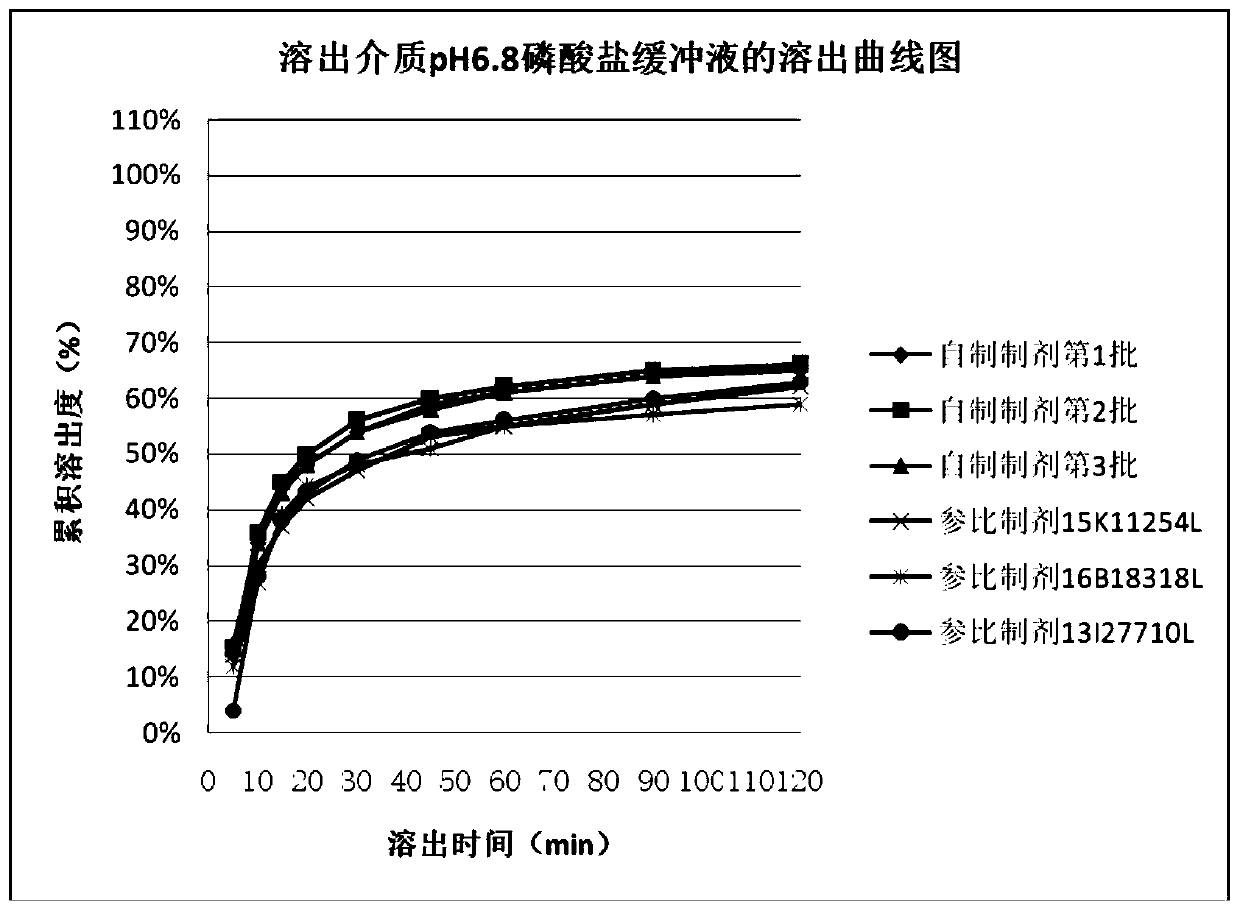

[0051] Determination of the dissolution curves of ursodeoxycholic acid capsules prepared according to the above-mentioned granulation process and the reference preparation Ursifer, and using the similarity factor f 2 The evaluation results are shown in Table 2.

[0052] Table 2 Dissolution curve data of different production processes

[0053]

[0054] Result analysis:

[0055] Powder mixed directly: the content density is low, so it needs to be filled with 00# capsules, the capsules are too big to be swallowed, and the dissolution profile is not simila...

Embodiment 2

[0059] The impact of embodiment 2 different raw material particle diameters on product stripping

[0060] In this example, under the condition that the components and dosages of ursodeoxycholic acid capsules are the same, the effect of different raw material particle sizes on the dissolution of the product is studied. The specific raw material particle size parameters are shown in Table 3.

[0061] Table 3 List of particle sizes of different raw materials

[0062]

[0063] The preparation method of the ursodeoxycholic acid capsule of the present embodiment comprises the following steps:

[0064] (1) Add ethanol to purified water, add povidone K30 after mixing, stir until the povidone K30 is completely dissolved, the solution is in a clear state, and an adhesive solution is obtained, which is set aside;

[0065] (2) The ursodeoxycholic acid raw material is passed through a 20-mesh sieve, the microcrystalline cellulose and lactose are passed through a 40-mesh sieve, and set ...

Embodiment 3

[0073] The influence of embodiment 3 different fillers on product stripping

[0074] To study the influence of different fillers on product dissolution, the specific prescription of the contents of ursodeoxycholic acid capsules is shown in Table 5.

[0075] Table 5 List of prescriptions for different fillers

[0076]

[0077]

[0078] The preparation method of ursodeoxycholic acid capsules with different fillers in this embodiment comprises the following steps:

[0079] (1) Add ethanol to purified water, add povidone K30 after mixing, stir until the povidone K30 is completely dissolved, the solution is in a clear state, and an adhesive solution is obtained, which is set aside;

[0080] (2) Raw materials of ursodeoxycholic acid with a size of 18μm≤d50≤50μm and 80μm≤d90≤250μm were passed through 20 meshes, lactose from prescription 6, mixture of microcrystalline cellulose and lactose from prescription 7, and microcrystalline cellulose from prescription 8 were all passed t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com