Zirconolite type ceramic solidified body and preparation method and application thereof

A technology of ceramic solidification and perovskite zirconium, which is applied in the field of ceramic materials, can solve the problems of high energy consumption, complicated process, and long time consumption, and achieve the effects of low energy consumption, simple process, and less time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The raw materials of calcium titanate, nano-titanium dioxide (with a particle size of 60nm), and zirconia are taken in a mass ratio of 38:34:22. The above mixed powder is added to absolute ethanol and zirconia balls, mixed on a roller ball mill for 20 hours, and the mixed powder obtained after drying is formed by dry pressing at 30 MPa to obtain a pottery embryo, and then put the pottery embryo into a microwave sintering furnace , heated up to 1400°C at 40°C / min, held for 10 minutes, cooled down to 800°C at 40°C / min, and then cooled with the furnace to obtain a perovskite-zircon ceramic solidified body (CaZrTi 2 o 7 )

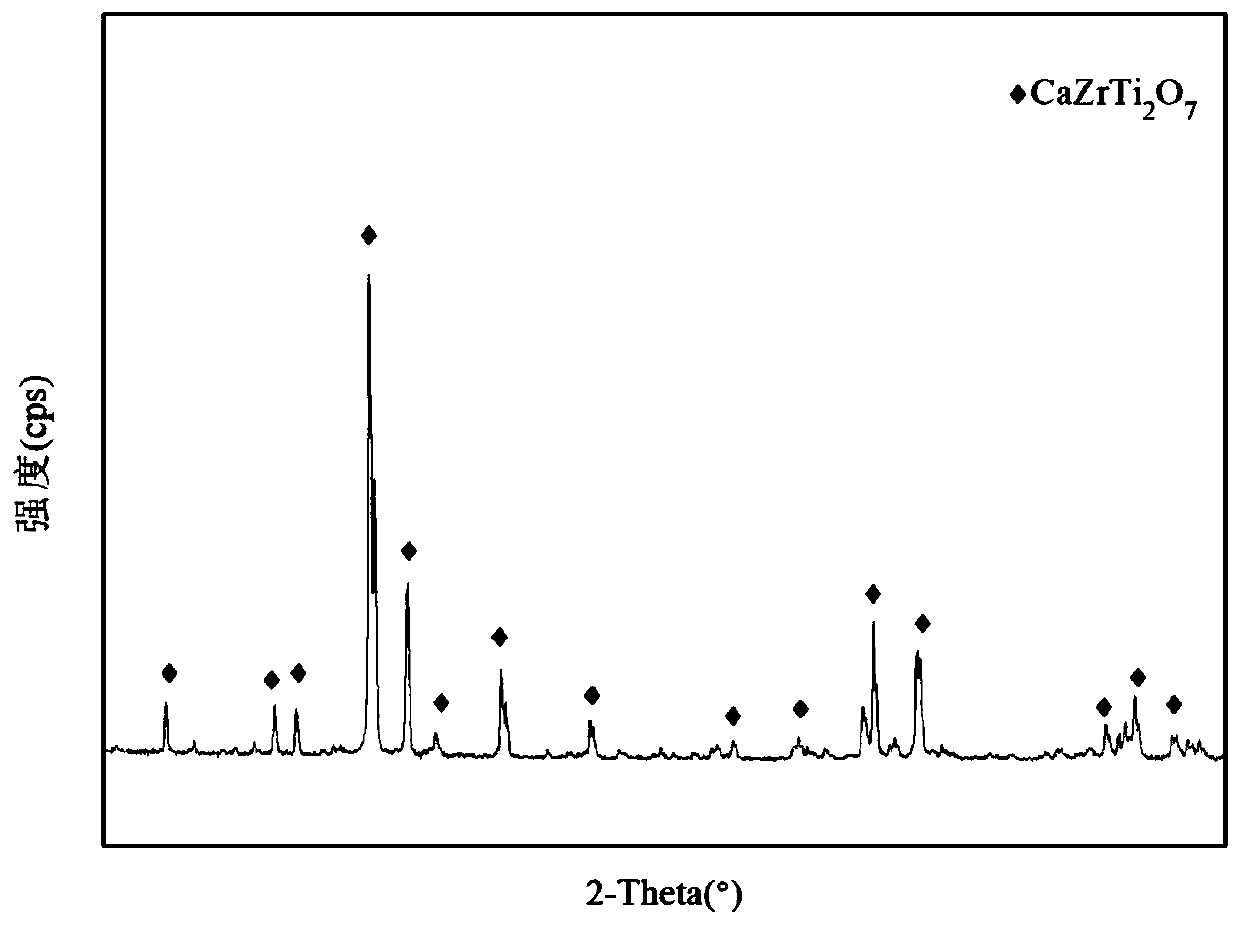

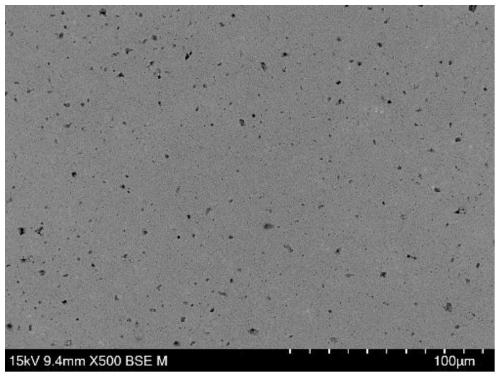

[0032] figure 1 The perovskite zircon type ceramic solidified body (CaZrTi 2 o 7 ) XRD pattern. From figure 1 It can be seen that the reaction is complete, no impurity phase is formed, and the obtained sample is CaZrTi 2 o 7 pure phase. figure 2 The SEM photo of the perovskite-zircon type ceramic solidified body section that the present embodim...

Embodiment 2

[0034] The difference from Example 1 is that the mass ratio of calcium titanate, nano-titanium dioxide (60nm in particle size) and zirconia is 40:36:24, and the conditions of the sintering process: the temperature is raised to 1400°C at 30°C / min, Insulate for 10 minutes, cool down to 800°C at 30°C / min and then cool with the furnace, the main phase of the prepared sample is CaZrTi 2 o 7 , to prepare perovskite zircon type ceramic solidified body (CaZrTi 2 o 7 ), electron microscope results showed that the samples were sintered uniformly.

Embodiment 3

[0036] The difference from Example 1 is: with calcium hydroxide powder, nano titanium dioxide powder (particle size is 60nm), zirconia powder as raw material, get each raw material by the ratio of calcium hydroxide 40g, nano titanium dioxide 36g, zirconia 24g . The sintering process is: heat up to 1300°C at 30°C / min, hold for 1 hour, cool down to 800°C at 30°C / min, and then cool with the furnace to obtain a perovskite-zircon ceramic solidified body (CaZrTi 2 o 7 ), electron microscope results show that the sample has fewer pores and more uniform sintering.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com