Anti-allergic sulfated polysaccharide and preparation method and application thereof

A sulfuric acid polysaccharide, anti-allergic technology, applied in allergic diseases, polysaccharide/gum-containing food ingredients, applications, etc., can solve the problem of low anti-allergic activity, achieve the effects of reducing production costs, low energy consumption, and improving retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

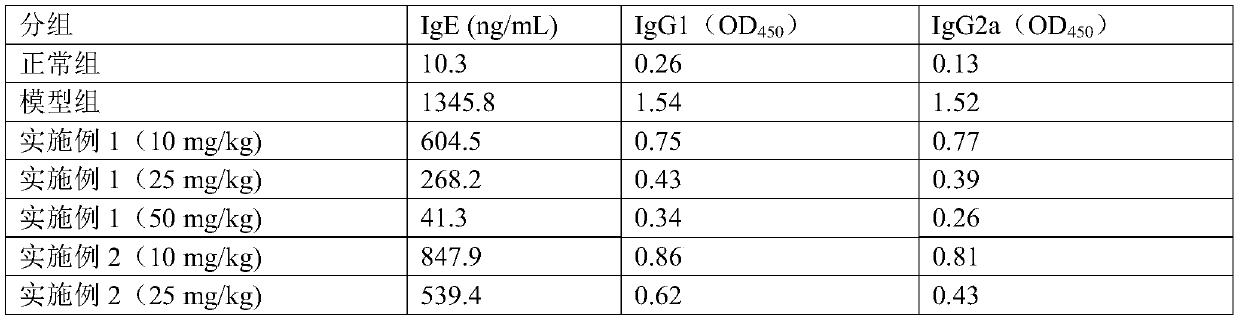

Examples

Embodiment 1

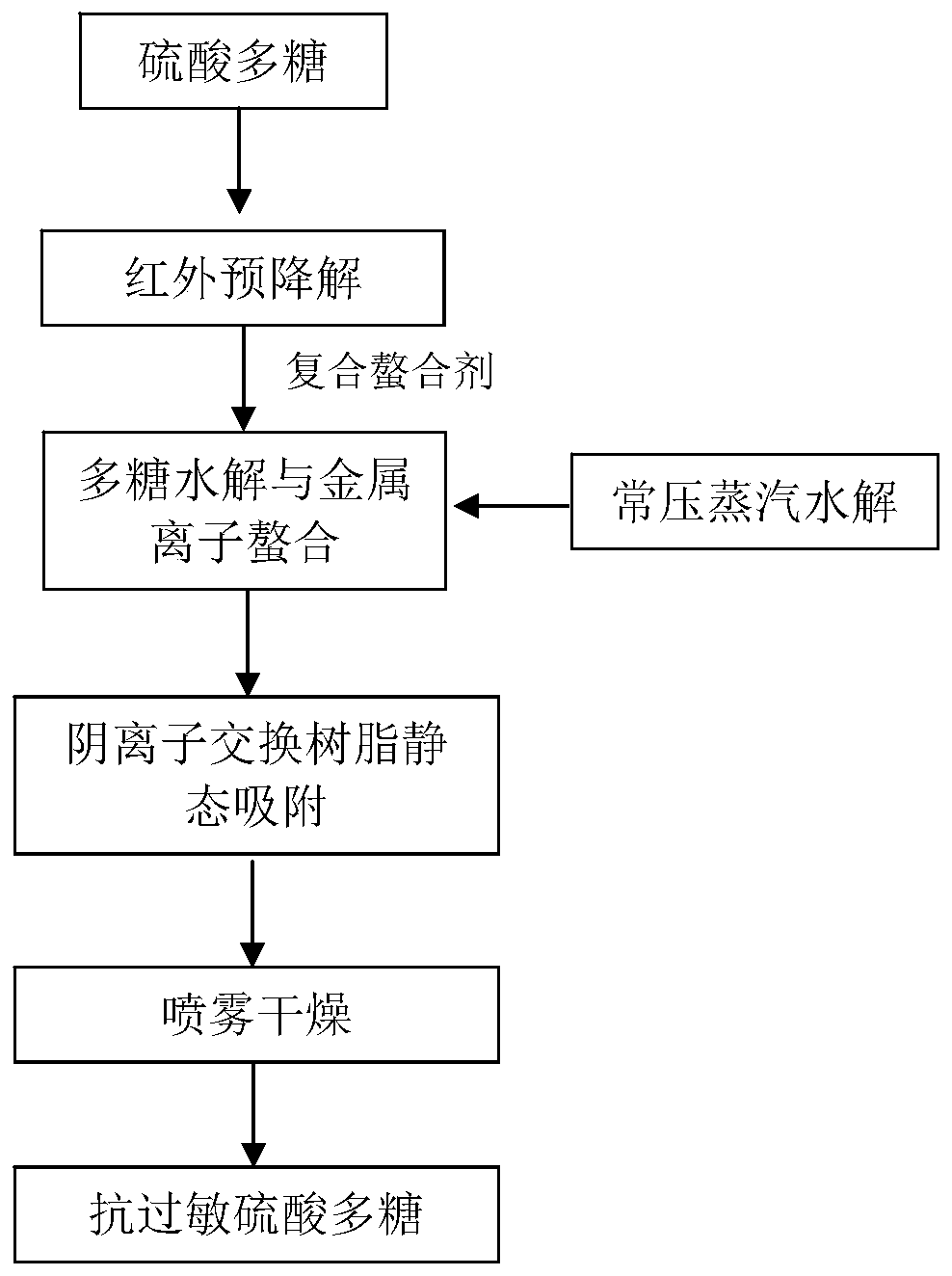

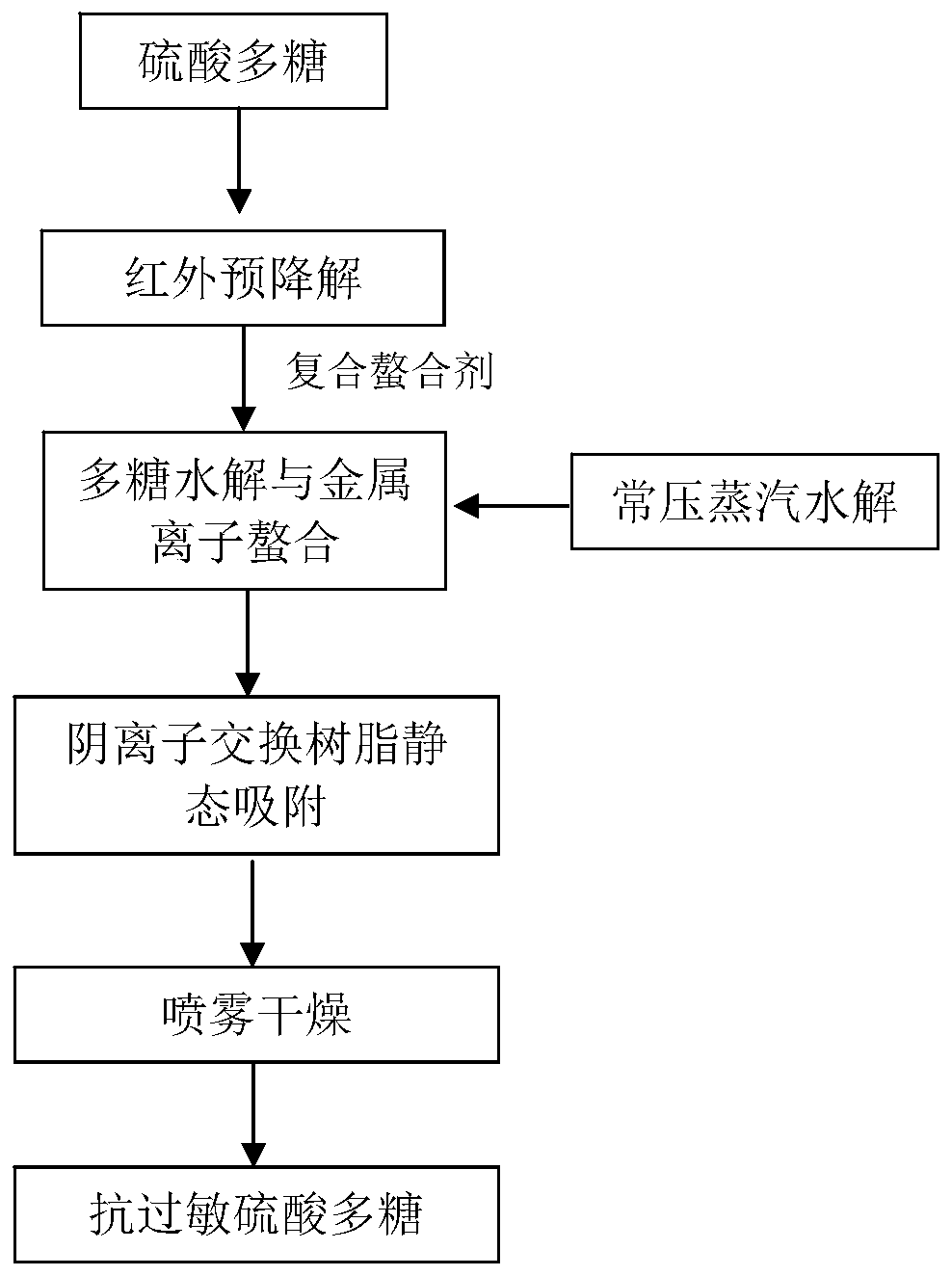

[0041] Preparation of anti-allergic fucoidan, refer to figure 1 ,Proceed as follows:

[0042] S1. Fucoidan solid-state infrared pre-degradation: Fucoidan derived from kelp (sulfate group is 35.4% by mass; calcium, magnesium, and manganese element contents are 12000mg / kg, 6540mg / kg, and 10500mg / kg respectively) Add deionized water to the dry powder, the amount of water added is 20% by mass, and then the wet fucoidan powder is prepared into a cake crust with a thickness of 0.1cm and spread on a clean stainless steel tray, and then put the tray into an infrared drying box, Keep the distance between the polysaccharide cake and the infrared lamp at 10 cm; use 3000w to heat for 1 hour to obtain dry pre-degraded fucoidan powder.

[0043] S2. Preparation of compound chelating agent: mix citric acid, polyaspartic acid, tartaric acid, sodium ethylenediamine tetraacetate (EDTA) and sodium pyrophosphate in a mass ratio of 3:3:2:1:1 to prepare a compound Chelating agent.

[0044] S3. Sy...

Embodiment 2

[0048] The preparation of antiallergic galactan sulfate, the steps are as follows:

[0049] S1, galactan sulfate solid-state infrared pre-degradation: the galactan sulfate (sulfate group is 11.2 mass %; calcium, magnesium, manganese element content is respectively 9870mg / kg, 4820mg / kg, 8960mg) / kg) dry powder was added deionized water, the amount of water added was 20% by mass, and then the galactan sulfate wet powder mass was prepared into a cake with a thickness of 0.1cm and spread on a clean stainless steel tray, and then put the tray into the infrared In the drying oven, keep the distance between the polysaccharide cake and the infrared lamp at 10 cm; use 3000w to heat for 1 hour to obtain the dry powder of pre-degraded galactan sulfate.

[0050] S2. Preparation of compound chelating agent: mix citric acid, polyaspartic acid, tartaric acid, sodium ethylenediamine tetraacetate (EDTA) and sodium pyrophosphate in a mass ratio of 3:3:2:1:1 to prepare a compound Chelating agen...

Embodiment 3

[0055] The preparation of antiallergic sulfated polysaccharides comprises the following steps:

[0056] S1: Carry out solid-state infrared pre-degradation of sulfated polysaccharides, add deionized water to sulfated polysaccharide dry powder (sulfated polysaccharide dry powder is obtained by extracting sulfated polysaccharides from Micrococcus and drying), to obtain sulfated polysaccharide wet powder, sulfated polysaccharide wet powder The sulfuric acid polysaccharide content in medium is 25% by mass, and the wet powder is made into dough, flattened into a cake skin with a thickness of 0.12cm, spread on a clean stainless steel tray, and then put the tray into an infrared drying box to make the cake skin and The distance of the infrared lamp is kept at 10cm; the infrared drying oven is selected at 2800w, and heated for 1h to obtain the pre-degraded sulfated polysaccharide dry powder;

[0057] S2: preparing a compound chelating agent, mixing citric acid, polyaspartic acid, tarta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| escape rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com